A kind of ni-co/cu superhydrophobic coating and preparation method thereof

A super-hydrophobic, ni-co technology, applied in the field of electrodeposition composite coating, can solve the problems of limited improvement of anti-corrosion life, and achieve the effect of prolonging the protection life, improving the protection effect and improving the anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

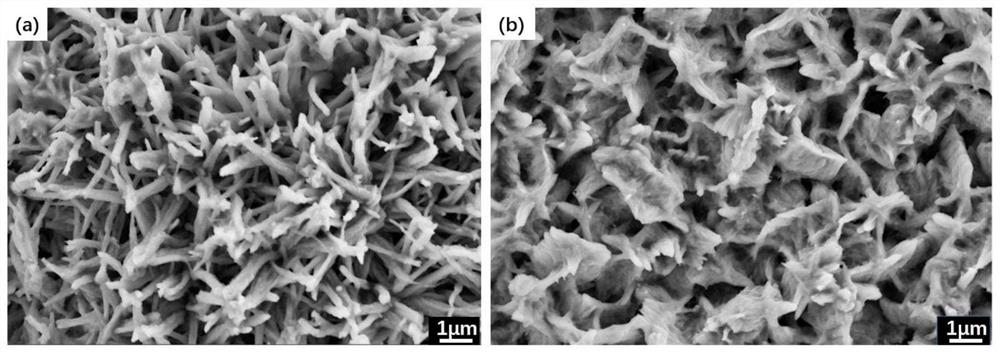

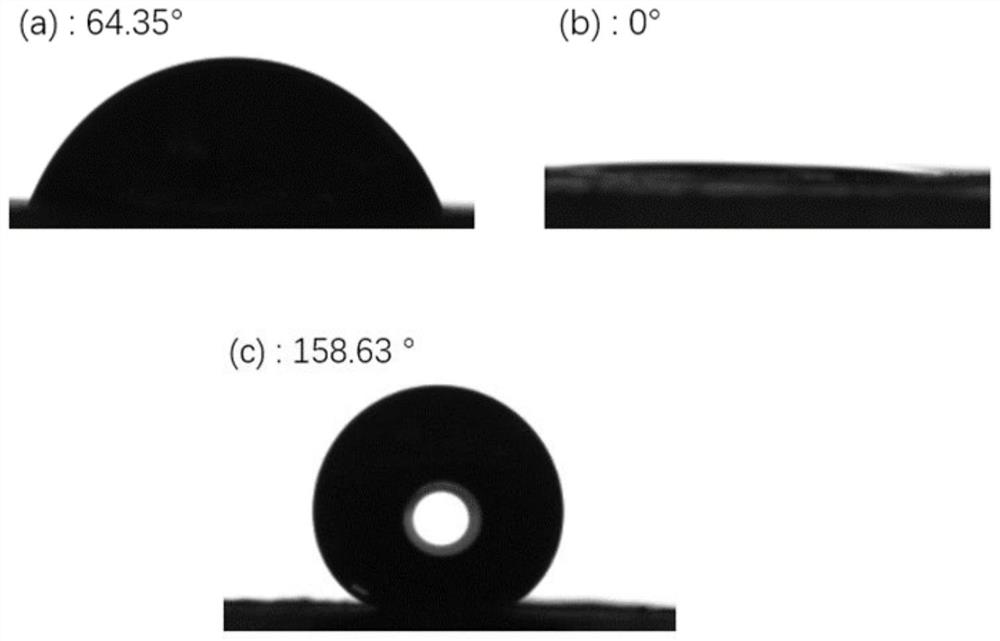

[0039] A kind of Ni-Co / Cu superhydrophobic coating of the present invention, its preparation method comprises steps as follows:

