A double-sided maintenance device and method for high-speed rail prefabricated bridges

A bridge and bottom surface technology, applied in the field of maintenance systems, can solve the problems of inability to meet long-distance multi-section bridge maintenance, inability to humidify and cool the bridge maintenance, low intelligence, etc., to prevent waste of water resources, good maintenance effect, and spray efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

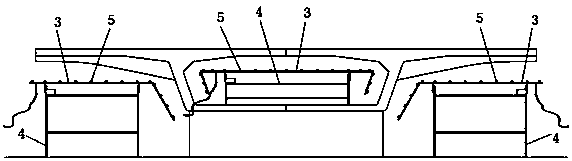

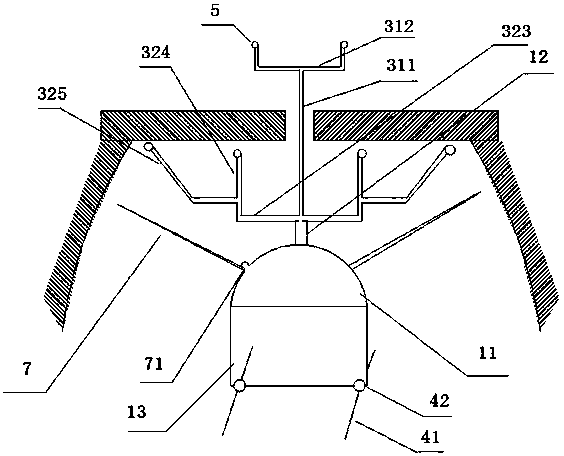

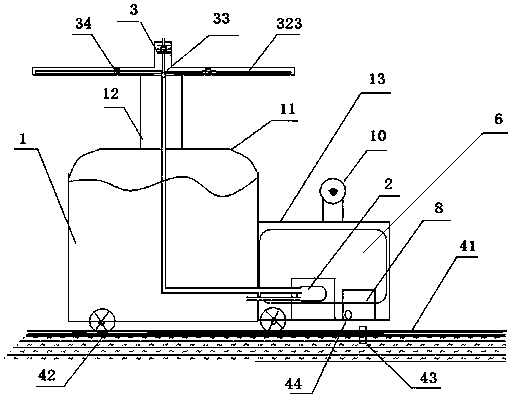

[0037] Such as figure 1 As shown, a double-sided maintenance device for a high-speed rail prefabricated bridge of the present invention includes a water tank 1, a water pump 2, a spray pipe 3 and a running mechanism 4, the water pump 2 is connected to the water tank 1 and the spray pipe 3, and the spray pipe 3 includes a top surface The spray group 31 and the bottom surface spray group 32, 31 top surface spray group are T-shaped, the T-shaped vertical pipe 311 passes through the gap between the two adjacent beam flanks, and the T-shaped horizontal straight pipe 312 is provided with nozzles 5, The top surface spraying group 31 is used for humidifying and cooling the top surface of the prefabricated bridge; the bottom surface spraying group 32 is used for humidifying and cooling the bottom surface of the prefabricated bridge. The movement of the traveling mechanism 4 drives the movement of the nozzle 5 relative to the position of the bridge. 2. It is connected with the power dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com