Zero arc extinguishing device

An arc extinguishing device and arc flashover technology, applied in circuit breaker parts, electrical components, electrical switches, etc., can solve the problems of difficult to achieve small volume, high breaking and zero arc flashover, and large volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the accompanying drawings and examples.

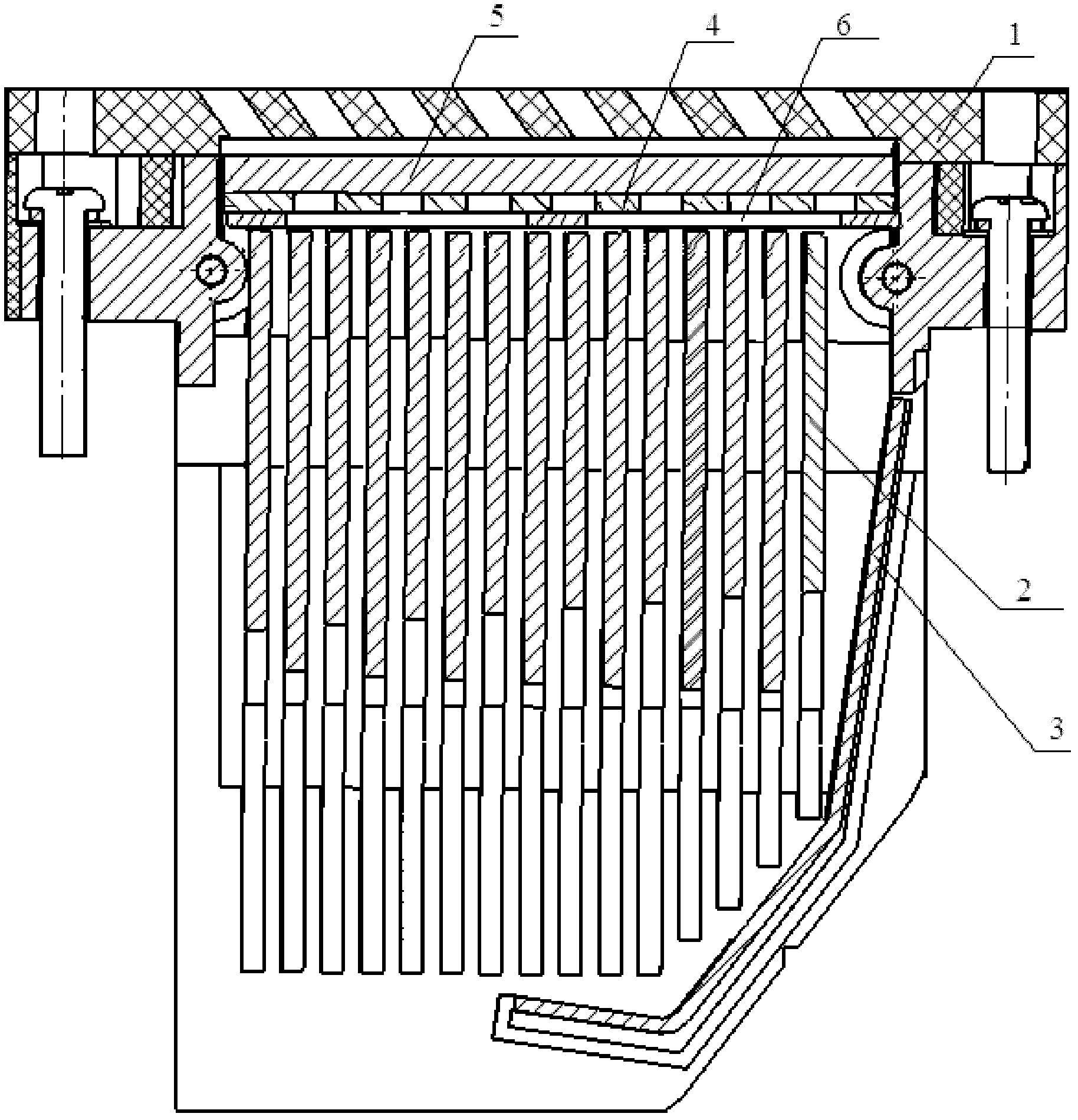

[0021] The invention provides a zero flashover arc extinguishing device, such as figure 1 shown. The arc extinguishing device includes an arc shield 1 , an arc striker 3 , two arc shields, a grid 2 , an insulating frame 6 , an arc extinguisher 4 and a deionizing net 5 .

