Sunlight-driven self-repairing coating, coating layer, and preparation method of coating layer

A self-healing, sunlight technology, used in coatings, polyester coatings, polyamide coatings, etc., can solve the problems of strict repair conditions, inability to achieve multiple repairs of coatings, and inability to achieve self-repair, etc., to extend the protection life. , Excellent sunlight-driven self-healing effect, wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1 Solar-driven self-healing coating

[0046] 1. Raw materials

[0047] This implementation provides 7 kinds of self-healing coatings, the composition of which is shown in Table 1.

[0048] Table 1 Raw material composition of different self-healing coatings

[0049]

[0050]

[0051]

[0052] 2. Preparation of coating

[0053](1) The substrate material is 2024 aluminum alloy. The substrate is polished with 2000# sandpaper to remove the corrosion products existing on the surface, then cleaned with acetone and ethanol, and dried for later use.

[0054] (2) Add organic resin, thermoplastic phase change material, and curing agent to a good solvent and ultrasonically dissolve (the power is 75W, and the ultrasonic time is 120min), then add photothermal materials, and stir at 1000rpm / min to fully disperse to obtain a repair coating;

[0055] (3) Spin-coat the repair coating on the surface of the treated base material, wait for 7 days for the solvent to vo...

experiment example 1

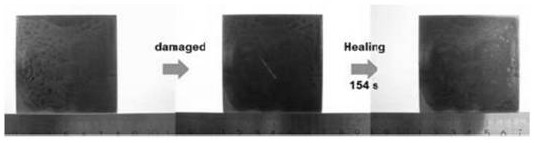

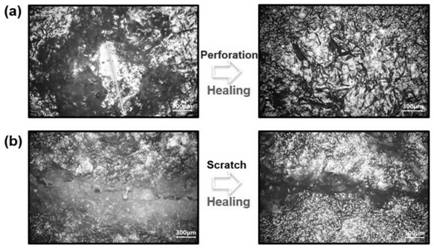

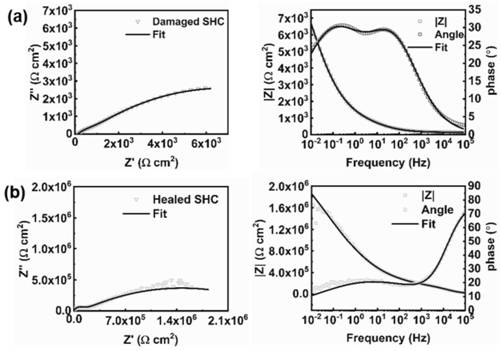

[0072] Taking coating 2 in embodiment 1 as an example, its microstructure, morphology before and after solar repair, electrochemical impedance spectroscopy (EIS) of the coating before and after solar repair are characterized, and the results are shown in Figure 1-3 .

[0073] 1. Experimental method

[0074] (1) Observation of microstructure: The microstructure of the coating was observed by scanning electron microscope (SEM).

[0075] (2) Observation of morphology before and after sunlight repair: use a scalpel to prepare scratches or small hole defects on the surface of the prepared coating, put the defective coating under sunlight between noon and 2 p.m., and observe the surface repair situation. Record the repair of the surface at regular intervals.

[0076] (3) Electrochemical impedance spectroscopy of the coating before and after solar repair: put the repaired sample in 3.5% NaCl medium, and use an electrochemical workstation (Gamry 600) to test the AC impedance spect...

experiment example 2

[0083] The coatings a-c in Comparative Example 1 and the coatings e-f in Comparative Example 2 were scratched with a scalpel on the surface of the prepared coatings, and the coatings with defects were exposed to sunlight between noon and 2 p.m. For 600 s, before and after exposure to sunlight, each sample was placed in a 3.5% NaCl medium, and an electrochemical workstation (Gamry 600) was used to test the AC impedance spectrum of the coating.

[0084] table 5

[0085]

[0086] It can be seen from the results in Table 5 that after the scratch defects of coatings a-f are repaired under sunlight, the impedance modulus values of the coatings are not significantly different from those of the defective coatings with scratches, indicating that the scratched coatings a-f are repaired Complete restoration of the coating cannot be achieved under sunlight exposure.

[0087] It shows that the present invention achieves the best sunlight self-healing effect by reasonably controlling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com