Downhole confining pressure abrasive material jet flow simulation experimental device and method

A simulated experimental device and abrasive jet technology, applied in the field of water jet, can solve the problems of unclear observation of the experimental process, small pressure, troublesome operation, etc., and achieve the effects of saving experimental funds, simplicity and efficiency, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

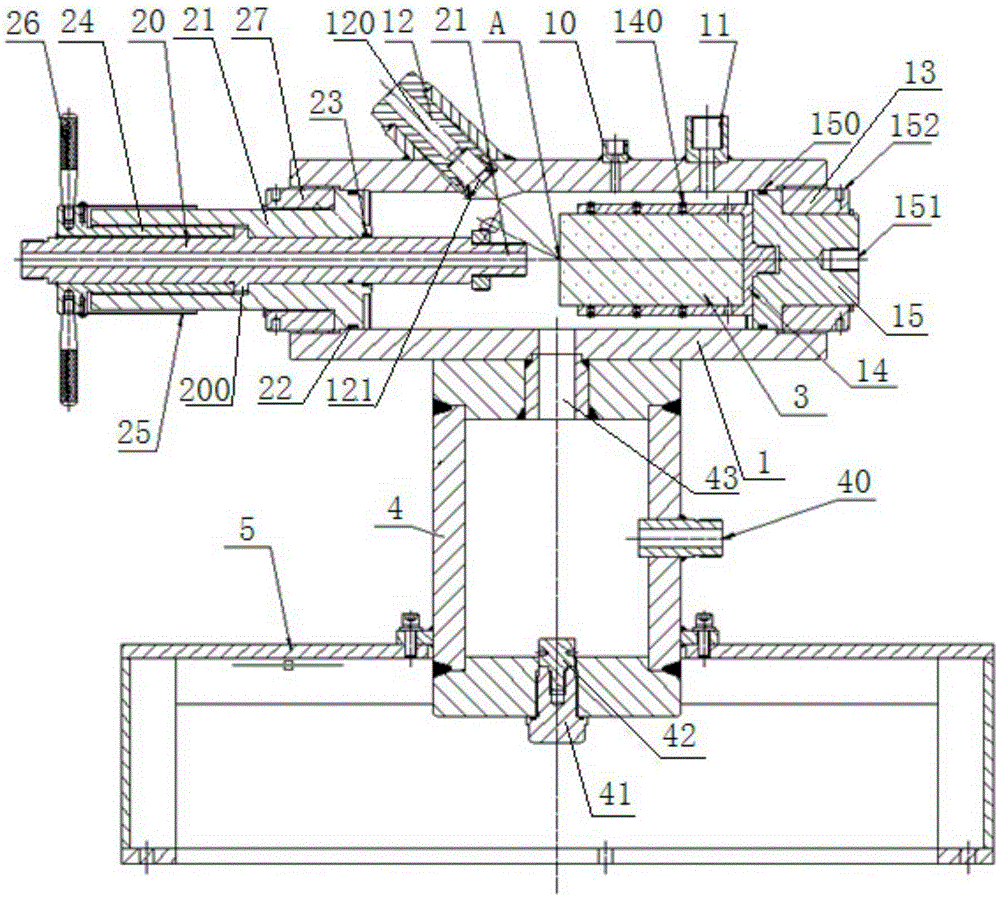

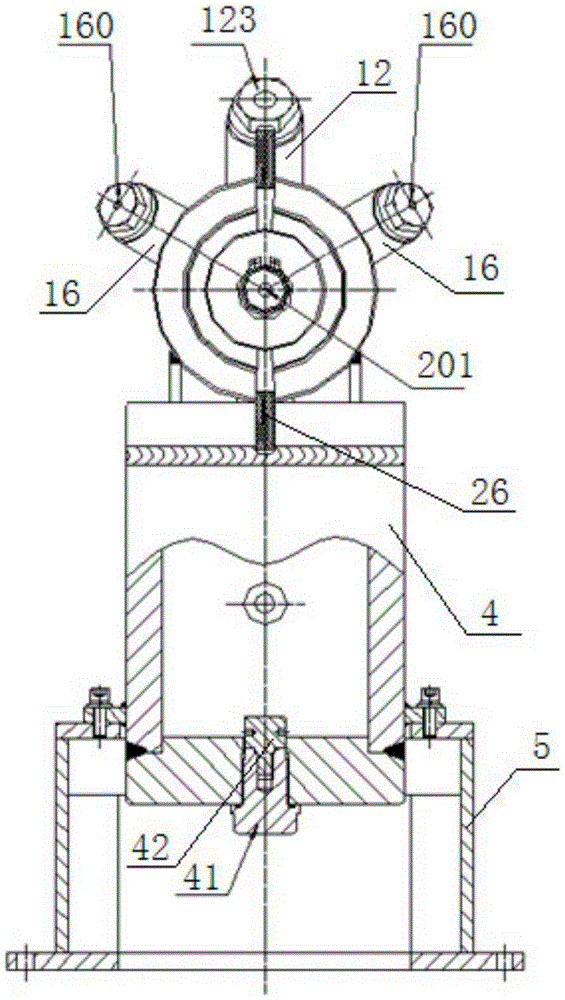

[0031] See Figure 1~2 A downhole confining pressure abrasive jet simulation experiment device is shown, the confining pressure cylinder 1 is the experimental chamber of the abrasive jet experiment, which is used to simulate the environment required for the experiment; the specimen clamping assembly is used to hold the specimen 3 in the experimental Positioning in the cabin; the nozzle installation adjustment component is used to introduce the abrasive jet, so that the abrasive jet can erode the test piece 3; it uses a sapphire high-pressure lens 121 and a high-speed camera for image recording of the abrasive jet’s erosion process on the test piece 3 ; Its fiber optic light source is used for illumination to improve the quality of image recording. In addition, the simulated experimental device of this scheme is also equipped with a storage tank 4 to co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com