Packaging bag with steam releasing function and packaging body using the packaging bag

A packaging bag and steam technology, which is applied in the field of packaging bags, can solve the problem of microwave ovens that are difficult to contain, and achieve the effect of high degree of freedom.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

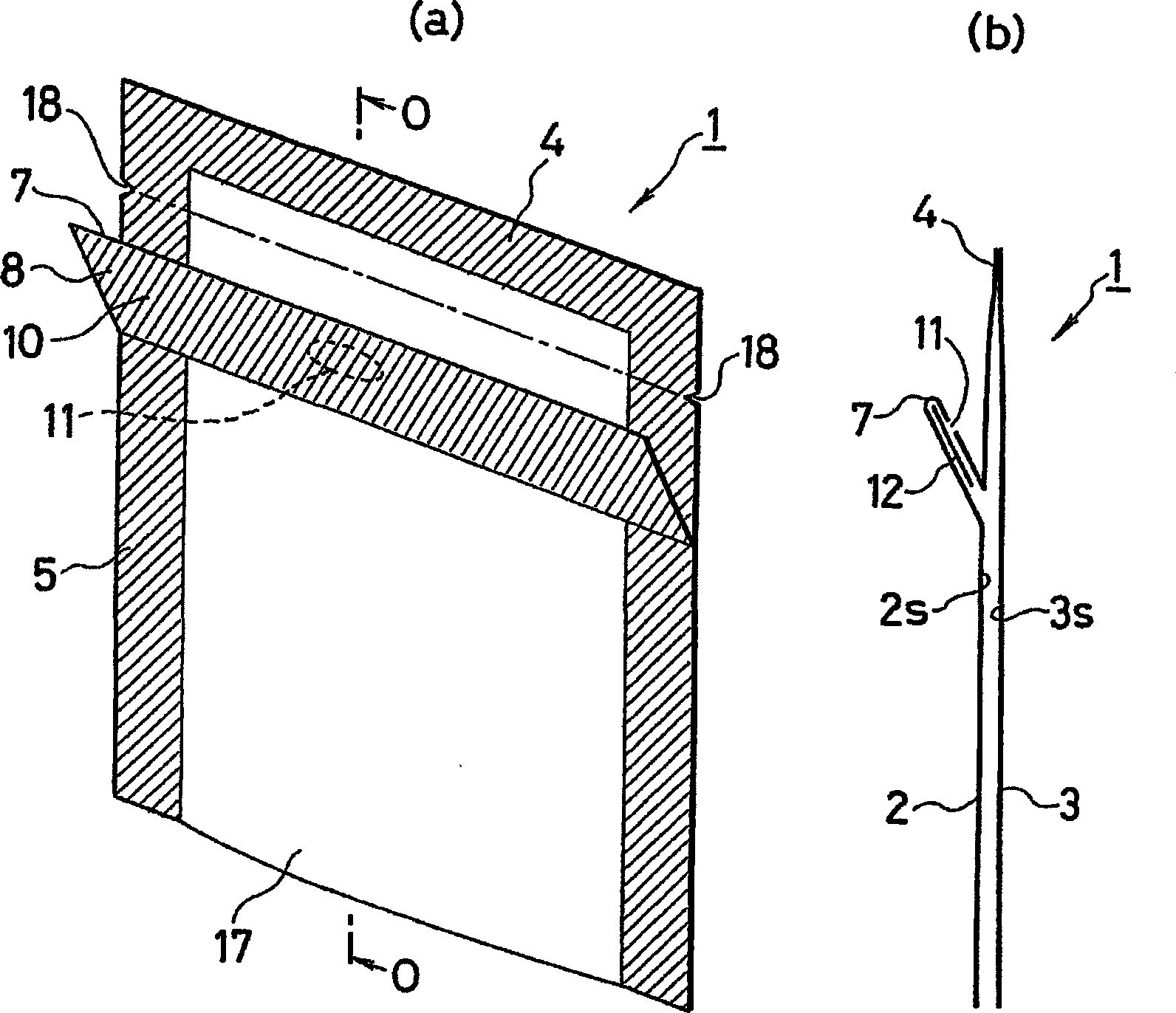

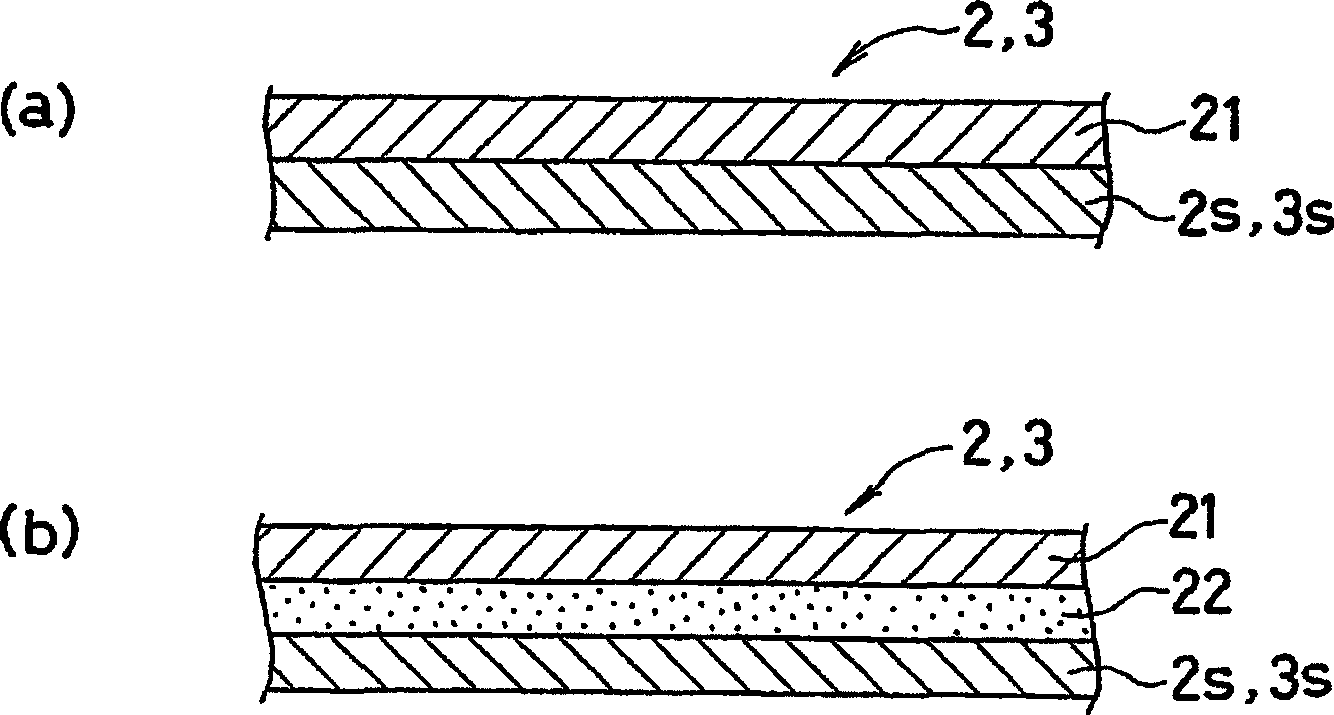

[0067] As the packaging bag 1 according to the first embodiment of the present invention, the main film 2 on the outside and the main film 3 on the back side are laminated respectively as laminated films. figure 1 As shown in (b), the heat-adhesive sealant layers 2 s and 3 s formed by laminating on the laminated surface thereof heat-weld the periphery of the end portion by heat sealing to form the bottom seal portion 4 and the side seal portions 5 on both sides. , 5, so that it can accommodate the contents A such as solid.

