Nickel alloy composition modulated multilayer alloy (CMMA) coating and preparation method thereof

A nickel alloy and coating technology, which is applied in the field of nickel alloy CMMA coating and its preparation, can solve the problems of low corrosion resistance, and achieve the effects of improving corrosion resistance, improving operability, and improving hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Take 250g of nickel sulfate, 2g of trimethylamine borane, 60g of boric acid, 4g of SiC with a particle size of 1 μm, 1g of saccharin and 0.01g of sodium lauryl sulfate, prepare 1 liter of electrolyte with deionized water, and use sodium hydroxide solution Adjust its pH value to 3.5, use a water bath to control the temperature at 45°C, mechanically stir for 1 hour, and ultrasonically disperse for 30 minutes.

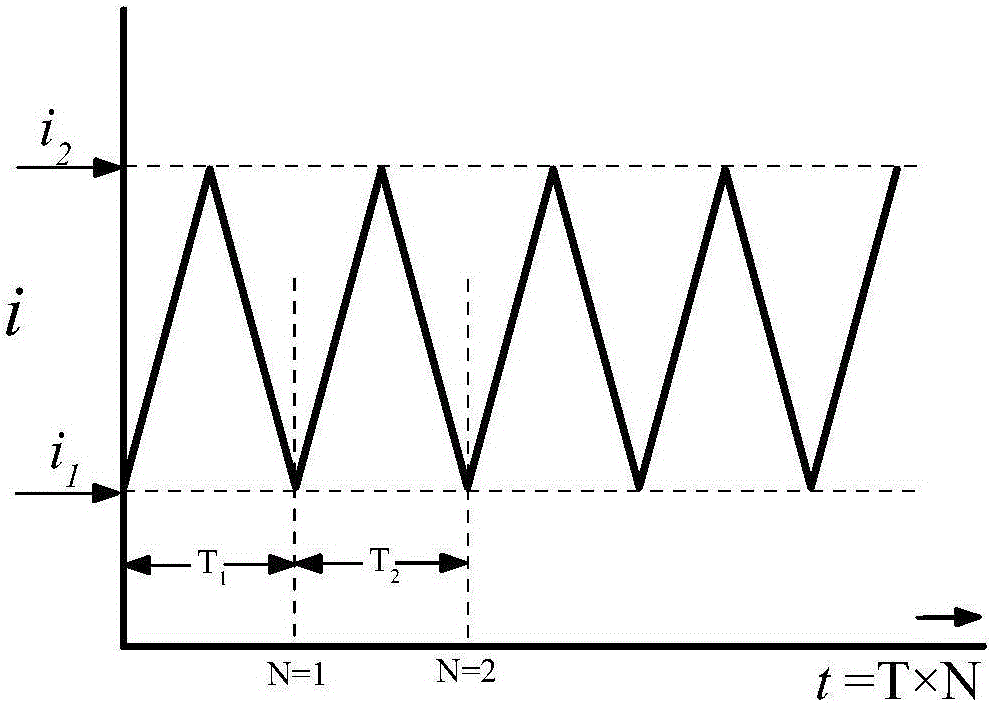

[0033] set up i 1 =1A / dm 2 , i 2 =4A / dm 2 , T=2s, N=500, graphite as anode, Q235 steel as cathode, current density at i 1 , i 2 between continuous linear changes, such as figure 1 As shown, the deposition of Ni-B / SiC 1.0 / 4.0 / 50 0 , where the subscript 1.0 represents i 1 =1A / dm 2 , the subscript 4.0 represents i 2 =4A / dm 2 , the subscript 500 represents the total number of coating layers is 500.

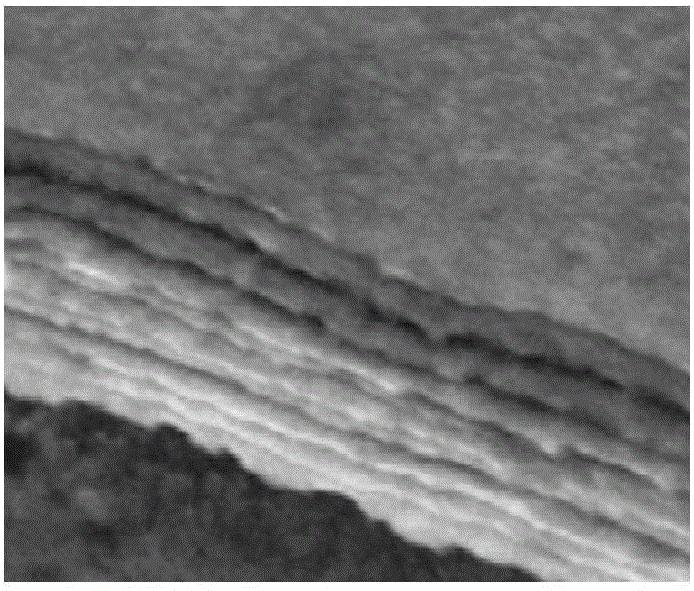

[0034] Ni-B / SiC obtained by the above method 1.0 / 4.0 / 500 Coating, the total number of coating layers is 500, and the total thickness is about 66 μm. The...

