Corrugated board printing production line with environmental protection and energy saving functions

A corrugated cardboard, environmental protection and energy-saving technology, applied in printing, printing machines, rotary printing machines, etc., can solve the problems of increasing water consumption and power consumption for cleaning ink, increasing cleaning time of anilox rollers, and high consumption of water-based inks , to achieve the effect of saving ink consumption, saving labor costs, stable and quiet air suction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods. The orientation words used in the present invention all take the actual working state of the present invention as a reference.

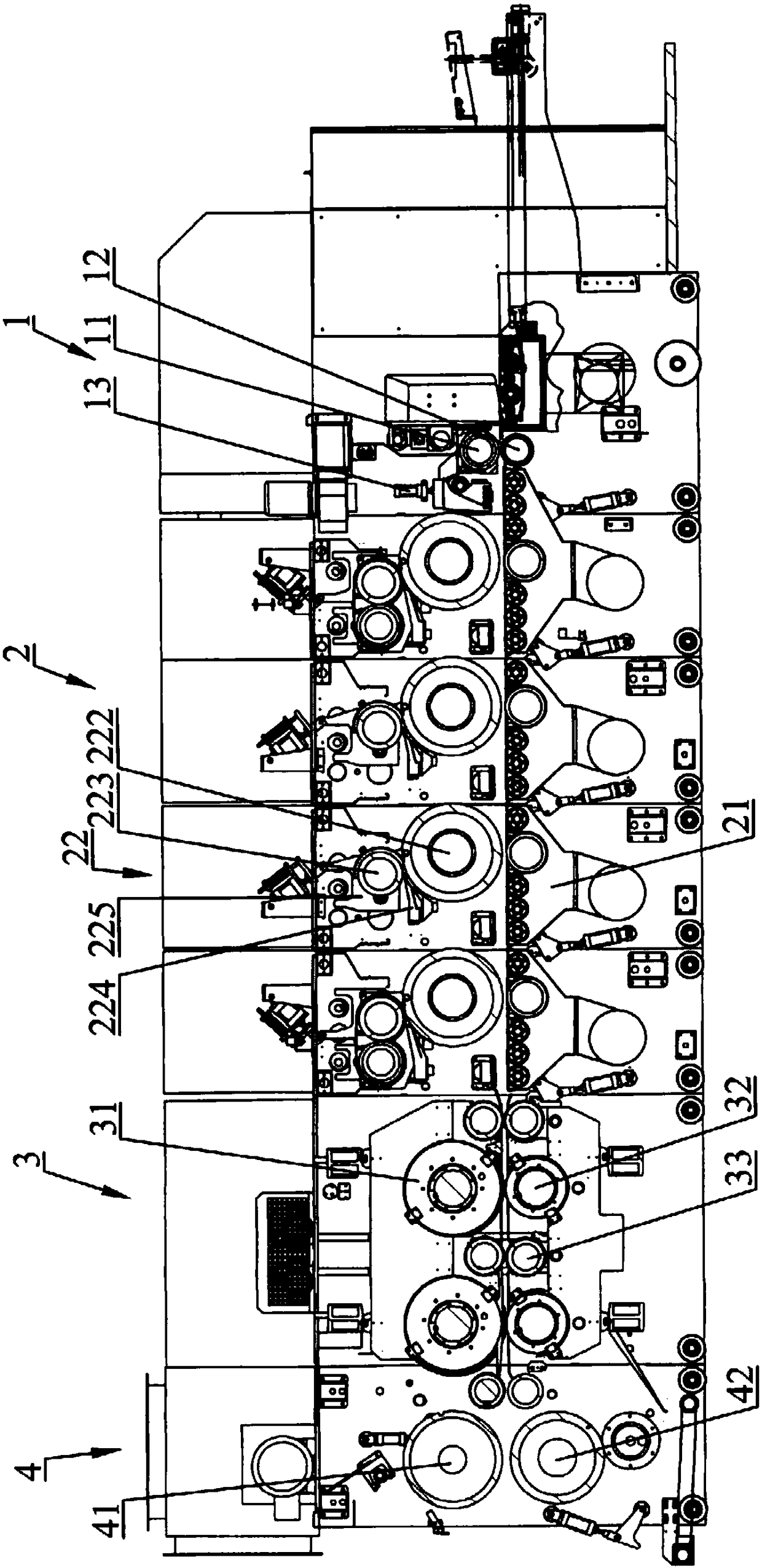

