Special robot of die for rapid manufacture of covering piece for automobile by metal arc-spraying

A technology for automotive panels and metal arcs, applied in the direction of manufacturing tools, program-controlled manipulators, manipulators, etc., can solve problems such as inability to guarantee mold quality, low deposition speed, unbearable manual operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and the embodiments completed by the inventor.

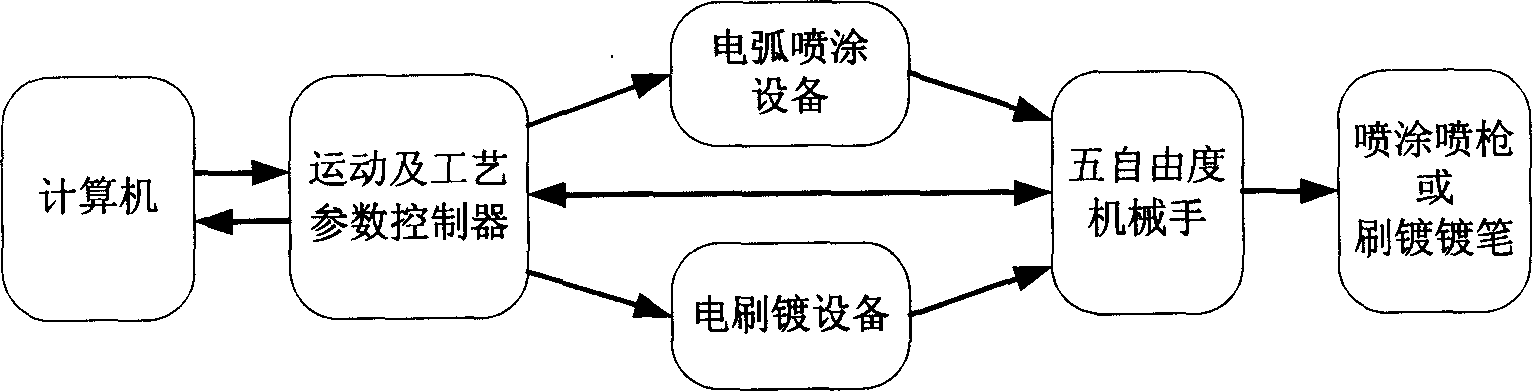

[0026] The invention integrates the two processes of arc spraying and electric brush plating into one device, organically combines the two processes, and realizes the complementary advantages of the two processes.