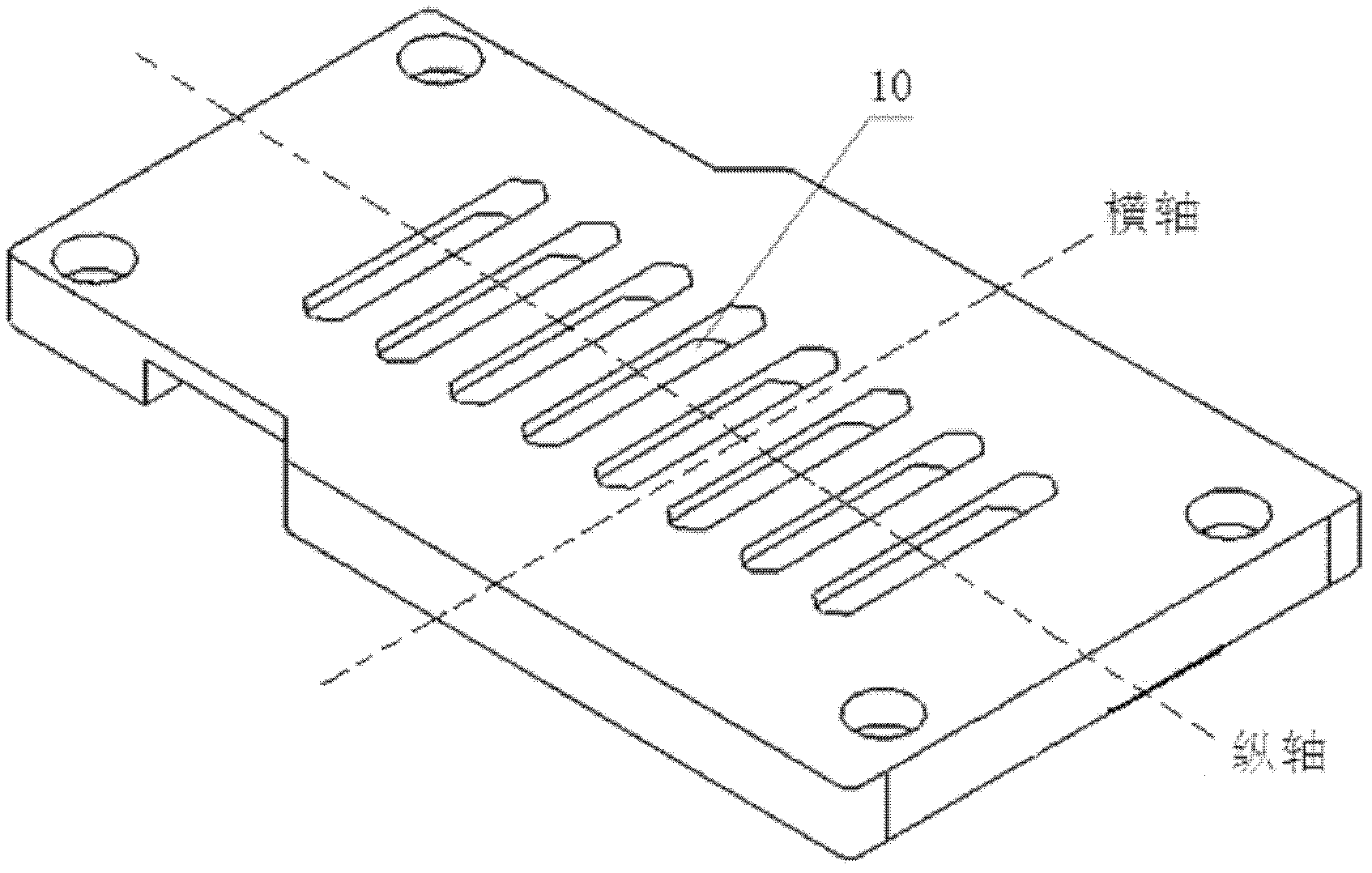

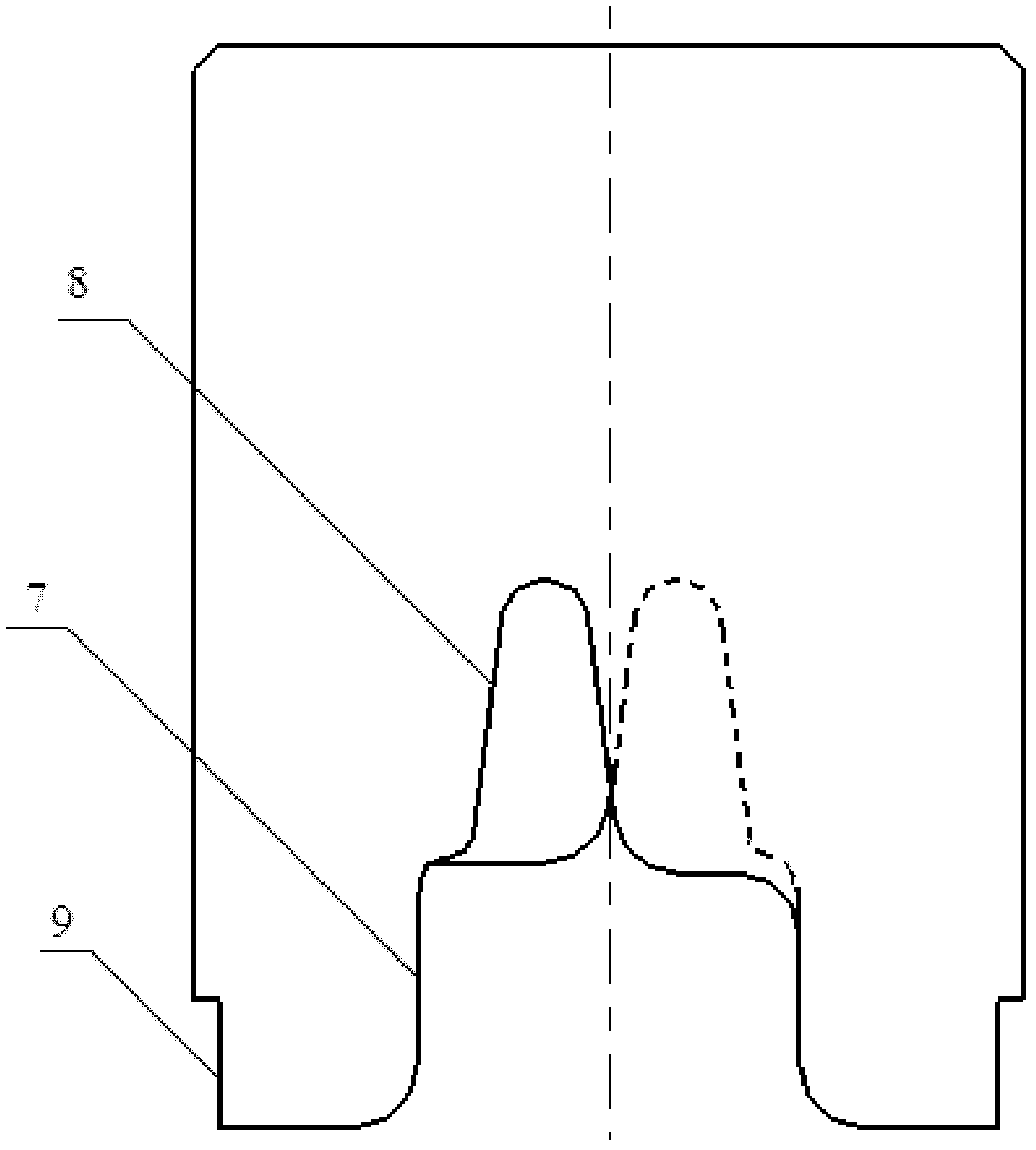

[0022] The connection relationship is: the protrusions on the top of the two arc-proof walls match the grooves on the bottom of the arc-proof cover 1 to realize the positioning of the arc-break cover 1, and the two arc-break walls are fixed to the arc-break cover 1 by screws . Sixteen pairs of longitudinal slots are processed on the inner walls of the two arc partitions. Fifteen grid pieces 2 are inserted into the slots one by one and the other is reversed. The arc starting piece 3 is a bent sheet structure, and one side is vertical , the other side is inclined to the lower left, and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com