Angle-variable universal joint pin body full-automatic tapping machine

A cross-axis, fully automatic technology, applied to metal processing machinery parts, other manufacturing equipment/tools, metal processing, etc., can solve problems such as low production efficiency and potential safety hazards, and achieve the effect of improving production efficiency and continuous processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

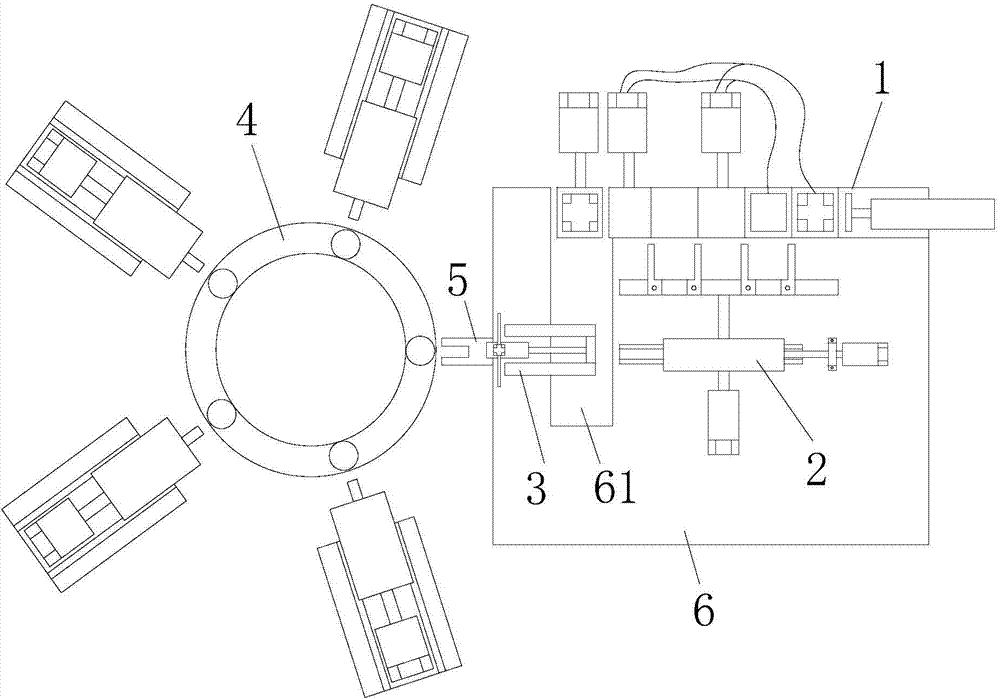

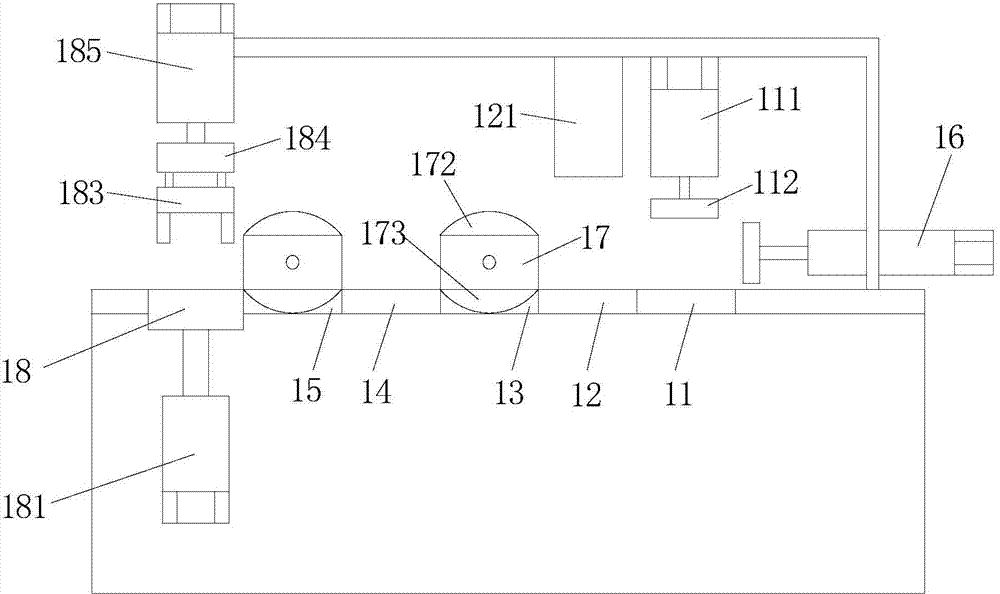

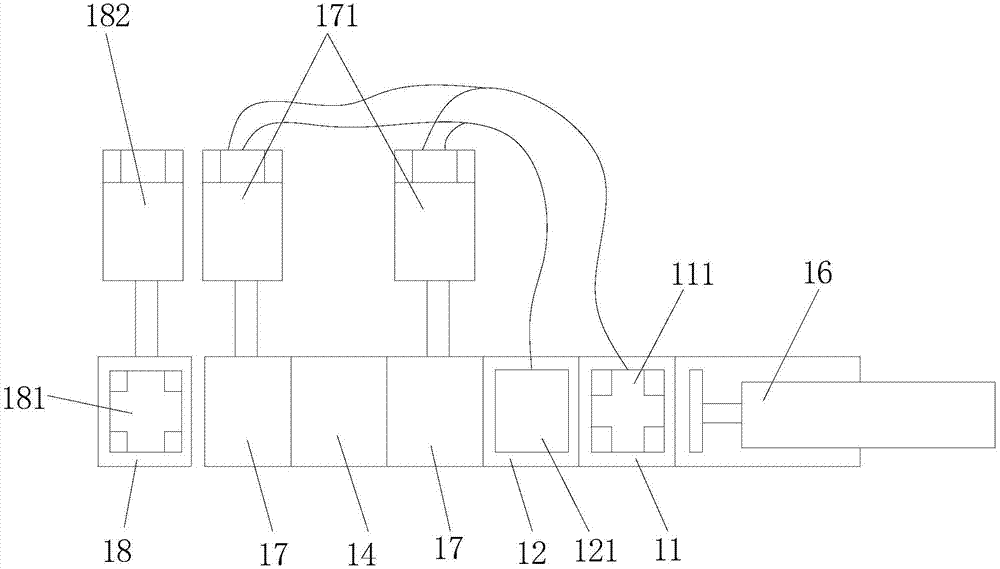

[0021] refer to Figure 1 to Figure 9 , a fully automatic tapping machine with a variable angle cross shaft body of the present invention, comprising a feeding device 1, a feeding device 2, a feeding device 3, a punching device 4 and a feeding device 5, the feeding device 1, the feeding device The device 2 and the feeding device 3 are installed on the processing platform 6, the punching device 4 and the unloading device 5 are located on one side of the feeding device 3, the unloading device 5 is located below the processing platform 6, and the feeding device 1 The first station 11, the second station 12, the third station 13, the fourth station 14 and the fifth station 15 are arranged in sequence on the upper side, and a first propulsion cylinder is installed on one side of the first station 11. 16. A detection device 111 is installed above the first station 11, the upper end of the detection device 111 is connected to the first lift cylinder 112, a CCD detection camera 121 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com