Coating machine for wall coatings

A technology of spraying machine and paint, which is applied in the direction of coating, spraying device, and device for coating liquid on the surface, etc. It can solve the problems of slow straight brushing speed, paint consumption, and labor-consuming, etc., and achieves fast spraying speed, simple structure, Portable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

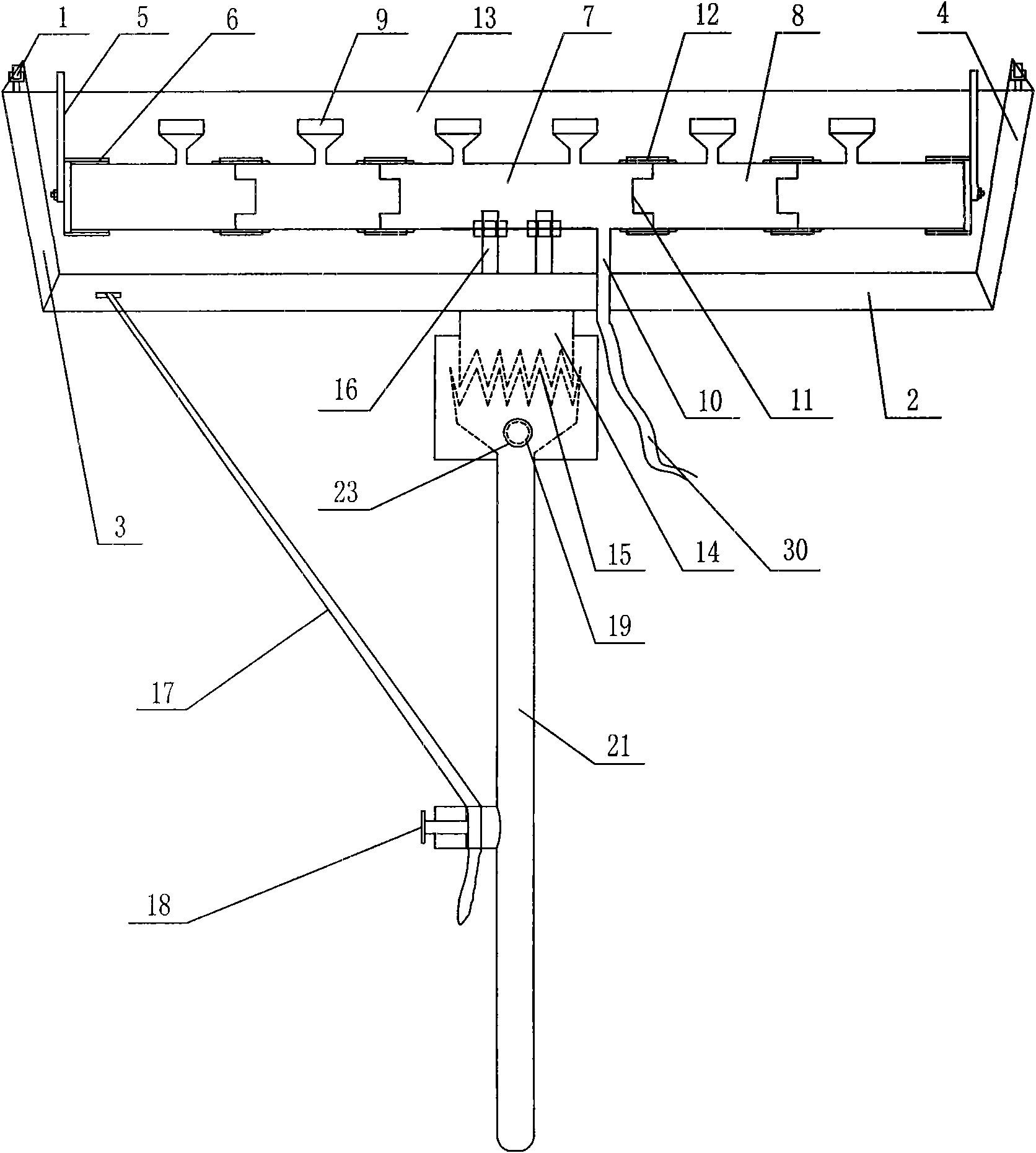

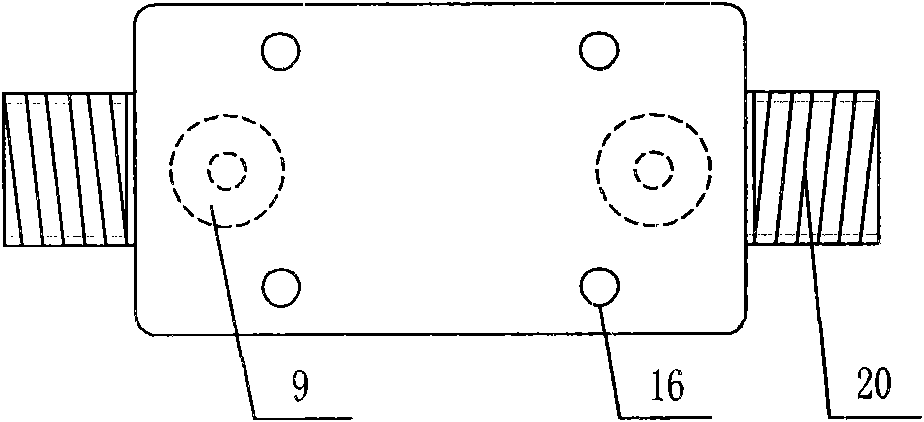

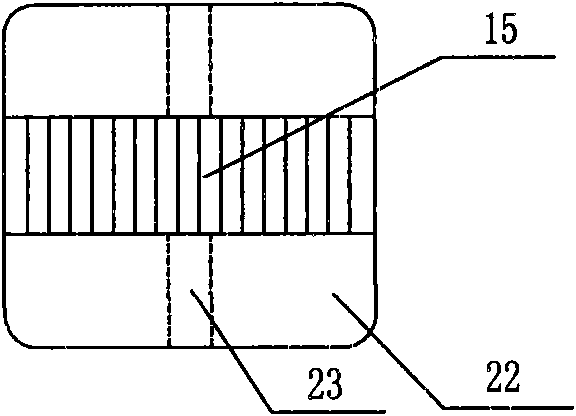

[0018] The present invention is a kind of wall paint spraying machine, as figure 1 , figure 2 As shown, including the main board 2, the inner surface of the main board 2 is fixedly provided with a tubular main nozzle part 7 with a bolt connector 16, the front of the main nozzle part 7 is provided with a nozzle 9, and the rear of the main nozzle part 7 is provided with a The feed pipe 10 and the two ends of the main nozzle part 7 are closed with the end cap 6, and the liquid baffle 5 is arranged on the outer end surface of the end cap 6, and the liquid baffle 5 is fixed with bolts, and the opening and closing angle of the liquid baffle 5 can be adjusted by the bolts.

[0019] Both ends of the main spray head part 7 are concave tenon-tenon joints 11, one end of the additional spray head part 8 is concave-shaped tenon joints 11, and the other end is convex-shaped tenon tenon joints 11. The two ends of the main nozzle part 7 are connected by mortise and tenon 11 to add an additi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com