Titanium and nano fluorine-containing poly (aryl ether ketone) copolymer, coating made thereof and manufacturing method thereof

A technology of polyaryletherketone and titanium nanometers, which is applied in the field of chemical synthesis and chemical composition, which can solve the problem of affecting the normal production of enterprises and accelerating the chemical corrosion of oil and gas downhole drilling tools, pipe strings, pipelines and above-ground oil and gas pipelines, containers and storage tanks and sediment scaling, oil and gas field production costs increase and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

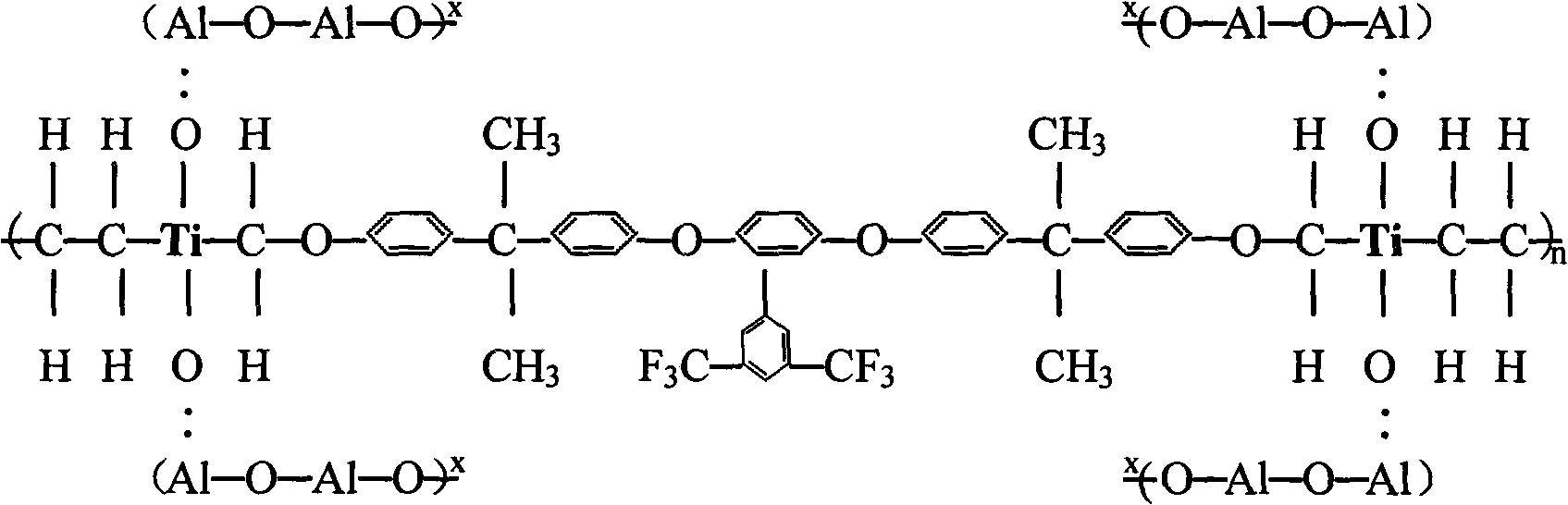

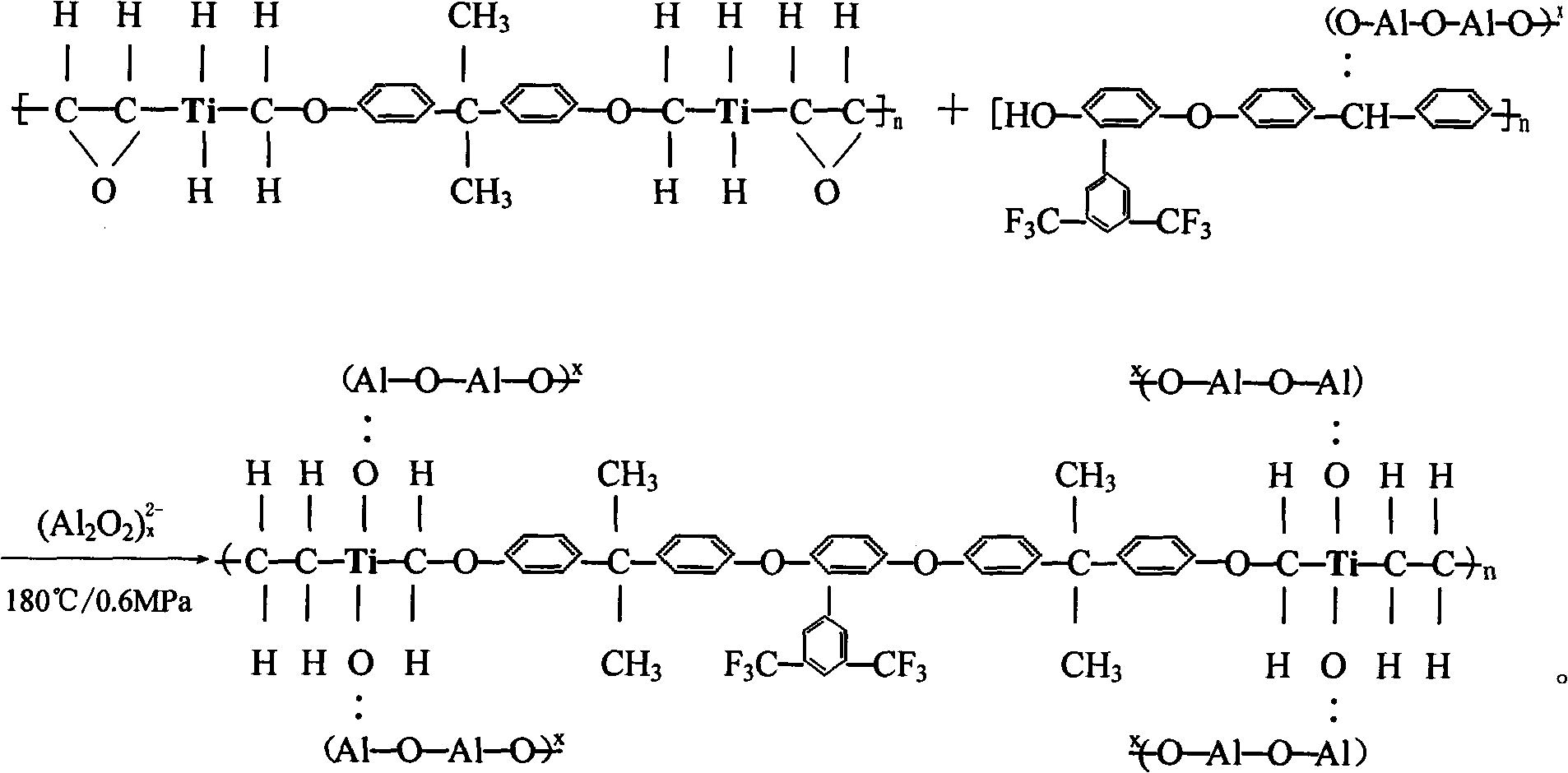

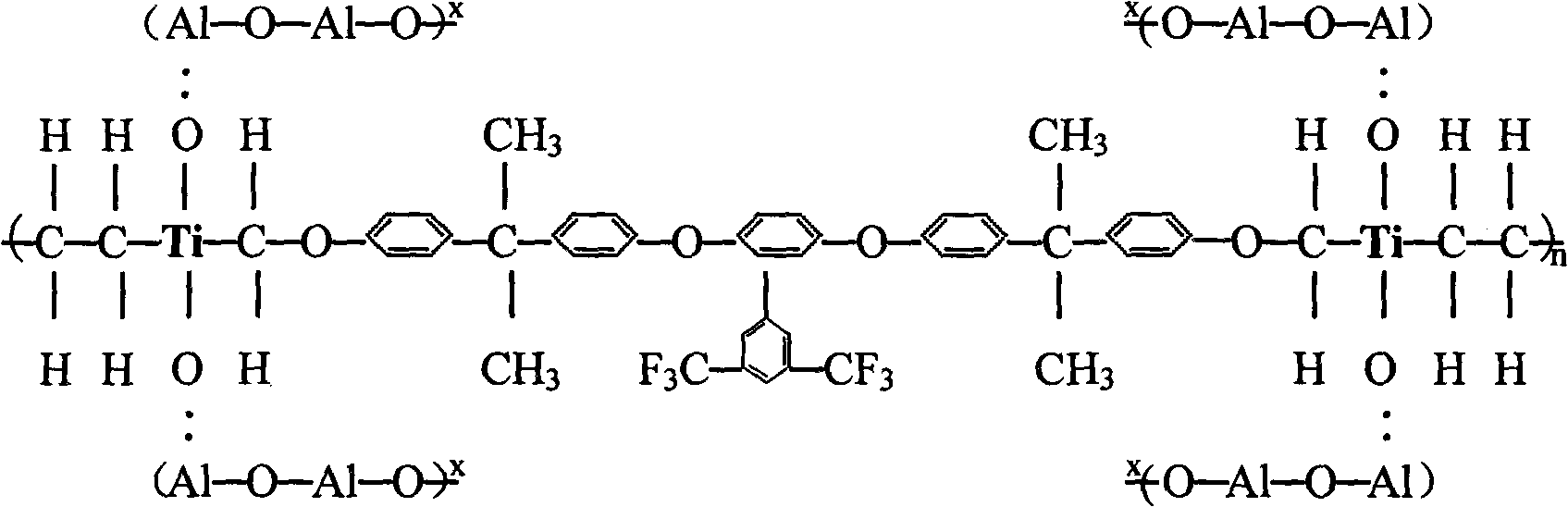

[0020] The preparation method of the titanium nanometer fluorine-containing polyaryl ether ketone copolymer of the present invention comprises the chemical synthesis reaction process as shown in the following reaction formula:

[0021]

[0022] In the formula, the degree of polymerization n≥8; for nano-alumina.

[0023] In order to complete the above chemical synthesis reaction, the specific implementation steps are as follows:

[0024] The first step The equipment and raw materials required for the preparation of titanium nanometer fluorine-containing polyaryletherketone copolymers are listed as follows:

[0025] 1. Main equipment: ①QM-1SP4 closed planetary ball mill reactor; ②LBM-T1 frequency conversion high-speed dispersing machine; ③LBM-T2 frequency conversion basket sand mill.

[0026] 2. Main raw materials: ①Basic raw materials: nano-organic titanium polymer (HTH); nano-alumina modified fluorine-containing polyaryletherketone polymer [(PAEK_F-Al 2 o 3 ) n x ]. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com