Re-griding-cutting cube boron-nitride grinding-block device, its base and grinding-block preparing method

A cubic boron nitride and grinding block technology, applied in the field of machinery, can solve problems such as reducing the time for clamping and tool setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

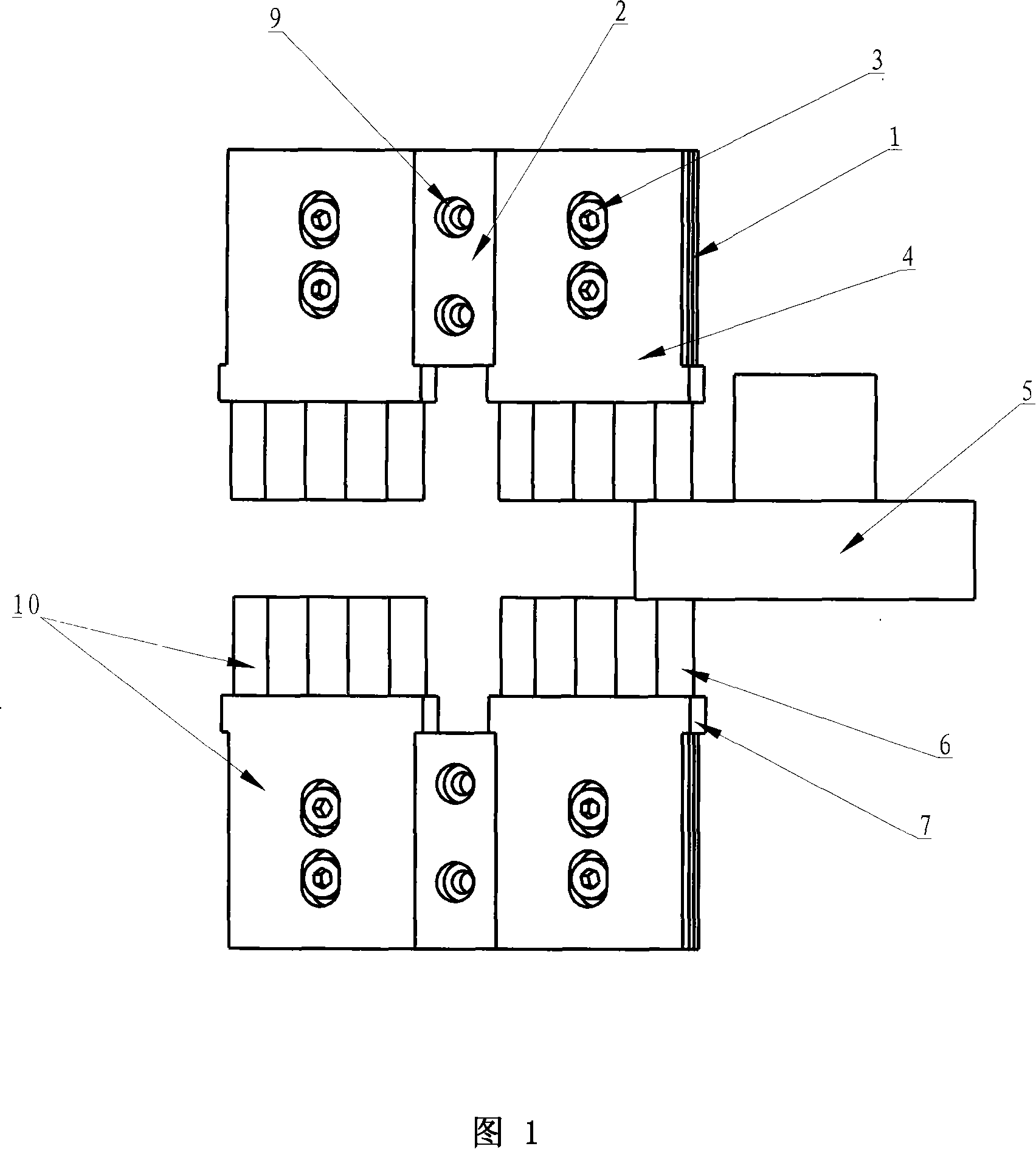

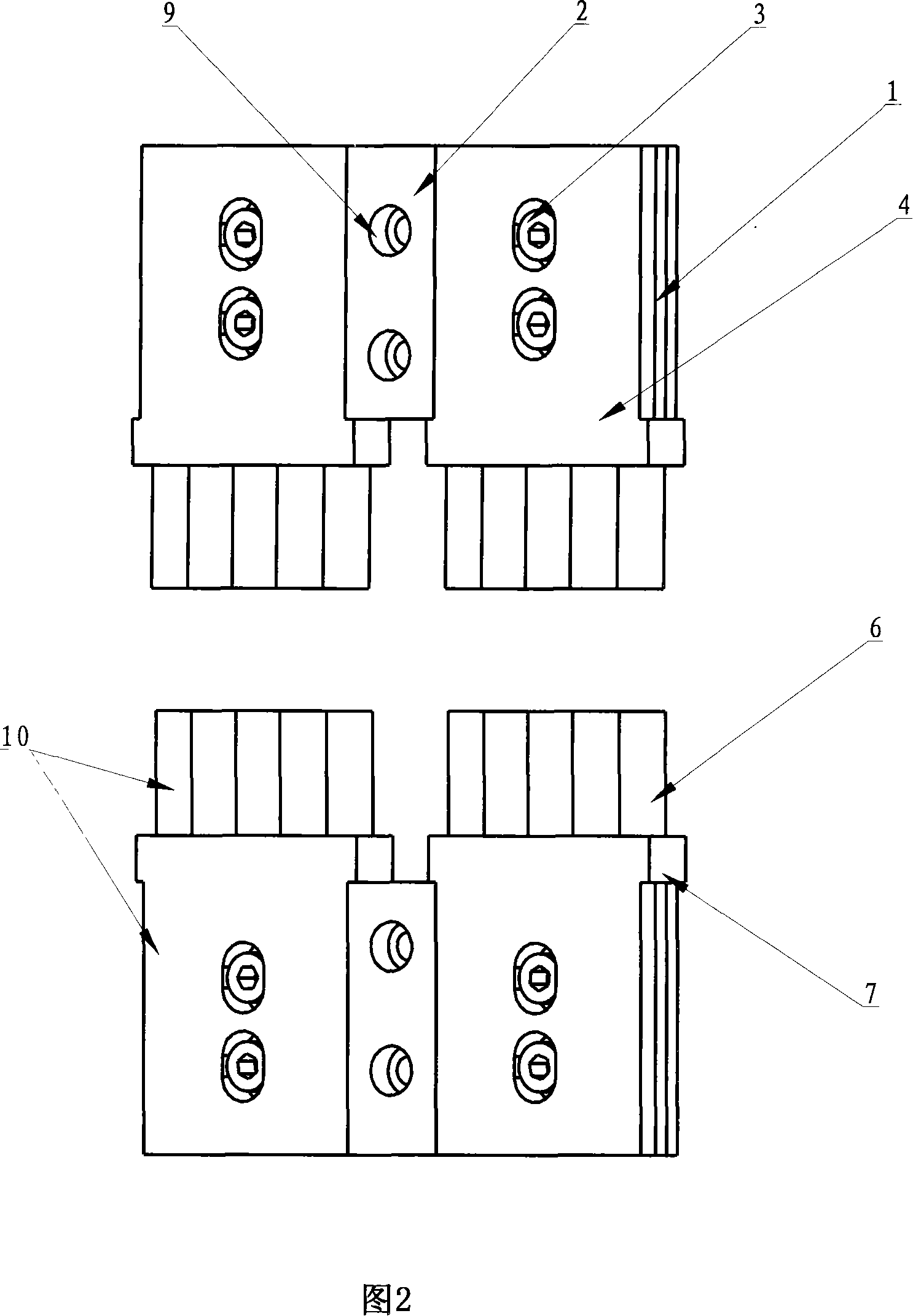

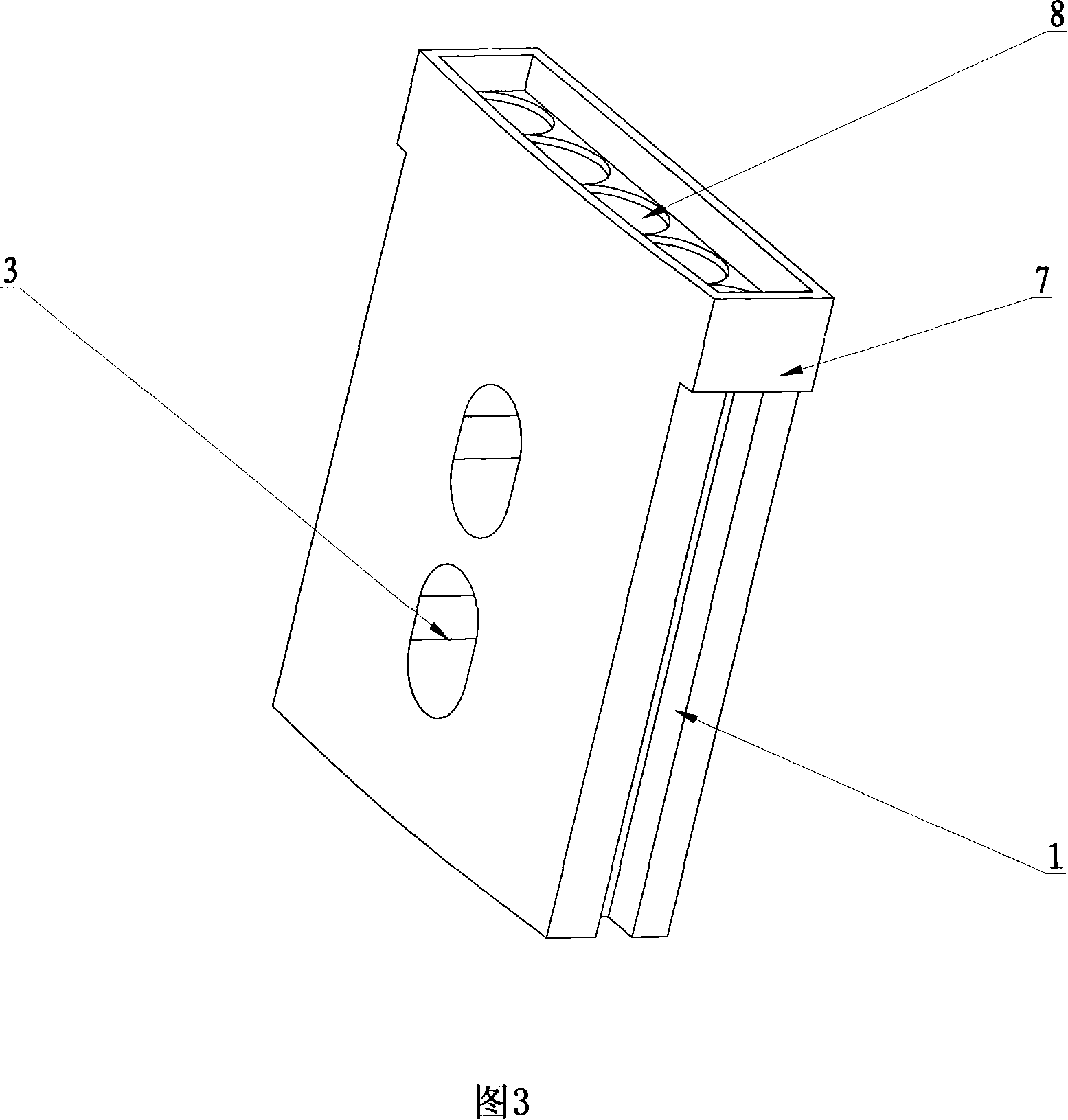

[0112] Please refer to accompanying drawings 1,2,3 shown, the present invention is made up of parts such as base, grinder equipment, grinding tool, square grinding block and each tooling parts, and this device is inlaid on the aluminum alloy base 4 of precise processing five A cylindrical cubic boron nitride CBN grinding body is combined into an integral cubic boron nitride CBN grinding block 10, wherein:

[0113] In one end of the aluminum alloy base 4, 5 pieces of cubic boron nitride grinding blocks 6 are respectively bonded and embedded in the inlaid position hole 8, and the size of each hole 8 of the inlaid position hole 8 is respectively the same as that of the 5 6 diameters of the cubic boron nitride grinding block. matched in size;

[0114]In the middle of the aluminum alloy base 4, there are two upper and lower clamping bolts 3, and the clamping bolts 3 are connected and fixed with the grinding machine equipment;

[0115] On both sides of the aluminum alloy base 4, re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com