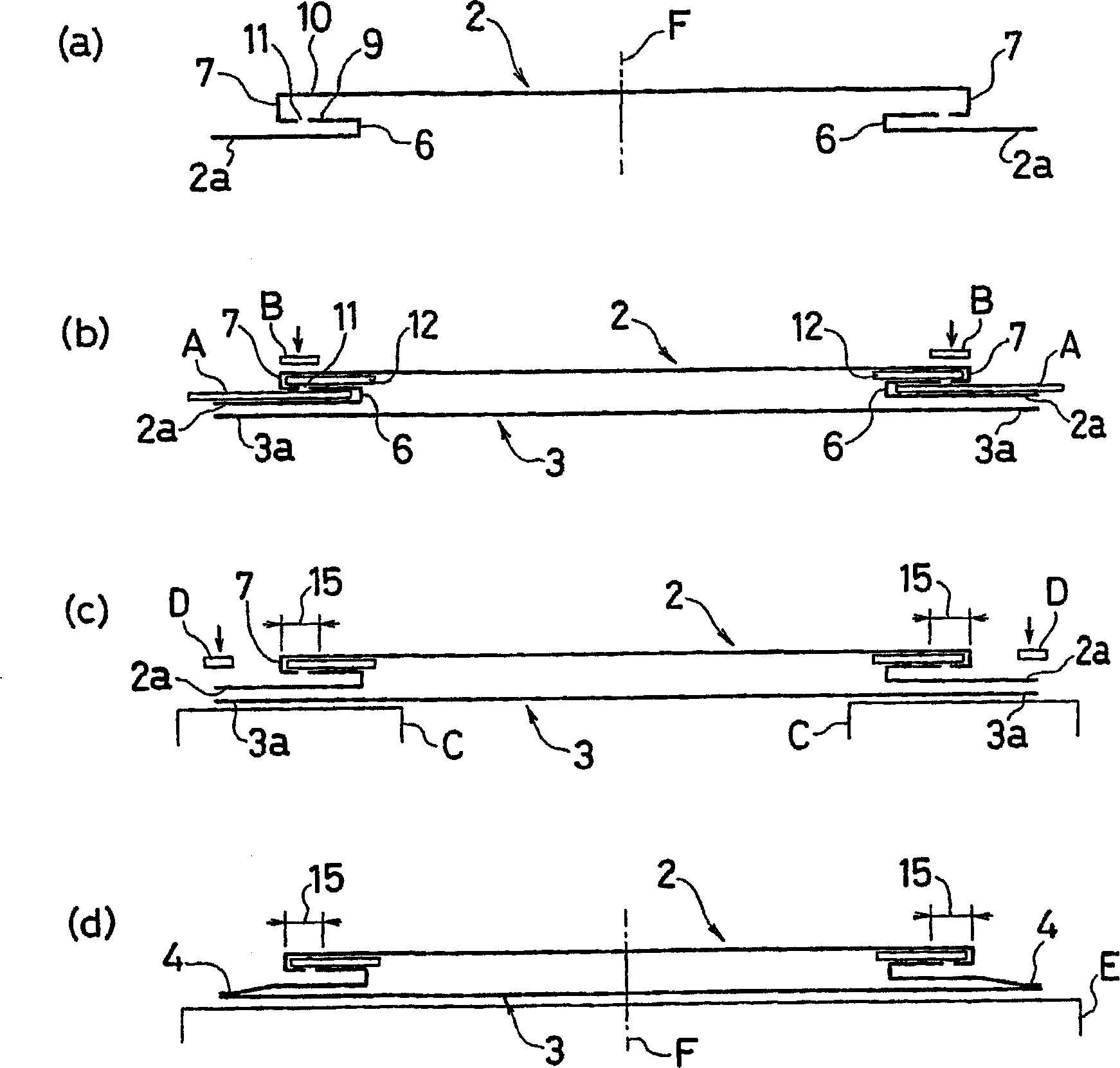

[0068] On the above-mentioned outer main body film 2, the main body film 2 on the outer side is first folded back toward the bottom sealing part 4 side on the bottom sealing part 4 side and parallel to the bottom sealing part 4 throughout the entire transverse width of the bag, and then the folded The main body film 2 folded from the groove end (valley fold り end) 6 to the bottom seal portion 4 side is bent parallel to the bottom seal portion 4 from the p...

no. 2 approach

[0103] Figure 6 ~ Figure 9 The second embodiment of the present invention is shown.

[0104] In this example, the upper edge portion of the folded top end 7 along the folded-in portion 8 is heat-sealed over the width direction of the bag to form the airtight closure portion 15 . And, in the above-mentioned sealed closing part 15, there are three non-sealed parts 23 composed of an non-sealed area connected to the folded top end 7 on one side and surrounded by the sealed area on three sides, and the above-mentioned steam removal port 11 is located on the non-sealed part 23 . The steam removal port 11 is formed by integrally cutting the inner panel surface 9 , the easy-peeling tape 12 , and the outer panel surface 10 of the non-sealed portion 23 .

[0105] The above-mentioned sealing area is a part of the sealing and closing part 15 where the easy-peeling tape 12 is located between the inner panel surface 9 and the outer panel surface 10 as described above and is integrally he...

no. 3 approach

[0129] Figure 10 shows the third embodiment. In this embodiment, at the center of the tuck-in portion 8 , a seal closing portion 15 is formed in connection with the tuck-in tip 7 , and is not connected to the side seal portions 5 on both sides of the tuck-in portion 8 via an unsealed portion 27 . In addition, the above-mentioned sealed closing portion 15 has a non-sealed portion 23 connected to the folded tip 7, and the non-sealed portion 23 is formed with a notched steam removal port 11. Furthermore, on the lower side of the airtight closing part 15, the lower side is made into the inclined lower side 28 left and right.

[0130]Furthermore, as shown in the figure, an extended seal portion 29 extending toward the center of the bag is provided on the side seal portion 5 opposite to the bottom seal portion 4 at a position close to the folded portion 8 . Since the extended sealing portion 29 is provided in this way, when the package obtained from the packaging bag 1 is heated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com