Spark plug

A spark plug and insulator technology, applied in the field of spark plugs, can solve problems such as hindering the reduction of the diameter of spark plugs, unable to meet the reduction of the diameter of engine spark plugs, etc., and achieves the effects of improving reliability, improving vibration resistance, and increasing vibration frequency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

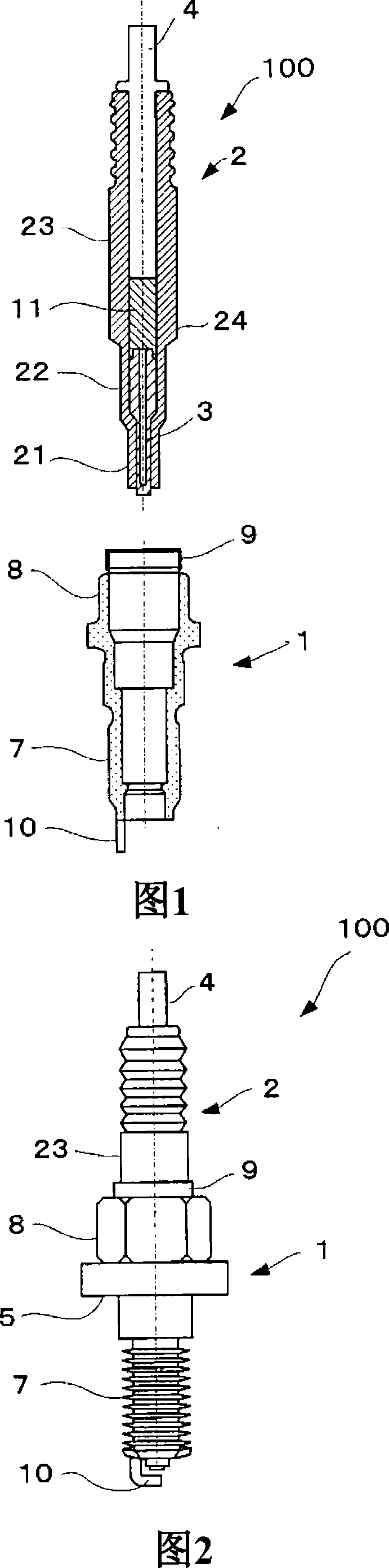

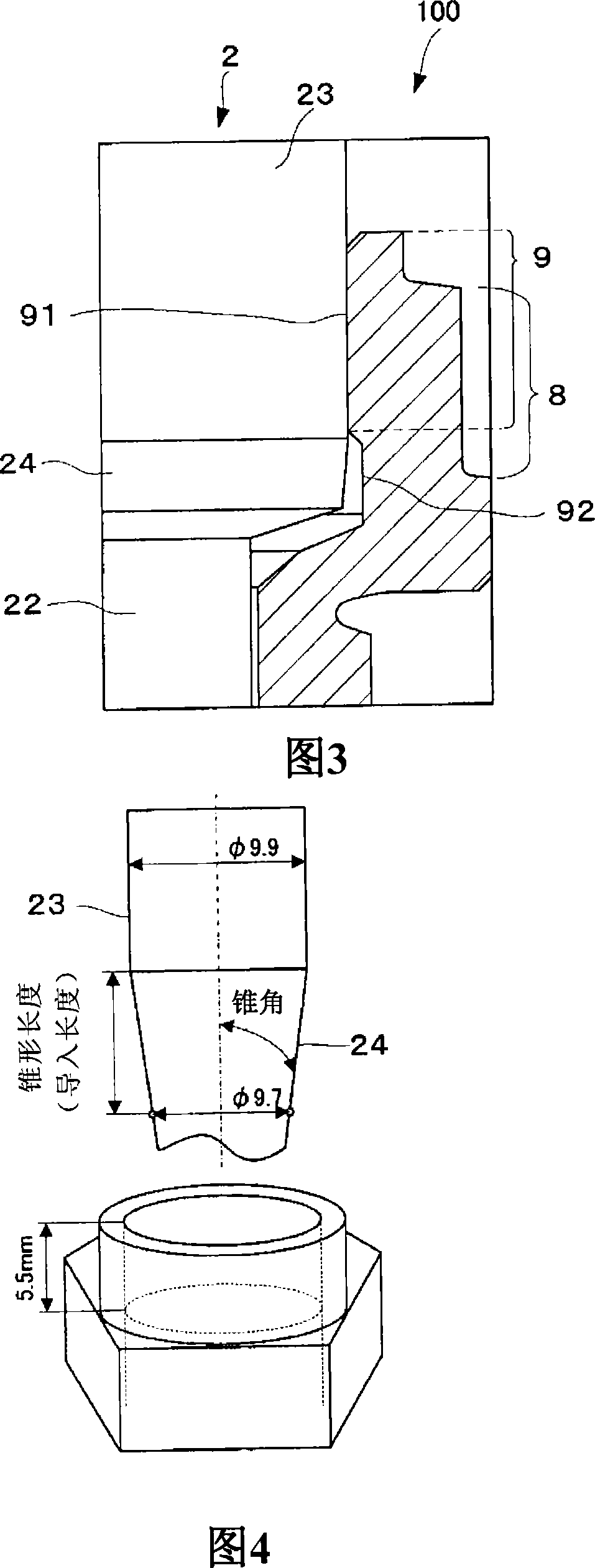

[0105] Embodiments of the present invention will be described below with reference to the drawings. FIG. 1 shows the state before the insulator is attached to the main body partner, and FIG. 2 shows the attached spark plug according to the embodiment of the present invention. The spark plug 100 has a substantially cylindrical metallic shell 1 and a substantially cylindrical insulator 2 in which a front end protrudes and fits into the metallic shell 1 . The center portion inside the insulator 2 is provided with the center electrode 3 along its axial direction, and is formed in a state where the front end portion of the center electrode 3 protrudes from the insulator 2 . Furthermore, a ground electrode 10 is provided facing the front end portion of the center electrode 3 . One end of the ground electrode 10 is combined with the main fitting 1 to form a spark discharge gap with a predetermined interval between the ground electrode 10 and the center electrode 3 .

[0106]The ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com