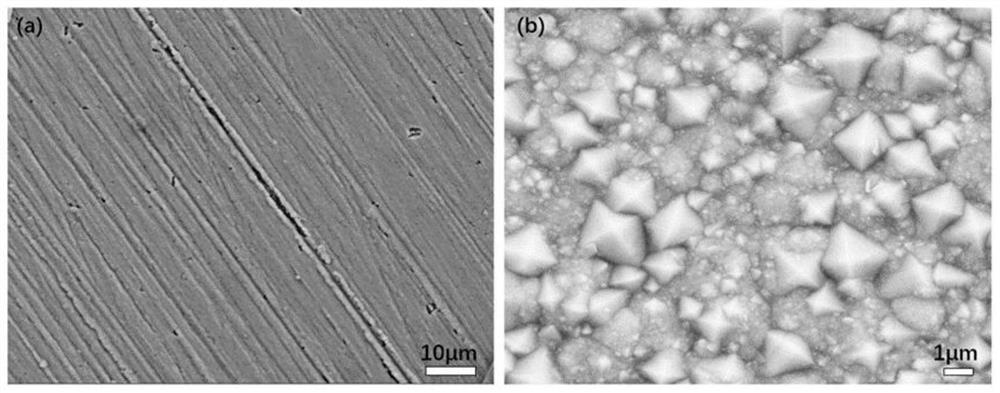

[0040] 1. The base material is Q235 carbon steel, which is cut and encapsulated with epoxy resin so that the working area is 1 cm 2 , the substrate was polished with 2000# sandpaper to remove surface corrosion products, then cleaned with acetone and ethanol, and dried for later use.

[0041] 2. Configuration of Ni-Co plating solution: weigh 20 g NiSO 4 ·6H 2 O, 5 g CoSO 4 ·7H 2 O and 3 g NiCl 2 ·6H 2 O was put into a 200 mL beaker, then 100 mL of deionized water was added, and stirred thoroughly to dissolve. Weigh 3 g H 3 BO 3 , put into a 50 mL beaker, add 25 mL deionized water, heat until boiling, and maintain for 4 min. Finally H 3 BO 3 The solution was slowly added dropwise to the main salt solution.

[0042] 3. Configuration of Cu plating solution: Weigh CuCl 2 2H 2 O 5 g, add 100 mL deionized water, fully stir to dissolve, then w...

Embodiment 2

[0049] A kind of Ni-Co / Cu superhydrophobic coating of the present invention, its preparation method comprises steps as follows:

[0050] 1. The base material is Q255 carbon steel, which is cut and encapsulated with epoxy resin so that the working area is 1 cm2. The base is polished with 2000# sandpaper to remove surface corrosion products, then cleaned with acetone and ethanol, and dried for later use.

[0051] 2. Configuration of Ni-Co plating solution: weigh 10 g NiSO 4 ·6H 2 O, 2 g CoSO 4 ·7H 2 O and 1 g NiCl 2 ·6H 2 O was put into a 200 mL beaker, then 100 mL of deionized water was added, and stirred thoroughly to dissolve. Weigh 1 g H 3 BO 3 , put into a 50 mL beaker, add 25 mL deionized water, heat until boiling, and maintain for 3 min. Finally H 3 BO 3 The solution was slowly added dropwise to the main salt solution.

[0052] 3. Configuration of Cu plating solution: Weigh CuCl 2 2H 2 O 3 g, add 100 mL deionized water, fully stir to dissolve, then weigh 2 g ...

Embodiment 3

[0058] A kind of Ni-Co / Cu superhydrophobic coating of the present invention, its preparation method comprises steps as follows:

[0059] 1. The base material is Q275 carbon steel, which is cut and encapsulated with epoxy resin so that the working area is 1 cm2. The base is polished with 2000# sandpaper to remove surface corrosion products, then cleaned with acetone and ethanol, and dried for later use.

[0060] 2. Configuration of Ni-Co plating solution: weigh 15 g NiSO 4 ·6H 2 O, 4 g CoSO 4 ·7H 2 O and 2 g NiCl 2 ·6H 2 O was put into a 200 mL beaker, then 100 mL of deionized water was added, and stirred thoroughly to dissolve. Weigh 4 g H 3 BO 3 , put into a 50 mL beaker, add 25 mL deionized water, heat until boiling, and maintain for 4 min. Finally H 3 BO 3 The solution was slowly added dropwise to the main salt solution.

[0061] 3. Configuration of Cu plating solution: Weigh CuCl 2 2H 2 O 4 g, add 100 mL deionized water, fully stir to dissolve, then weigh 7g N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com