Leading edge protecting layer technology for fan blades

A technology for the leading edge of the blade and the fan blade, which is used in coatings, layered products, synthetic resin layered products, etc., which can solve the problems of inconvenient re-filming, the protection film scheme is not widely used, and the degree of paint damage cannot be judged in time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

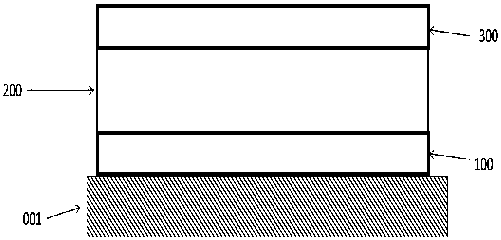

[0042] see figure 1 In this embodiment, 30-100 micron polyacrylic pressure-sensitive adhesive is used as the adhesive layer 100 to be placed on the upper surface of the conventional coating 001 of the fan blade, and 0.5-1% of UV absorber is added to the adhesive layer 100 .

[0043] The protective film layer 200 is placed on the upper surface of the adhesive layer 100, and the protective film layer 200 is made of a transparent single-layer thermoplastic polyurethane material TPU with a thickness of 200-400 microns.

[0044] The paint layer 300 adopts water-based two-component polyurethane paint with a thickness of 100-300 microns.

Embodiment 2

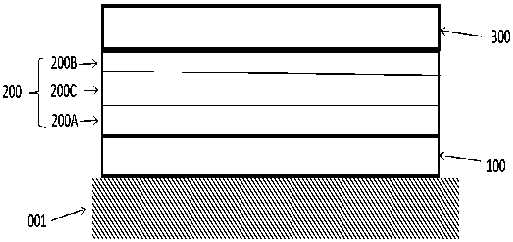

[0046] see figure 2 In this embodiment, a 30-100 micron acrylic pressure-sensitive adhesive is used as the adhesive layer 100 to be placed on the upper surface of the conventional coating 001 of the fan blade, and 0.5-1% of UV absorber is added to the adhesive layer 100 .

[0047] The protective film layer 200 is placed on the upper surface of the adhesive layer 100. The protective film layer 200 is composed of two layers of thermoplastic polyurethane material TPU (the first layer 200A and the second layer 200B), and the thicknesses are 100-300 microns respectively. Acrylic pressure-sensitive 200C with a thickness of 50-100 microns is used as an adhesive layer between two layers of thermoplastic polyurethane material TPU. The three-layer structure together constitutes the protective film layer 200 .

[0048] The paint layer 300 adopts water-based two-component polyurethane paint with a thickness of 100-300 microns.

Embodiment 3

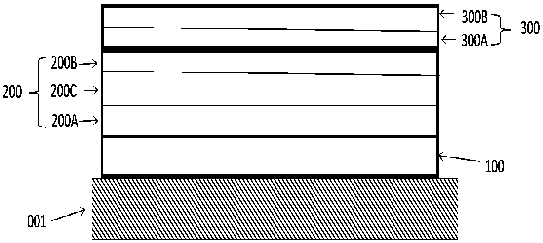

[0050] see image 3 In this embodiment, a 30-100 micron acrylic pressure-sensitive adhesive is used as the adhesive layer 100 to be placed on the upper surface of the conventional coating 001 of the fan blade, and 0.5-1% of UV absorber is added to the adhesive layer 100 .

[0051] The protective film layer 200 is placed on the upper surface of the adhesive layer 100. The protective film layer 200 is composed of two layers of thermoplastic polyurethane material TPU (the first layer 200A and the second layer 200B), and the thicknesses are 100-300 microns respectively. Acrylic pressure-sensitive 200C with a thickness of 50-100 microns is used as an adhesive layer between two layers of thermoplastic polyurethane material TPU. The three-layer structure together constitutes the protective film layer 200 .

[0052] The paint layer 300 adopts double-layer water-based two-component polyurethane paint, and the first layer 300A has a thickness of 50-100 microns and is red. The second lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com