Nano micrometer modefied wear resistant erosion resistant thermal coated tubular wire

A tubular wire, erosion-resistant technology, applied in coating, fusion spraying, metal material coating process, etc., can solve the problems of easy brittle fracture, peeling, brittleness, unable to resist stress, etc., and achieve flying speed. Fast, powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

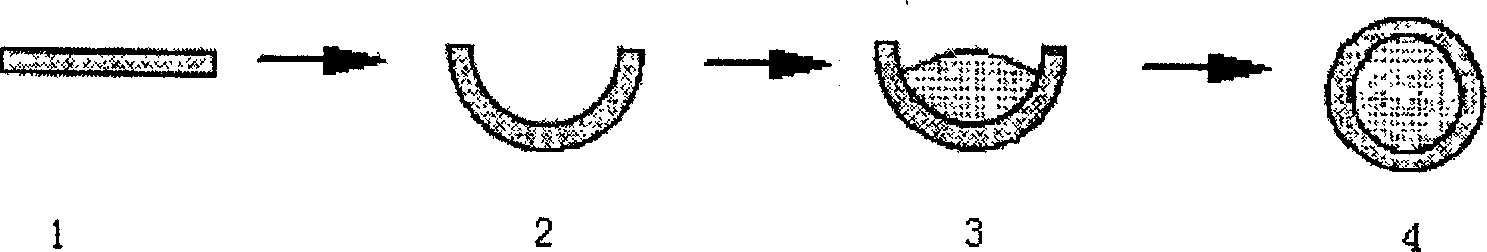

[0024] All the tubular wires of the embodiments are produced by the "FCWM50 core wire drawing machine" manufactured by Kunming Heavy Machinery Factory: the selected width is 8-14mm, and the thickness is 0.25-0.5mm high-quality carbon steel strip or nickel-chromium strip. First roll it into a U shape, and then add mixed medicinal powder with a particle size of 40-200 mesh sieves into the U-shaped groove. The filling rate of the medicinal powder (the percentage of the weight of the medicinal powder in the total weight of the welding wire) is 30-35%. Close the U-shaped groove so that the powder is wrapped in it.

[0025] The base material is No. 20 steel. Before spraying, all the base materials are cleaned with acetone with a mass percentage concentration of 99.8%. The particle size is 25 mesh corundum sand and then arc sprayed. The sandblasting pressure is 0.65MPa. The spraying equipment is JZY type arc spraying Machine, spraying process parameters are shown in Table 1.

[0026...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com