Anti-icing coating for wind turbine blade, and preparation method of anti-icing coating

A fan blade and anti-icing technology, applied in the direction of coating, etc., can solve the problems of endangering personal safety, aging, and increasing the load of the unit, and achieve the effects of excellent comprehensive performance, outstanding low temperature resistance, and good protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

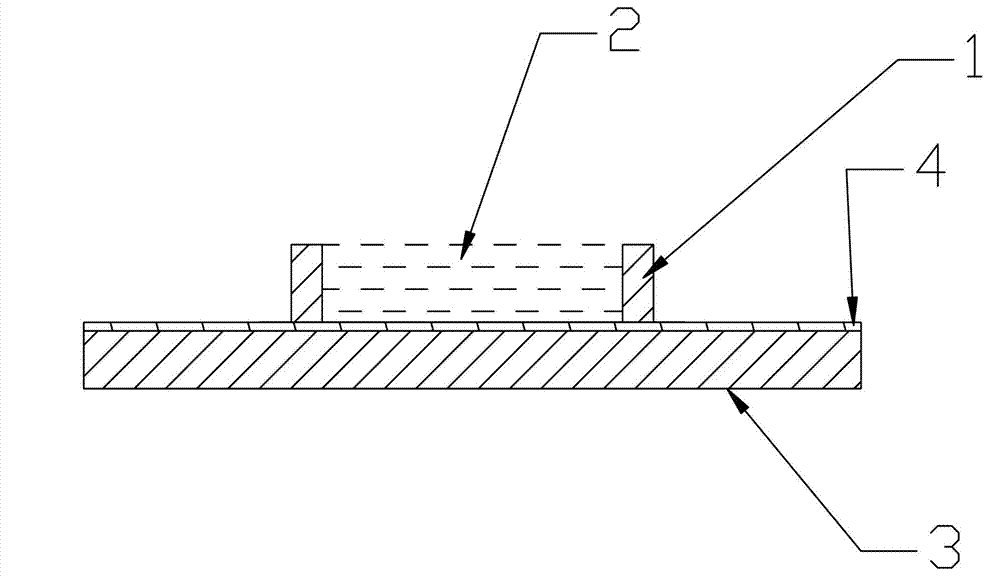

Image

Examples

Embodiment Construction

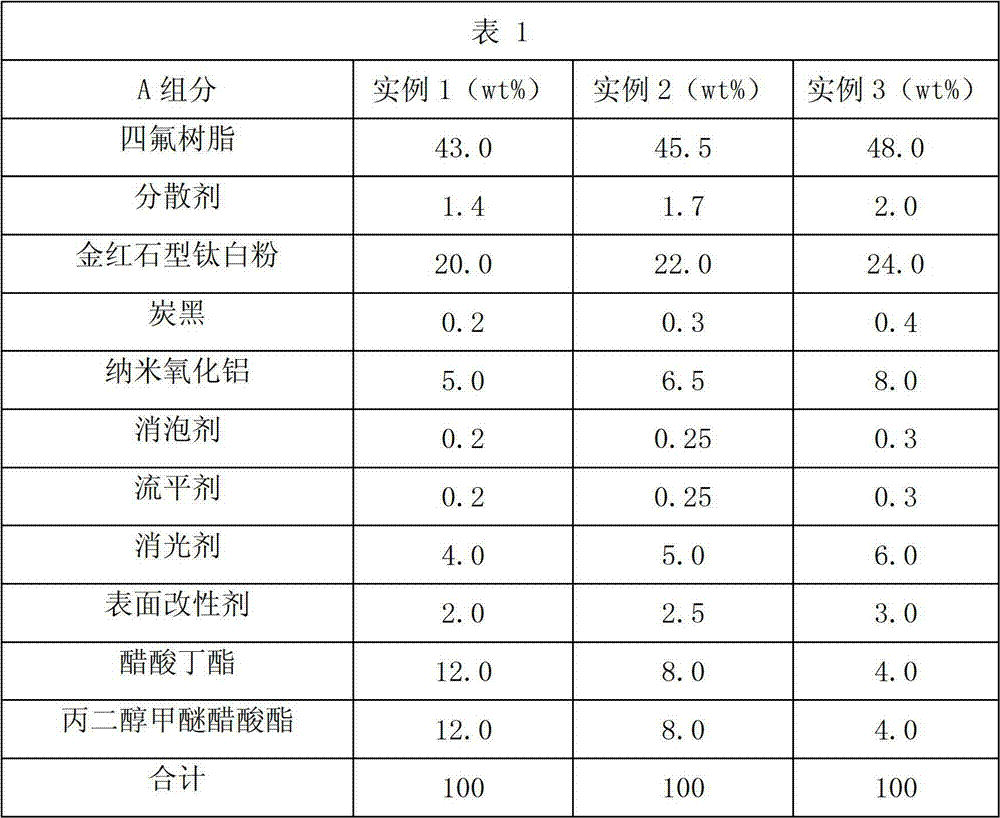

[0024] The A component formula of fan blade anti-icing coating in embodiment 1 to embodiment 3 is as shown in table 1:

[0025]

[0026] The B component of the anti-icing coating for fan blades in Examples 1 to 3 is HDI trimer.

[0027] The tetrafluororesin is fluorocarbon resin GK570 from DAIKIN, Japan, the HDI trimer is N3390 from Bayer, Germany, and the dispersant is BYK- 161, the rutile titanium dioxide is TS-6200 (DuPont), the carbon black is the MA-100 of Mitsubishi, and the defoamer is BYK-051 of the German BYK company, and the flow The leveling agent is BYK-354 of BYK Company of Germany, the matting agent is OK412 of Degussa Company of Germany, and the surface modifier is BYK-3700 of BYK Company of Germany.

[0028] The mass ratio of component A and component B of the anti-icing coating for fan blades in Examples 1 to 3 is 1.5:1, that is, if the component A is 1.5 kg, the component B is 1 kg.

[0029] The preparation method of fan blade anti-icing coating in embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com