Embodiment 2

[0036] Take 150g of nickel sulfate, 120g of nickel chloride, 6g of trimethylamine borane, 30% of boric acid, 5g of SiC with a particle size of 1 μm, 2g of saccharin, and 0.4g of AES, and prepare 1 liter of electrolyte solution with deionized water, using sodium hydroxide solution Adjust its pH value to 4.0, use a water bath to control the temperature at 60°C, mechanically stir for 1 hour, and ultrasonically disperse for 15 minutes.

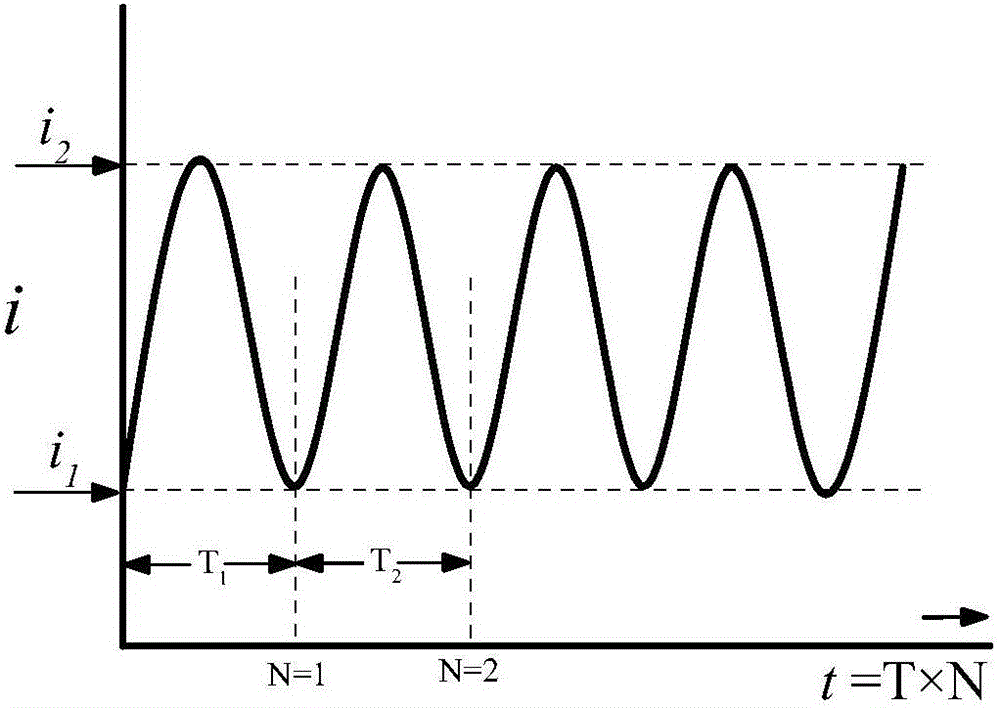

[0037] set up i 1 =1.0A / dm 2 , i 2 =5A / dm 2 , T=4s, N=250, nickel plate as anode, Q235 steel as cathode, current density at i 1 , i 2 between continuous nonlinear changes, such as figure 2 As shown, the deposition of Ni-B / SiC 1.0 / 5.0 / 250 , where the subscript 1.0 represents i 1 =1.0A / dm 2 , the subscript 5.0 represents i 2 =5.0A / dm 2 , the subscript 250 represents the total number of layers of the coating is 250.

[0038] Ni-B / SiC obtained by the above method 1.0 / 5.0 / 250 Coating, the total number of coating layers is 250, and t...

Embodiment 3

[0040] Take 150g of nickel sulfate, 50g of nickel chloride, 120g of sodium tungstate, 12g of sulfamic acid, and TiO with a particle size of 1 μm 2 15g, ammonium chloride 65g, AES 0.4g, use deionized water to prepare 1 liter of electrolyte solution, use sodium hydroxide solution to adjust its pH value to 7.0, use a water bath to control the temperature at 70 ° C, mechanically stir for 1 hour, ultrasonic Disperse for 15 minutes.

[0041] set up i 1 =1.0A / dm 2 , i 2 =5A / dm 2 , T=4s, N=250, nickel plate as anode, Q235 steel as cathode, current density at i 1 i 2 Continuous linear change between, and deposition of Ni-W / TiO 21.0 / 5.0 / 250 , where the subscript 1.0 represents i 1 =1.0A / dm 2 , the subscript 5.0 represents i 2 =5.0A / dm 2 , the subscript 250 represents the total number of layers of the coating is 250.

[0042] Ni-W / TiO obtained by the above method 21.0 / 5.0 / 250 Coating, the total number of coating layers is 250, the total thickness is about 94 μm, the mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com