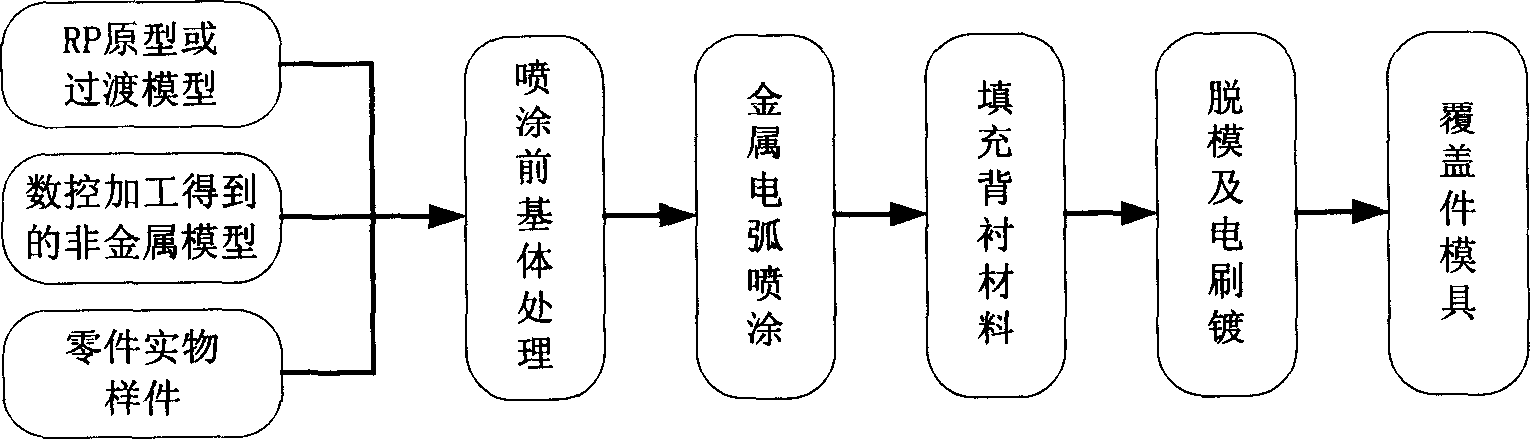

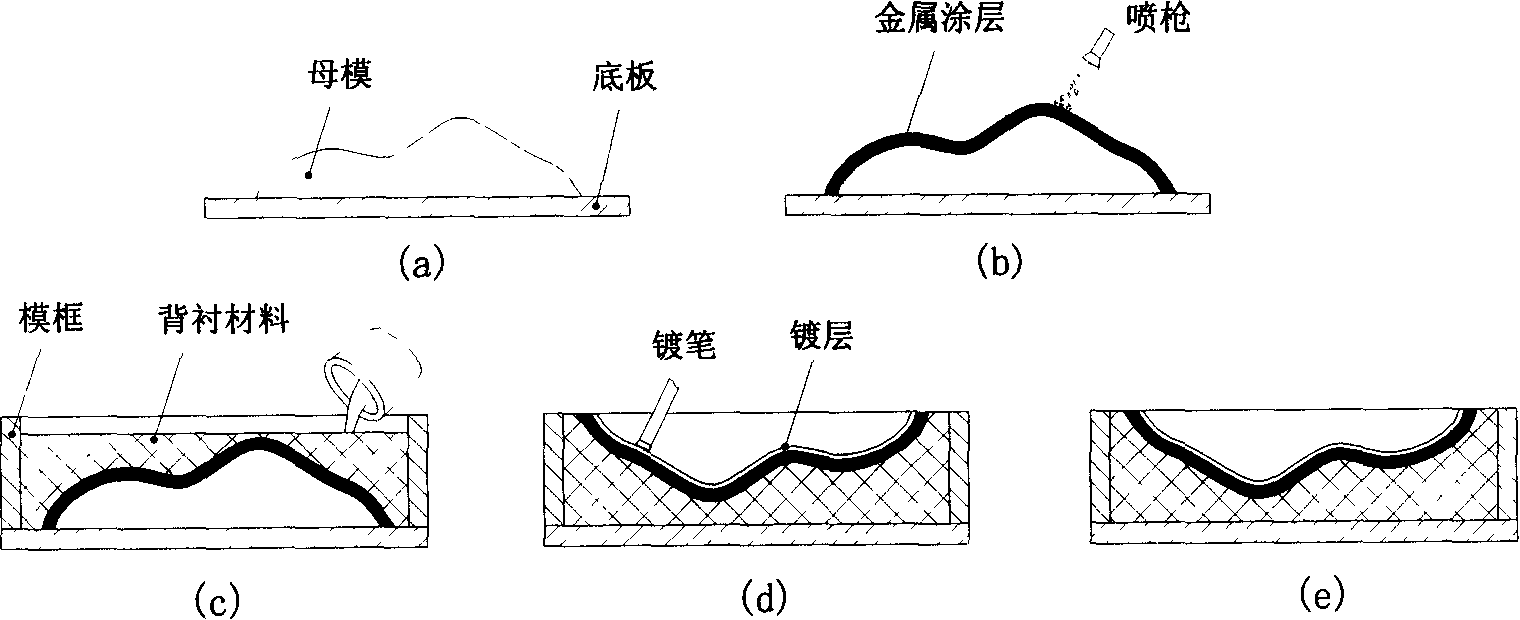

[0027] figure 1 and figure 2 The technical approach and process route for the rapid manufacture of metal spraying molds using this equipment are given.

[0028] Among them, (a) surface polishing of the master mold: first apply a layer of release agent, then evenly apply a layer of release agent, and let it stand for about 30 minutes. (b) Spray the molding metal with an arc spray gun to form a thin metal shell with a certain thickness. During the working process, the axis of the spray gun is always perpendicular to the curved surface where the working point is located. Cut off unnecessary parts afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com