Hub spraying equipment

A technology of spraying equipment and wheel hubs, applied in the direction of coating, spray booth, spraying device, etc., can solve the problems that raw materials cannot be dried quickly, affect processing efficiency, uneven spraying, etc., achieve fast spraying speed, reduce working time, and reduce gas. Scattered effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

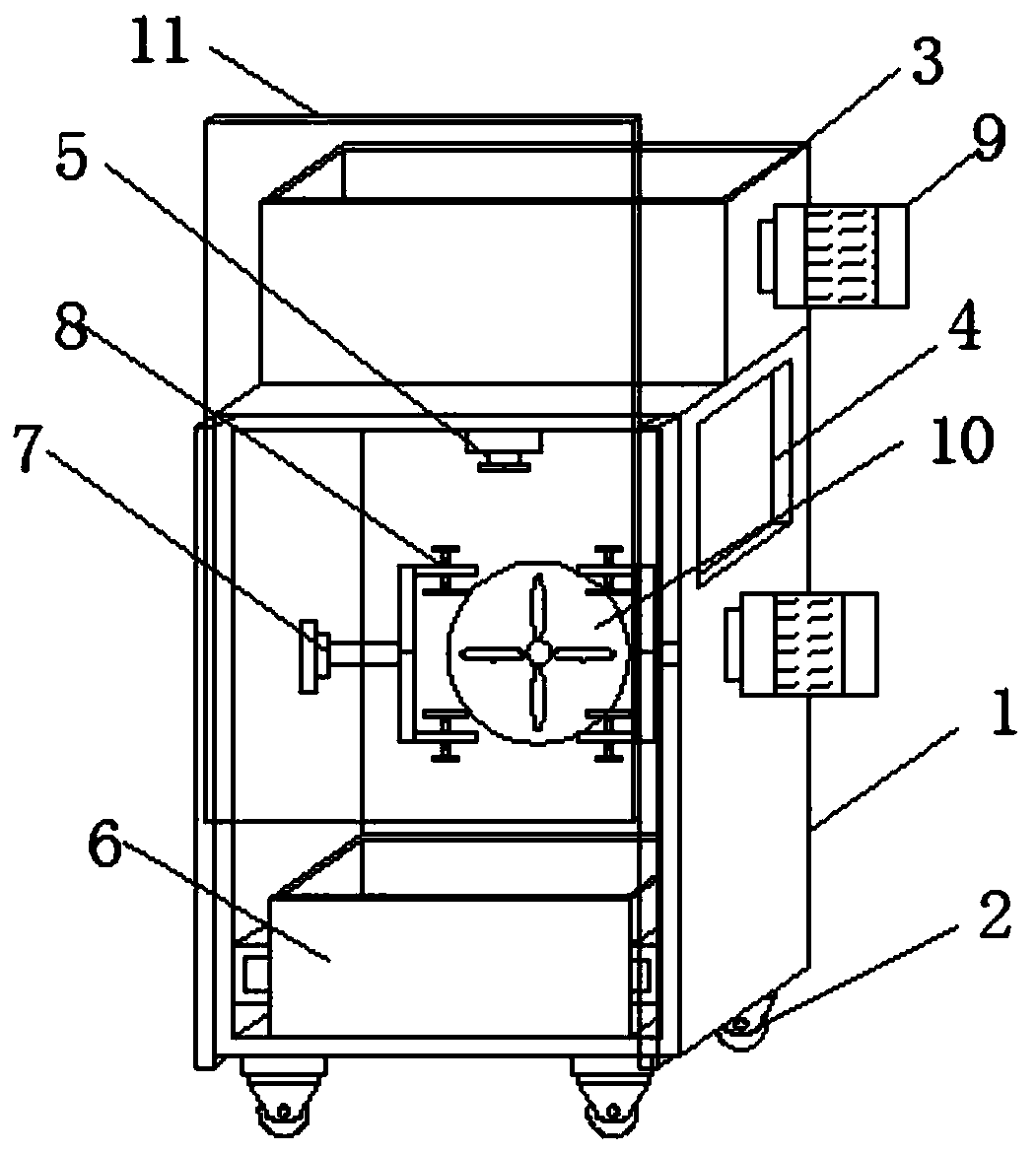

[0038] Embodiment 1: as figure 1 — Image 6 , a wheel hub spraying equipment, comprising: a box body 1, a universal wheel 2 is fixed on the top of the box body 1, and a material storage tank 3 is fixed on the top of the box body 1, and a vent 4 is opened on one side of the box body 1, The inside of the box body 1 is fixed with a shower head 5, and the shower head 5 passes through the top of the box body 1 and is fixedly connected with the storage tank 3, and the air vent 4 can discharge the gas in the box body;

