Box body coating machine

A spraying machine and box body technology, applied in the field of box body spraying machine, can solve the problems of poor spraying quality, low efficiency, time-consuming and laborious, etc., and achieve the effect of easy operation, fast spraying speed and uniform spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

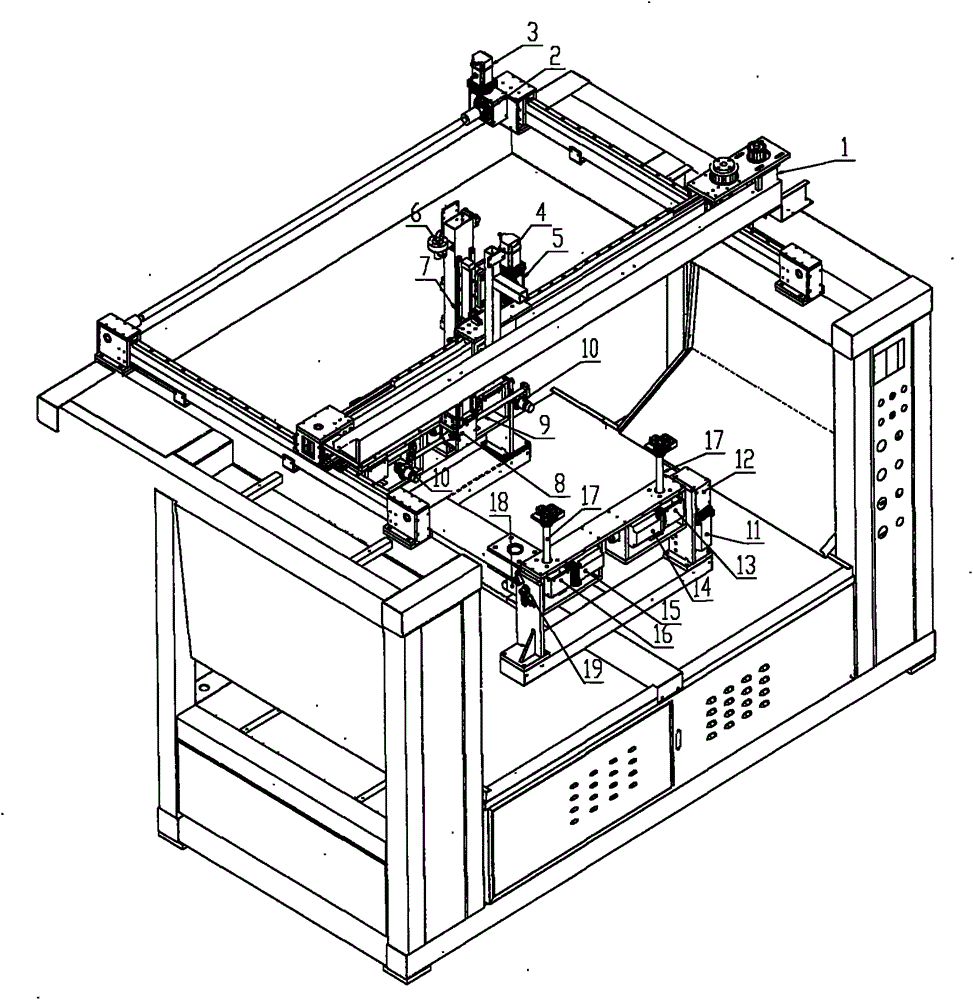

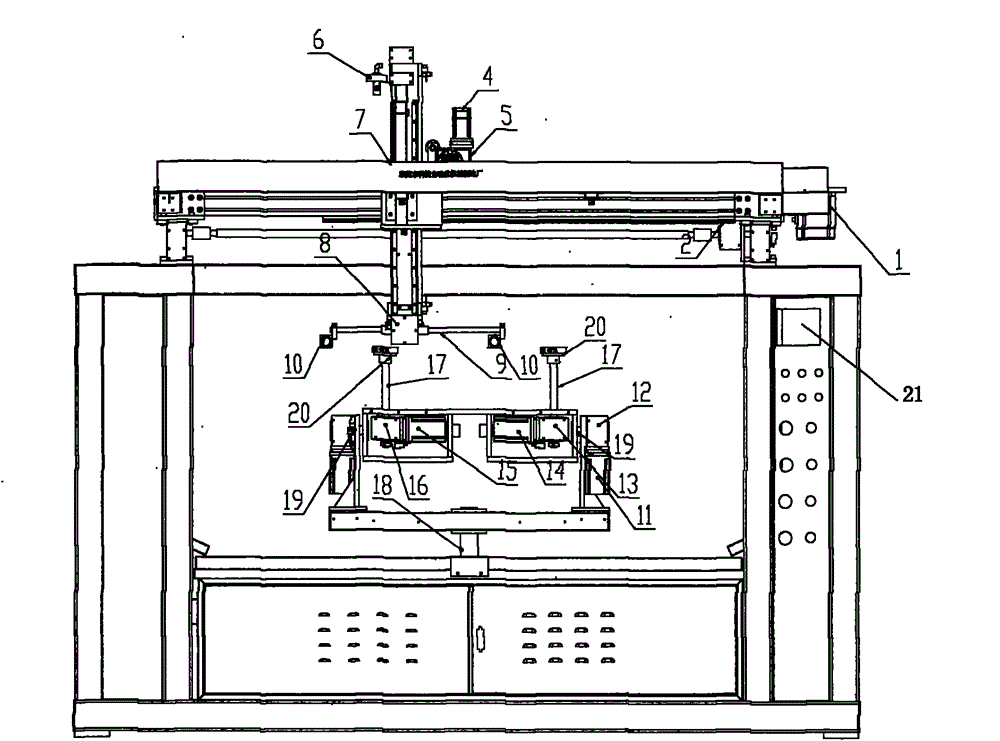

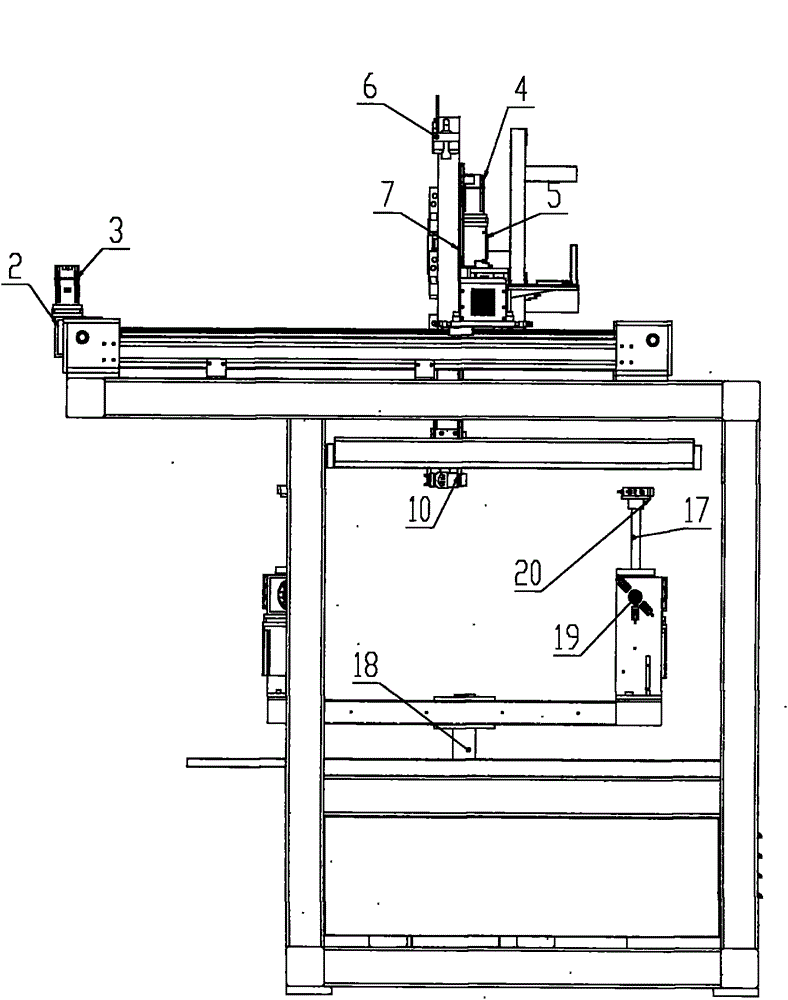

[0018] refer to figure 1 --- Figure 4 As shown, design a kind of box body spraying machine, comprise machine base, be arranged on the frame on the machine base, be provided with working platform and workpiece fixing fixture 20 on described machine base, be provided with for The first motor 14 that rotates the workpiece by 90 degrees and the matching reducer 13, the second motor 15 that rotates the workpiece by another 90 degrees and the second reducer 16 that matches it, and the workpiece rotation axis that rotates the workpiece 17, the workpiece refueling shaft 18 that is used to change the workpiece to the spraying area, the vertical shaft 19 and the drive motor 11 that are used to control the conversion of the fixed fixture 20 between the horizontal plane and the vertical plane; On the frame, the X-axis that makes the spray gun move left and right and the X-axis motor 1 and reducer used in conjunction with it, the Y-axis that makes the spray gun move back and forth and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com