Low-iron-loss automobile engine stator iron core and preparation process thereof

A technology for automobile engines and stator cores, which is applied in the manufacture of motor generators, metal material coating technology, electric components, etc., can solve problems such as power shortage and shortage of oriented silicon steel, and achieve extended service life, strong comprehensive quality, and excellent Effect of low iron loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

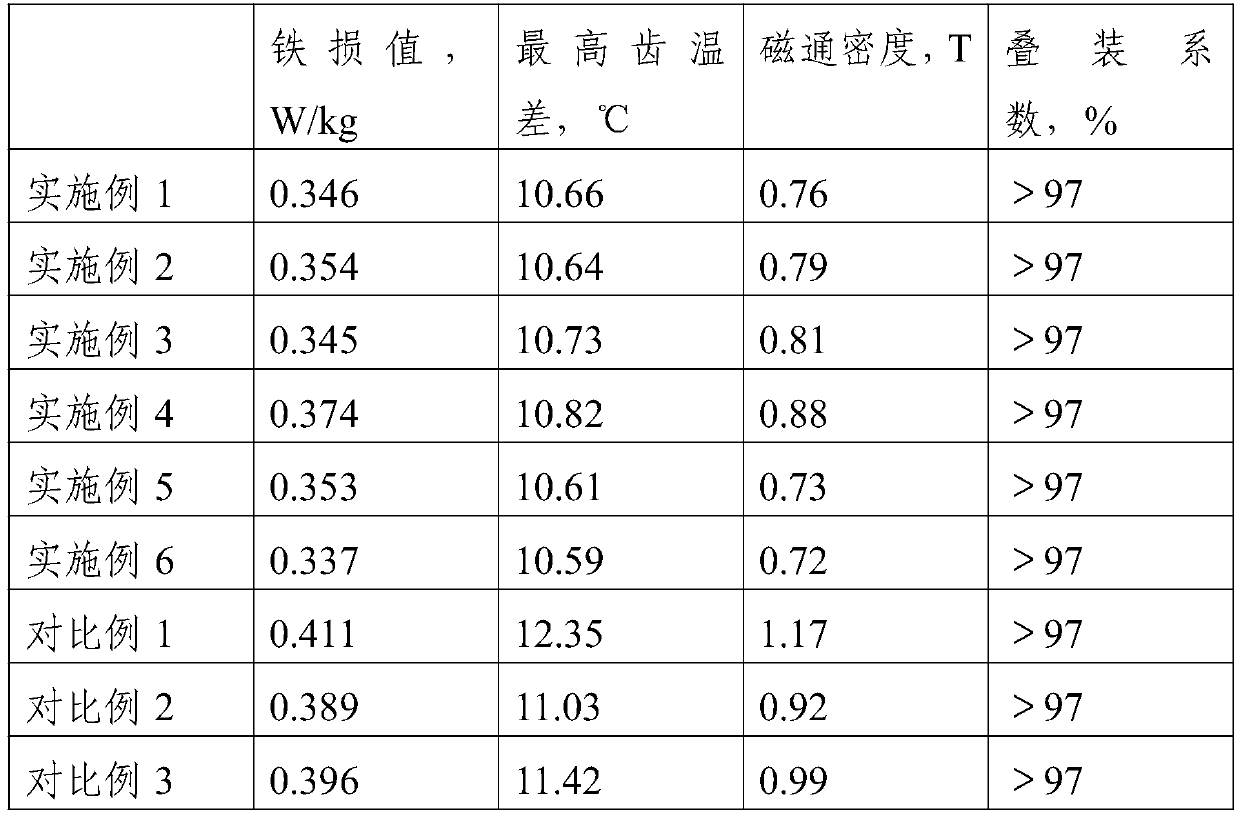

Examples

Embodiment 1

[0024] A low iron loss automobile engine stator iron core, the stator iron core is a multi-layer structure, including a silicon steel sheet body, a loss-reducing outer layer, and a protective paint layer sequentially designed from the inside to the outside, and the silicon steel sheet body is made of rare earth. Borosilicate steel sheet, the thickness of the silicon steel sheet body is 0.28mm; the loss reduction outer layer is a composite alloy material, and the layer thickness is 0.025mm; the protective paint layer is a composite impregnation paint, and the layer thickness is 0.06mm.

[0025] The silicon steel sheet body includes the following components by mass percentage: Si 2.0wt%, RE 0.06%, B 0.1%, P0.1%, Mn 0.22%, Al<0.004%, S<0.004%, C<0.004%.

[0026] The composite alloy material includes iron-cobalt alloy, Fe2Ni alloy, calcium aluminate, copper phosphide, the cobalt content in the iron-cobalt alloy is 48wt%, and 13wt% of the iron source in the iron-containing alloy com...

Embodiment 2

[0030] A low iron loss automobile engine stator core, the stator core is a multi-layer structure, including a silicon steel sheet body, a loss-reducing outer layer, and a protective paint layer designed sequentially from the inside to the outside, and the silicon steel sheet body is made of rare earth Borosilicate steel sheet, the thickness of the silicon steel sheet body is 0.28mm; the loss-reducing outer layer is a composite alloy material with a layer thickness of 0.03mm; the protective paint layer is a compound dipping paint with a layer thickness of 0.04mm.

[0031] The silicon steel sheet body includes the following components in mass percentage: Si 1.8wt%, RE 0.1%, B 0.07%, P0.08%, Mn 0.23%, Al<0.004%, S<0.004%, C<0.004%.

[0032] The composite alloy material includes iron-cobalt alloy, Fe2Ni alloy, calcium aluminate, and copper phosphide. The cobalt content in the iron-cobalt alloy is 48wt%, and 15wt% of the iron source in the iron-containing alloy comes from sponge iro...

Embodiment 3

[0036] A low iron loss automobile engine stator core, the stator core is a multi-layer structure, including a silicon steel sheet body, a loss-reducing outer layer, and a protective paint layer designed sequentially from the inside to the outside, and the silicon steel sheet body is made of rare earth Borosilicate steel sheet, the thickness of the silicon steel sheet body is 0.30mm; the loss-reducing outer layer is a composite alloy material with a layer thickness of 0.04mm; the protective paint layer is a compound dipping paint with a layer thickness of 0.06mm.

[0037] The silicon steel sheet body includes the following components in mass percentage: Si 1.8wt%, RE 0.06%, B 0.06%, P0.08%, Mn 0.23%, Al<0.004%, S<0.004%, C<0.004%.

[0038] The composite alloy material includes iron-cobalt alloy, Fe2Ni alloy, calcium aluminate, and copper phosphide. The cobalt content in the iron-cobalt alloy is 48wt%, and 10wt% of the iron source in the iron-containing alloy comes from sponge ir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Layer thickness | aaaaa | aaaaa |

| Layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com