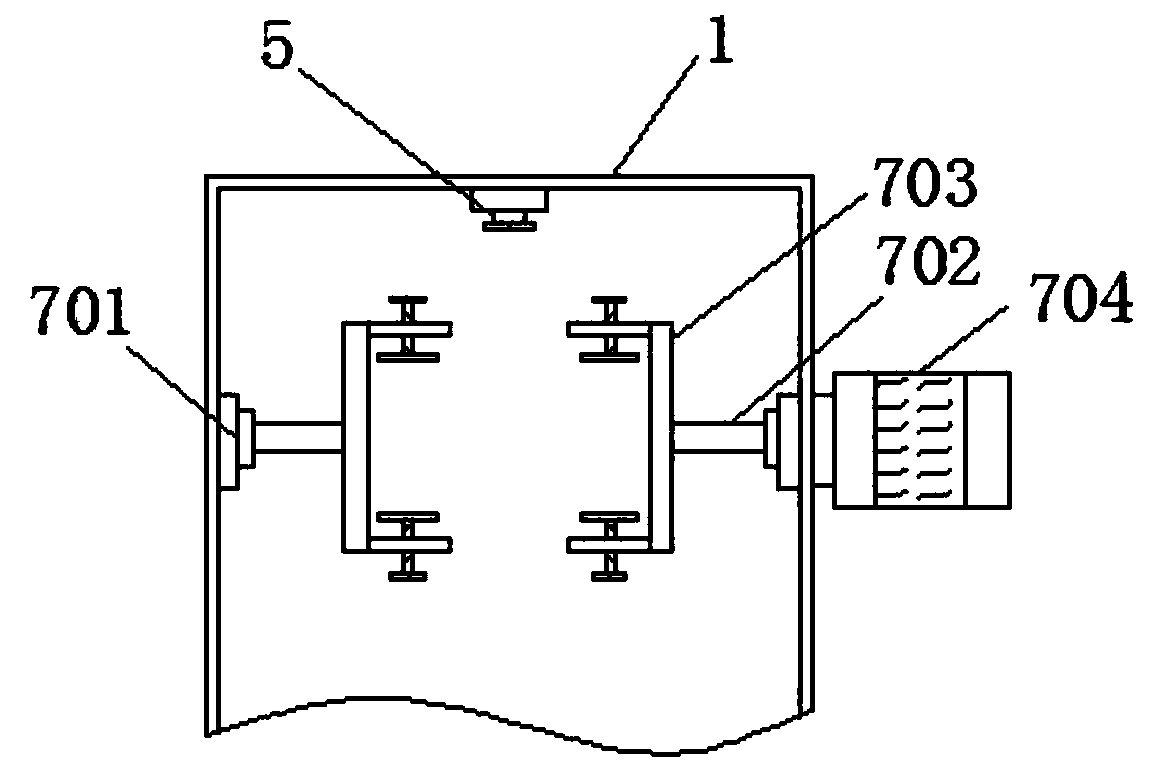

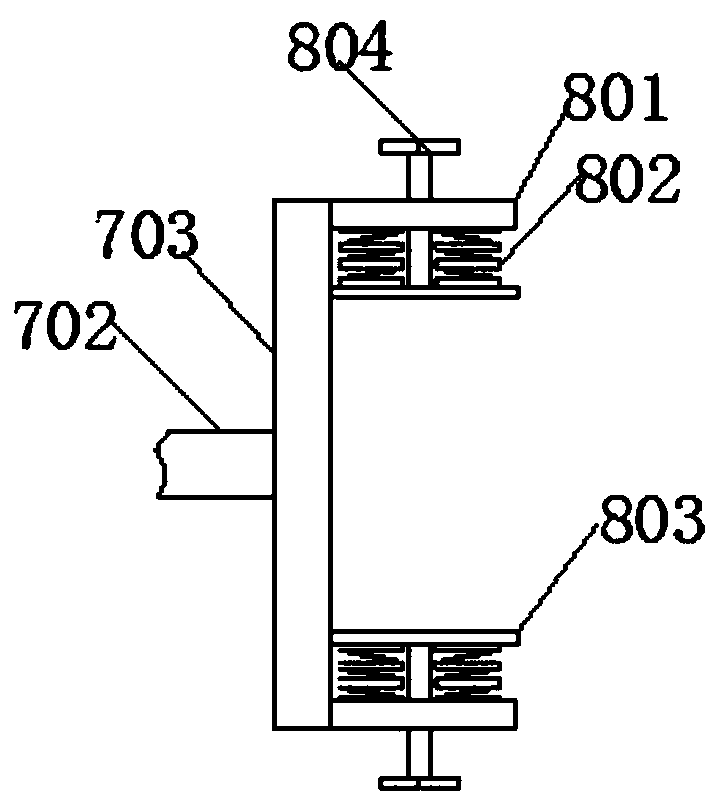

[0039] The bottom end of the casing 1 is equipped with a collection box 6, and the inside of the casing 1 is equipped with a clamping mechanism 7, and the inside of the clamping mechanism 7 includes a first rotating shaft 701, and the connection between the first rotating shaft 701 and the casing 1 The connection between them is fixed, and the side of the first rotating shaft 701 close to the center line of the box body 1 is fixedly connected with a connecting rod 70...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com