Paint prefabricated film, protection structure and preparation method of protection structure

A protective structure and prefabricated membrane technology, applied in chemical instruments and methods, mechanical equipment, and other household appliances, can solve the problems of uncontrollable thickness and quality of protective methods, reduce the possibility of stripping, ensure protective effects, and moisturize good wet performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

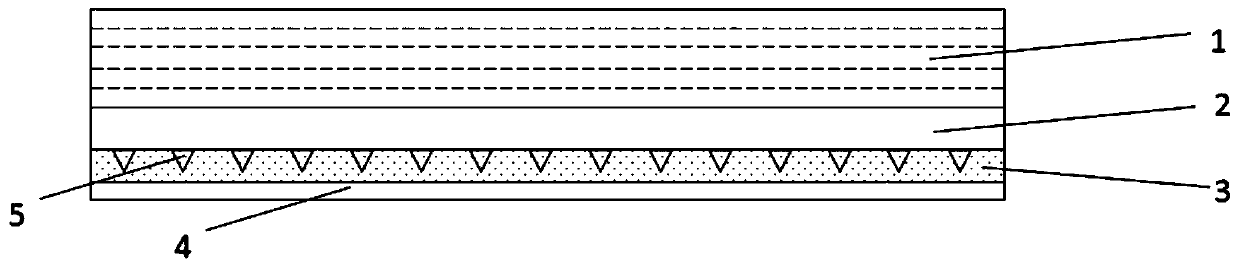

[0054] Such as figure 1 As shown, the present embodiment provides a paint prefabricated film, including a paint prefabricated film substrate and a paint coating 1, and the paint prefabricated film substrate includes a stacked substrate layer 2, a back adhesive layer 3 and a release paper 4, wherein The surface of the base material layer 2 away from the adhesive layer 3 is a smooth plane, the paint coating 1 is arranged on the smooth plane, and the surface of the base material layer 2 facing the adhesive layer 3 is provided with several protrusions 5 .

[0055] The above-mentioned paint prefabricated film, because the surface of the base substrate layer 2 away from the adhesive layer 3 is a smooth plane, the smooth plane has a smaller surface tension, so the wettability is better, thereby forming a paint coating on the smooth surface 1 can make the thickness of the paint coating 1 more uniform, and there are fewer internal defects, so the quality is higher; at the same time, th...

Embodiment 2

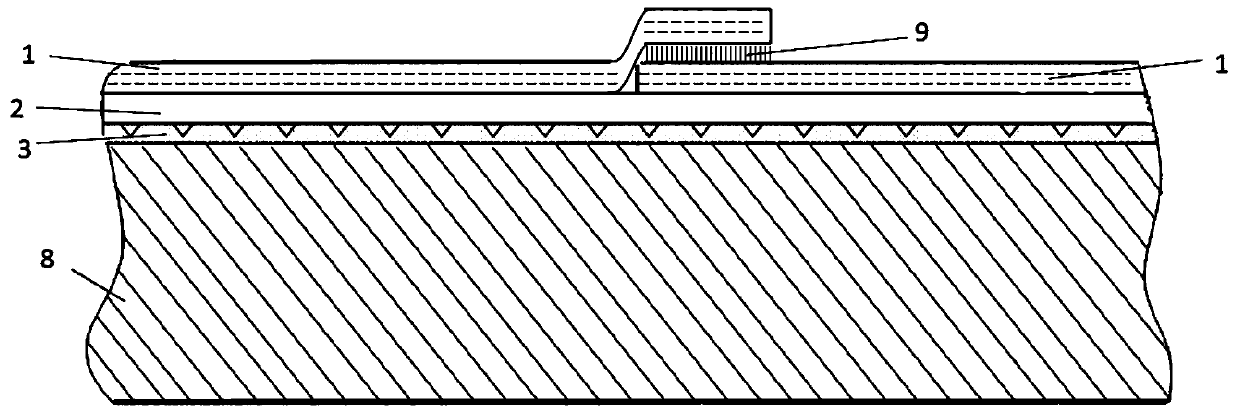

[0065] The present embodiment provides a kind of protective structure, uses the paint prefabricated film that embodiment 1 provides, and its preparation method comprises the following steps:

[0066] (1) The release paper 4 of the paint prefabricated film is torn off, and some paint prefabricated films are pasted on the inner surface of the protective structure mold by the adhesive layer 3;

[0067] (2) forming the first fiber material layer on the paint prefabricated film;

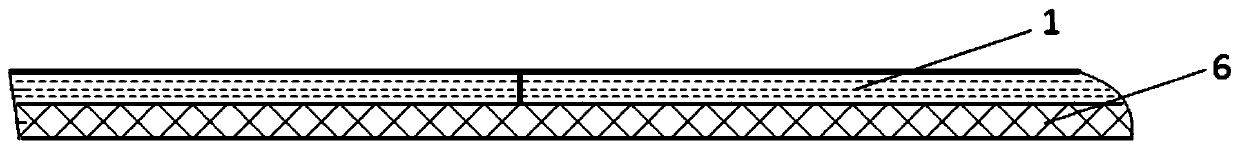

[0068] (3) Under vacuum conditions, form a first resin material in the first fiber material layer and solidify it to obtain the first fiber reinforcement material layer 6;

[0069] (4) After the first resin material is cured, the paint coating 1 is physically separated from the substrate layer 2 under the action of an external force to obtain a protective structure.

[0070] In the preparation method of the above-mentioned protective structure, under vacuum conditions, the air present at the interface be...

Embodiment 3

[0096] This embodiment provides a method for preparing a protective structure, using the paint prefabricated film provided in Example 1, comprising the following steps:

[0097] (1) tear off the release paper 4 of the paint prefabricated film, and paste some paint prefabricated films on the inner surface of the protective structure mold (the inner surface of the protective structure mold is the same shape as the inner surface of the wind power blade mould) by the adhesive layer 3, wherein , 250mm away from the front edge 81 of the protective structure mold and the edge 82 of the protective structure mold, no paint prefabricated film is pasted, and adjacent paint prefabricated films are butted;

[0098] (2) Lay glass fibers on the paint coating 1, the fiber form is a chopped fiber mat, and when the vacuum degree is 40mbar, deposit in the glass fibers and at the interface between the glass fibers and the release cloth by a vacuum infusion molding process epoxy resin, and it is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com