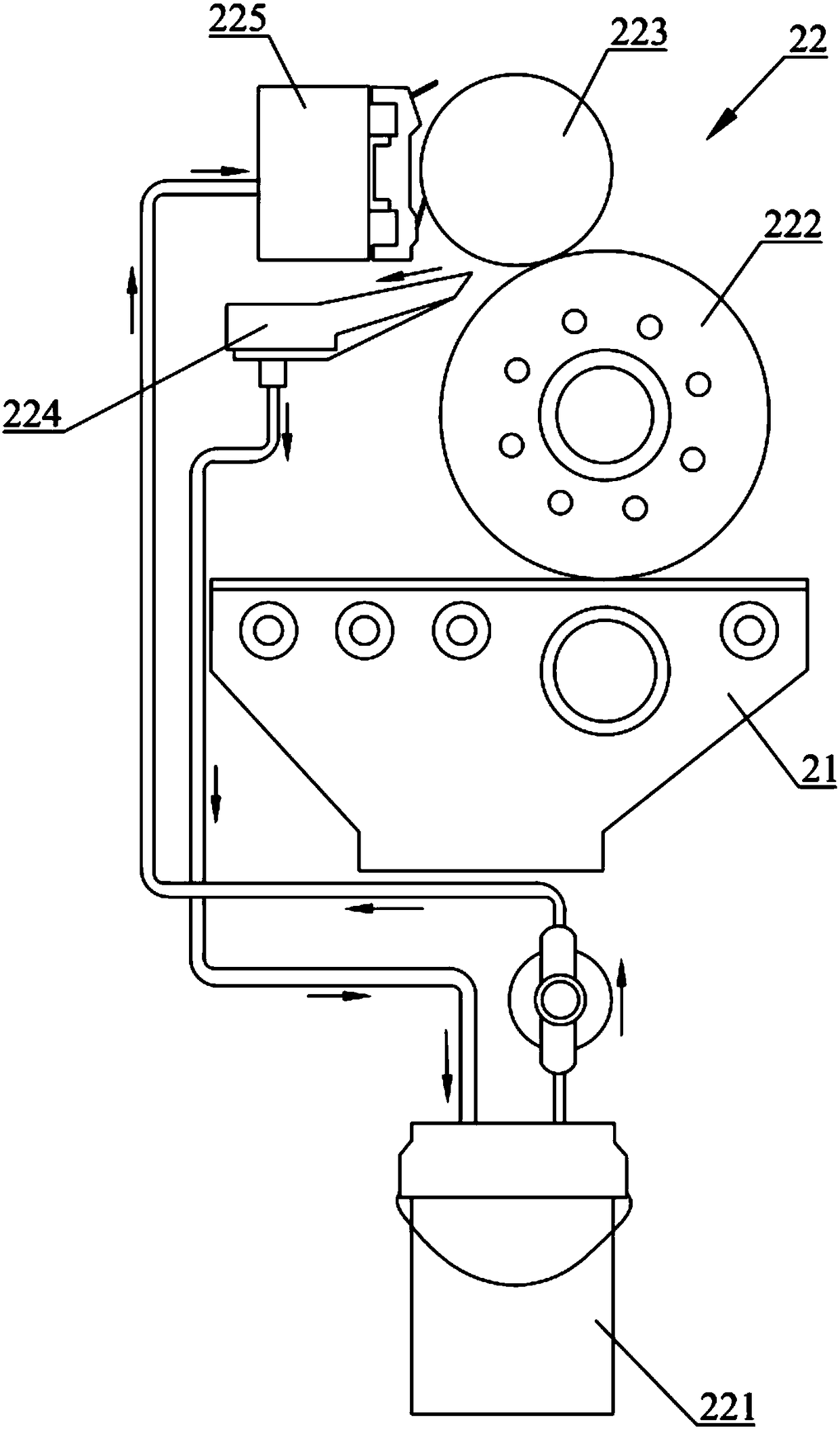

[0032] The invention provides a corrugated cardboard printing production line with environmental protection and energy saving functions, such as figure 1 As shown, the corrugated cardboard printing production line with environmental protection and energy saving functions includes a frame on which a paper feeding mechanism 1, a printing mechanism 2, a slotting mechanism 3, a die-cutting mechanism 4 and an automatic stacking mechanism are sequentially arranged along the moving direction of the corrugated cardboard. paper machine. In the present invention, the paper feeding mechanism 1, the printing mechanism 2, the slotting mechanism 3, the die-cutting mechanism 4 and the aut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com