Metal anticorrosion coating and electric arc spraying process thereof

A metal anti-corrosion and coating technology, which is applied in the direction of metal material coating technology, anti-corrosion coatings, metal layered products, etc., can solve the problems that cannot meet the requirements, and achieve the effect of increasing adhesion and enhancing the effective anti-corrosion period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with specific embodiment, further illustrate the present invention.

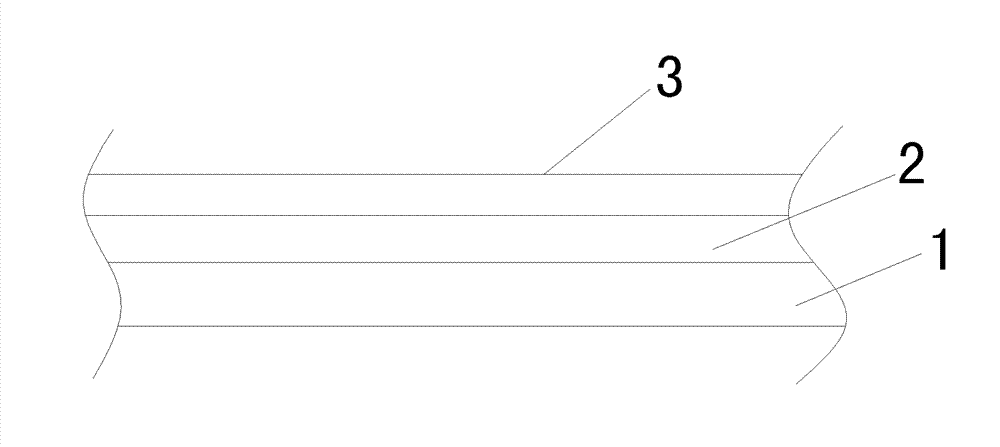

[0017] see figure 1 , the metal anticorrosion coating of the present invention comprises zinc-aluminum alloy bottom layer 1, pure aluminum metal middle layer 2 and sealing paint surface layer 3, the thickness of zinc-aluminum alloy bottom layer 1 is 100um, the thickness of pure aluminum metal middle layer 2 is 80-100um, The thickness of the sealing paint surface layer 3 is 70-90um; wherein the sealing paint is a fluorocarbon topcoat.

[0018] In the zinc-aluminum alloy bottom layer in the present invention, the weight percentage of the zinc-aluminum component is controlled at 6-8:2-4. The fluorocarbon topcoat is prepared by mixing 1 part by weight of curing agent and 10-30 parts by weight of paint; the curing agent is HDI trimer isocyanurate; the weight percentage formula of the paint is: fluorocarbon Resin 40~70, mixed organic solvent 1~30, wax liquid 1~8, aluminum oxide 1~7, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com