Surface passivation composite cementation layer treatment for concrete bridge affiliate steel structural component and co-cementation agent adopted therein

A technology for steel structure parts and surface treatment, applied in the plating of superimposed layers, metal material coating process, coating and other directions, can solve the problems of decreased anti-corrosion performance, unstable performance, and single anti-corrosion performance.

Active Publication Date: 2018-01-09

METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI

View PDF2 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in fact, since the zinc and aluminum in the protective layer prepared by this process are only in a pseudo-alloy state, its an

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

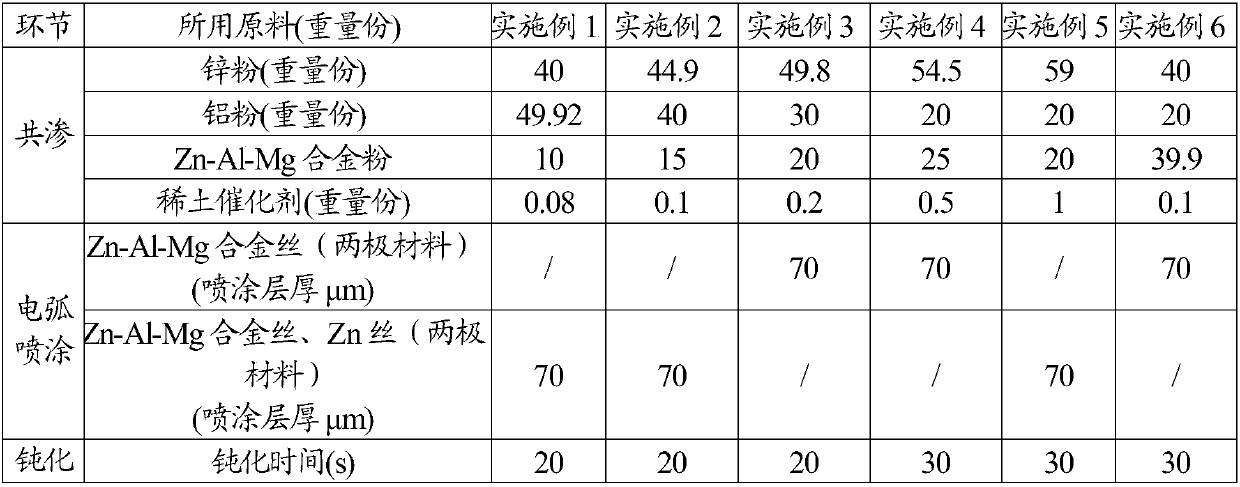

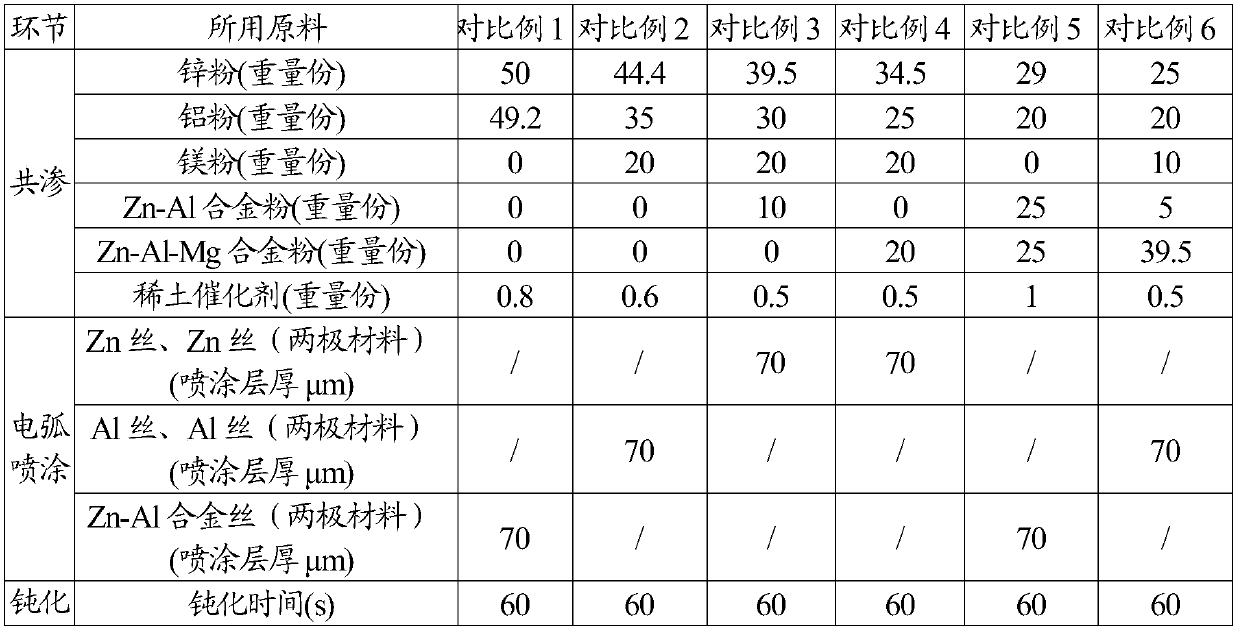

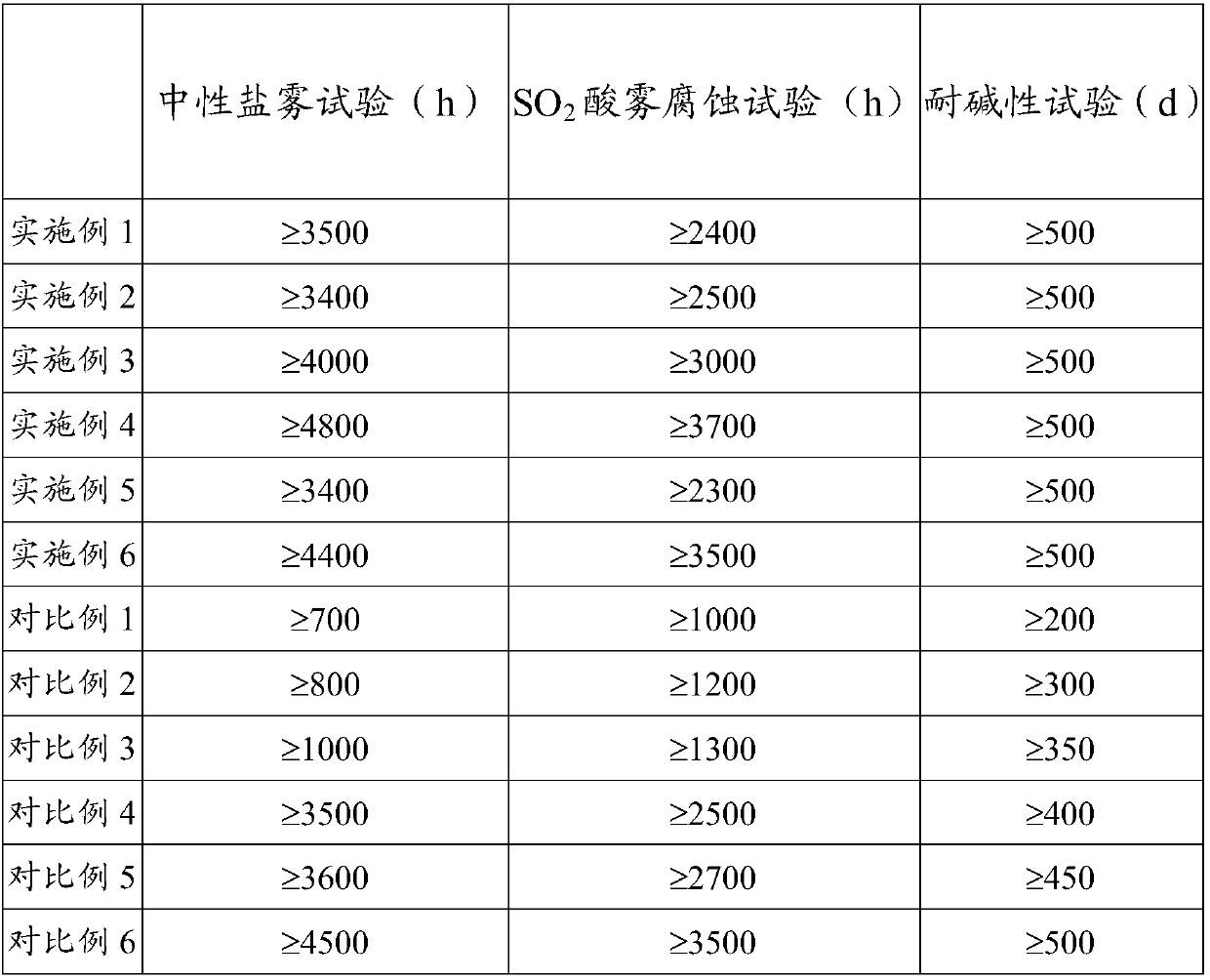

The invention provides surface passivation composite cementation layer treatment for a concrete bridge affiliate steel structural component and a co-cementation agent adopted therein. The co-cementation agent comprises the following components in parts by weight: 40-60 parts of zinc powder, 20-50 parts of aluminum powder, 10-40 parts of Zn-Al-Mg alloy powder and 0.05-2 parts of a rare earth catalyst. According to the method disclosed by the invention, a multicomponent alloy cementation layer is formed on the surface of the steel structural component by the co-cementation layer, and then the co-cemented steel structural component is welded according to a design drawing; electric arc spraying is adopted at a welding joint part, so that a multicomponent alloy layer is formed; and then a passivation agent