Silane waterproof material for concrete protection and preparation method thereof

A waterproof material and concrete technology, applied in the direction of coating, etc., can solve the problems of low surface energy interface wettability, insufficient durability, high volatilization rate, etc., and achieve the effects of long protection life, low construction difficulty coefficient and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

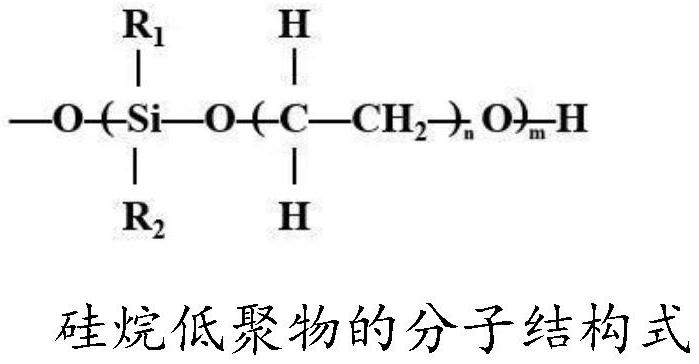

Method used

Image

Examples

Embodiment 1

[0029] Decyltriethoxysilane, silane oligomer, γ-aminopropyltrimethoxysilane, polyoxypropylene glyceryl ether defoamer, antioxidant (phenol hindered phenolic antioxidant 1010 and phosphite according to mass ratio 1:1 composite) and nitrite preservatives are weighed according to the mass ratio of 60:32:8:0.1:0.1:0.2. First, pour decyltriethoxysilane, silane oligomers and γ-aminopropyltriethoxysilane into a stirring container, mix and stir in an electric mixer, and then pour the mixture of defoamer, antioxidant and preservative Add and continue to stir to obtain a silane waterproof material.

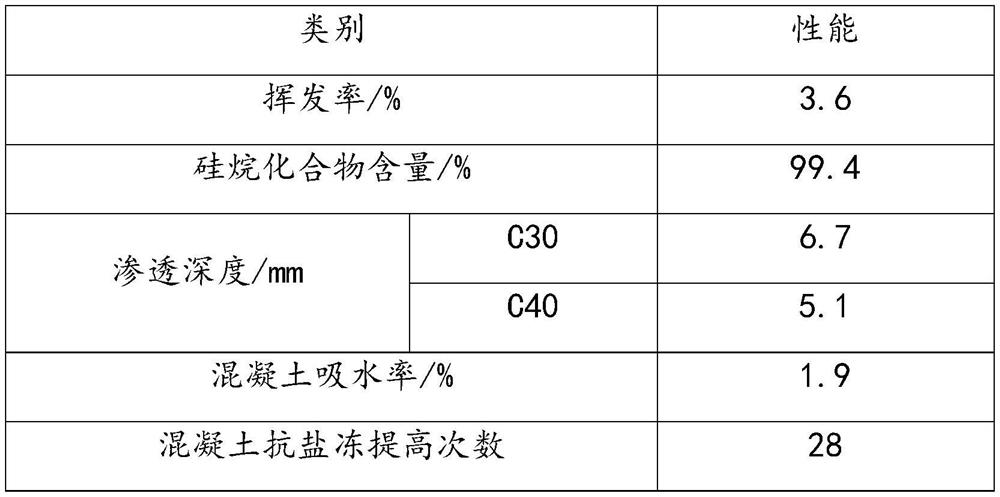

[0030] The properties of specific silane waterproof materials are as follows:

[0031]

[0032]

Embodiment 2

[0034] Dodecyltriethoxysilane, silane oligomer, γ-aminopropyltriethoxysilane, polyoxyethylene polyoxypropylene pentaerythritol ether defoamer, antioxidant (phenol hindered phenolic antioxidant 1010 and The phosphite is compounded according to the mass ratio of 1:1), and the nitrite preservative is weighed according to the mass ratio of 60:30:10:0.1:0.1:0.2. First, pour dodecyltriethoxysilane, silane oligomers and γ-aminopropyltriethoxysilane into a stirring container, mix and stir in an electric mixer, and then add defoamer, antioxidant and preservative The mixture is poured into and continuously stirred to obtain a silane waterproof material.

[0035] The properties of specific silane waterproof materials are as follows:

[0036]

Embodiment 3

[0038] Hexadecyltriethoxysilane, silane oligomer, γ-aminopropyltrimethoxysilane, polyoxyethylene polyoxypropylene pentaerythritol ether defoamer, antioxidant (phenol hindered phenolic antioxidant 1010 and sub The phosphate ester is compounded according to the mass ratio of 1:1) and the modified silicone emulsion preservative is weighed according to the mass ratio of 70:20:10:0.1:0.1:0.2. First pour dodecyltriethoxysilane, silane oligomers and γ-aminopropyltrimethoxysilane into the mixing container, mix and stir in an electric mixer, and then add the defoamer, antioxidant and preservative mixture Pour in and continue to stir to obtain a silane waterproof material.

[0039] The properties of specific silane waterproof materials are as follows:

[0040]

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration depth | aaaaa | aaaaa |

| penetration depth | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com