Online adjustable fixture for polishing machine tool

An adjustable and fixture technology, applied in the field of fixtures, can solve problems such as uneven distribution of work load, influence on polishing effect, and poor safety, so as to avoid uneven distribution of work load, improve polishing effect, and improve safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

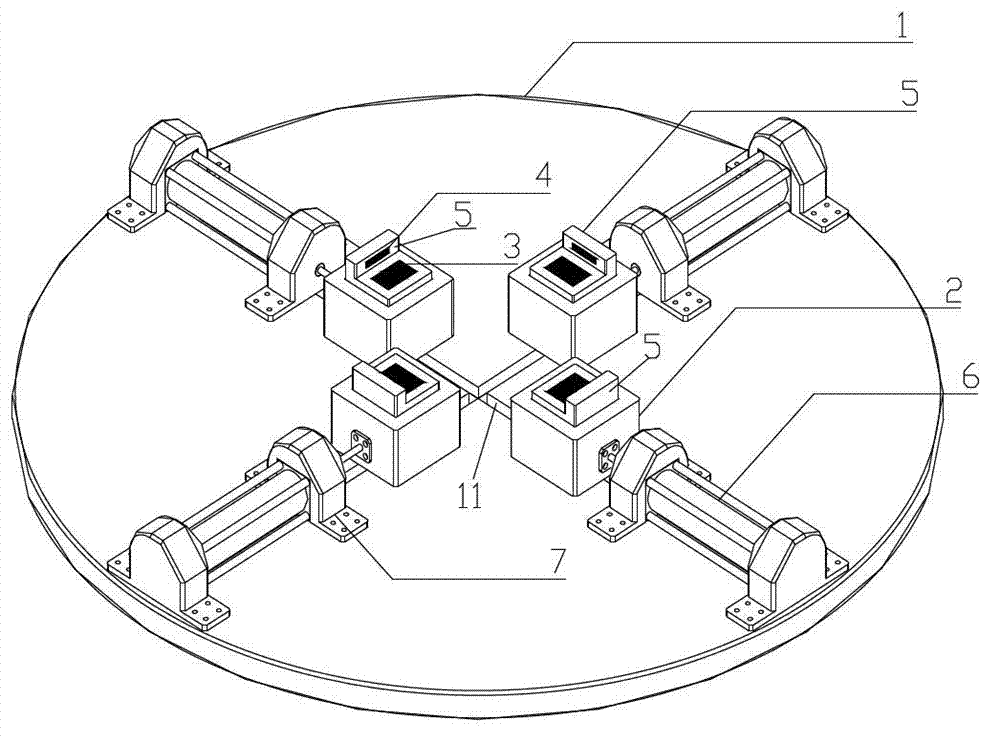

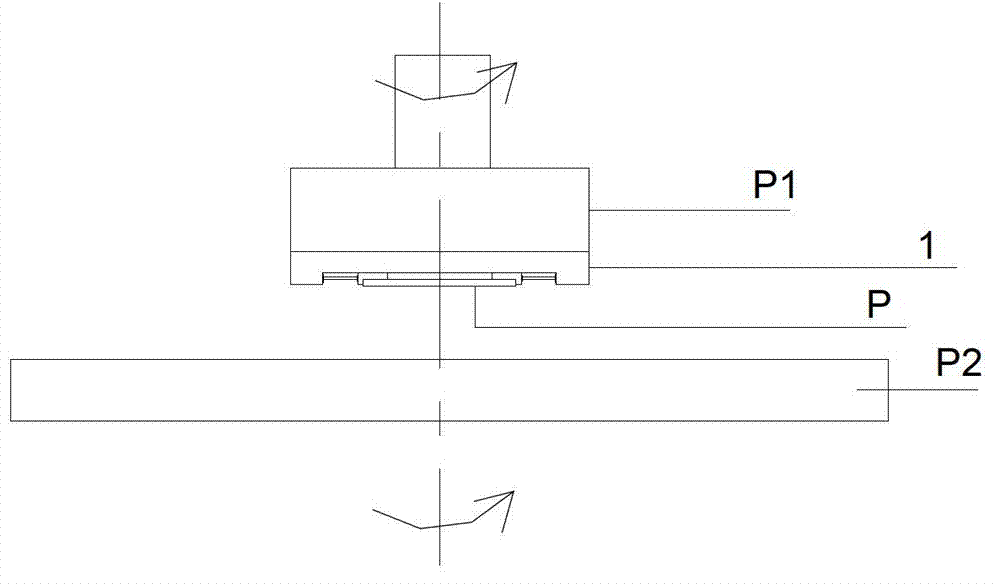

[0014] see Figure 1~3 , the embodiment of the present invention is provided with a chassis 1 (circular) and 4 sets of clamping adjustment mechanisms with the same structure; 4 sets of clamping adjustment mechanisms are installed on the surface of the chassis 1 in a centripetal manner based on the central axis of the chassis 1 .

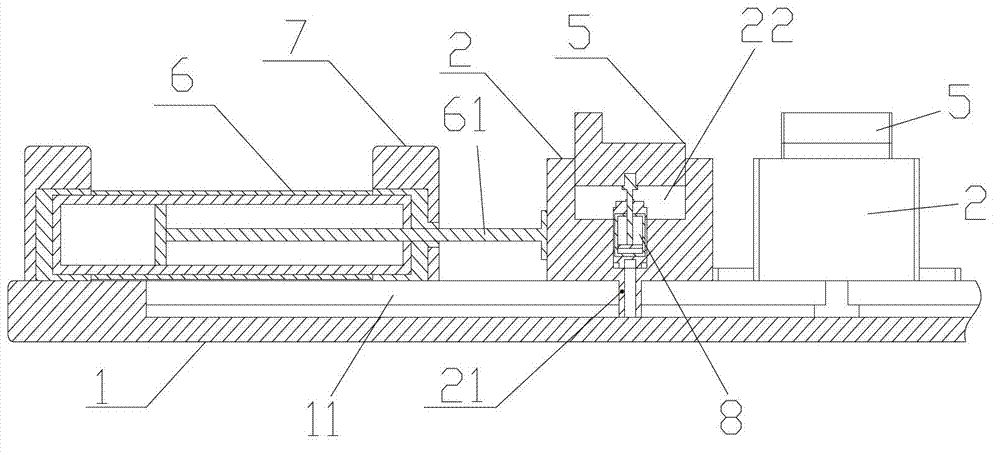

[0015] The clamping adjustment mechanism is provided with a horizontal slider 2, a horizontal cylinder 6, a vertical slider 5, a vertical cylinder 8, a vertical pressure sensor 3 and a horizontal pressure sensor 4 with adjustable response speed. The chassis 1 is provided with four identical horizontal guide grooves 11 in the shape of a cross, and the horizontal guide grooves 11 are in corresponding sliding fit with the protrusions 21 provided at the bottom of the horizontal slider 2 . The piston rod 61 of the horizontal cylinder 6 is connected with the horizontal slider 2 . Each horizontal cylinder 6 is fixed on the surface of the chassis 1 by a fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com