is used for performing surface passivation sealing treatment on the welded component, so that the novel passivation composite cementation layer (PCA) is formed (steel plate multicomponentalloy co-cementation plus welding joint part electric arc spraying plus passivation treatment with the heavy-metal-element-free passivation agent). The concrete bridge affiliate steel structural component which is obtained through treatment in the invention has good corrosion-resistance and prominent wear-resistance, so that safety and quality are ensured.

Description

technical field [0001] The invention belongs to the technical field of chemical heat treatment and anticorrosion on the surface of metal materials. More specifically, the invention relates to a co-infiltration agent for forming a multi-element alloy infiltration layer on the surface of a steel component and using it to carry out the treatment on the auxiliary steel structure of a concrete bridge. The method of surface treatment. Background technique [0002] In the anti-corrosion treatment of the auxiliary brackets of railway bridges in my country, especially the steel brackets with railings or pedestrian walks on both sides of concrete bridges, on-site paint coating is generally used for anti-corrosion. However, in actual use, repainting and maintenance are required every year, and the cost is relatively high. Especially after the opening to traffic, it is difficult to carry out on-site painting and maintenance operations on a large scale; in addition, as environmental prot...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C23C10/52C23C4/08C23C4/131C23C28/00B22F9/08

Inventor 王涛杜存山祝和权

Owner METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com