Nickle-base corrosion-resisting electric-arc spraying powdered core-wire material

An arc spraying and powder core wire technology, which is applied in coating, melt spraying, metal material coating process and other directions, can solve the ion pitting corrosion of equipment and pipeline salt solution, nickel-based arc spraying powder core wire is not seen Issues such as patents and literature reports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] All the sprayed wires of the embodiments are made by the "FCWM50 passive drawing type flux-cored welding wire machine" manufactured by Kunming Heavy Machinery Factory:

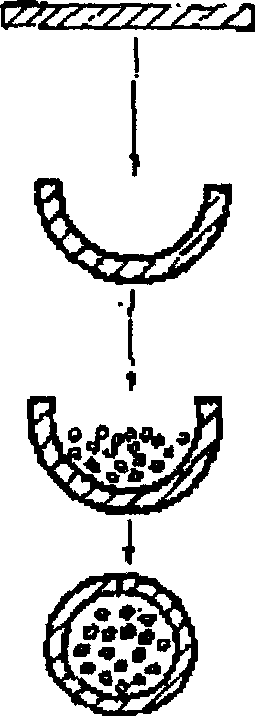

[0018] 1. Select 10×0.4 (width 10mm, thickness 0.4mm) nickel-chromium strip (Ni80+Cr20). Roll it into a U shape first. Get 0.025 kg of metallic nickel powder, 0.14 kg of metallic chromium powder, and 0.335 kg of chromium-boron powder. (The particle size of the powder taken is that it can pass through a 40-mesh sieve). Put the various powders taken into the powder mixer and mix them for 10 minutes, then add the mixed powders into the U-shaped nickel-chromium belt groove, and the filling rate is 25%. Close the U-shaped groove so that the powder is wrapped in it. Then make it pass through the drawing dies with diameters of: 3.0mm, 2.8mm, 2.6mm, 2.5mm, 2.4mm, 2.3mm, 2.2mm, 2.1mm, 2.0mm, 1.9mm, 1.8mm, 1.7mm, 1.6mm, Drawing and reducing the diameter step by step, and finally make the diameter reach 1.6mm....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com