Short-distance pipeline inner wall bionic groove surface machining device and method

A surface processing and short-distance technology, which is applied to the field of bionic groove surface processing devices on the inner wall of short-distance pipelines, can solve problems such as unfavorable daily operation management, insignificant economic benefits, and toxicity of drag reducing agents, and achieves compact structure design, pipe Wide diameter range and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

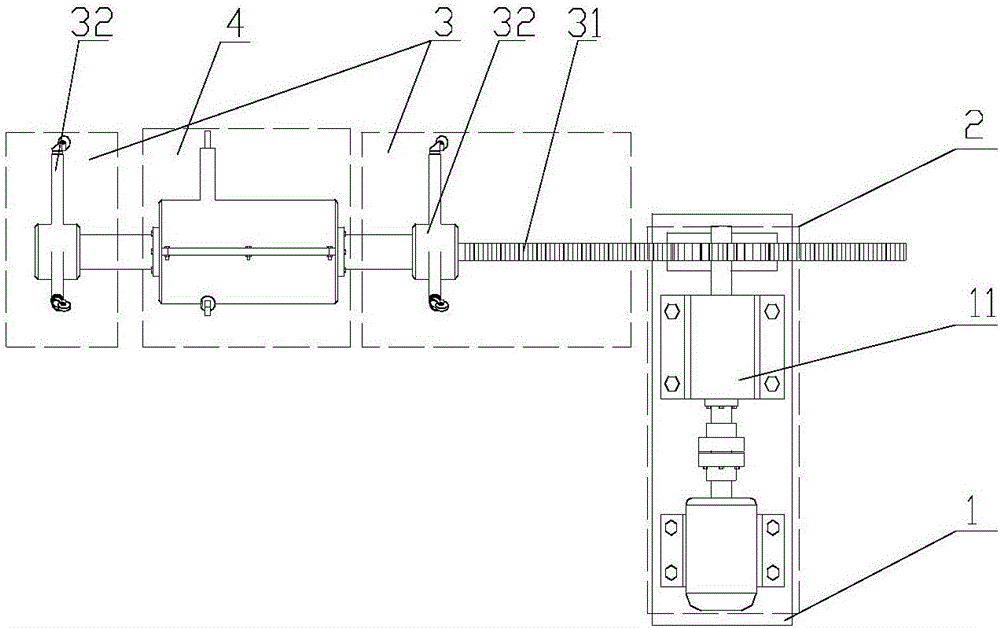

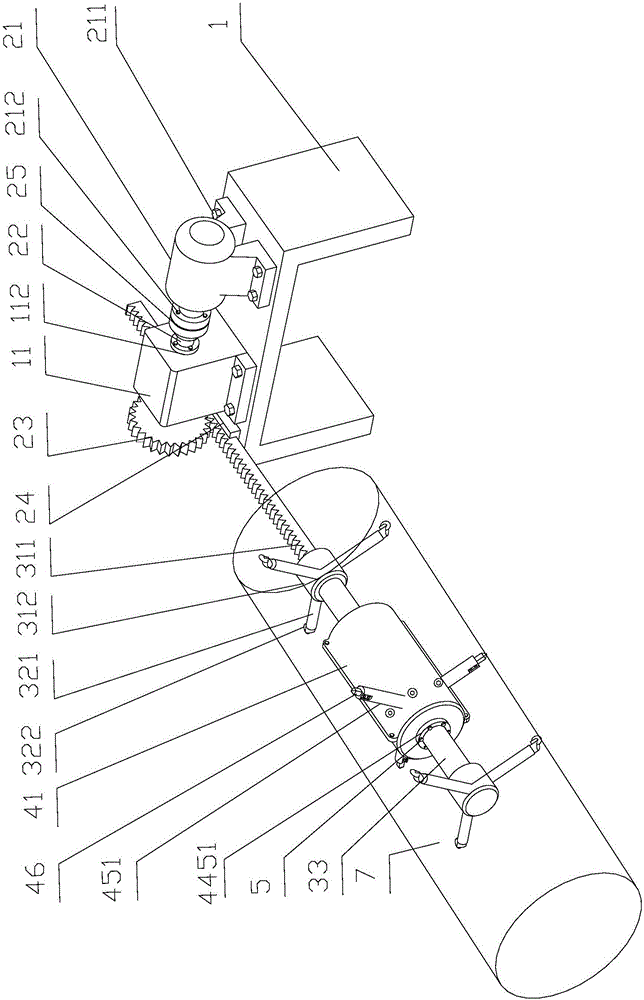

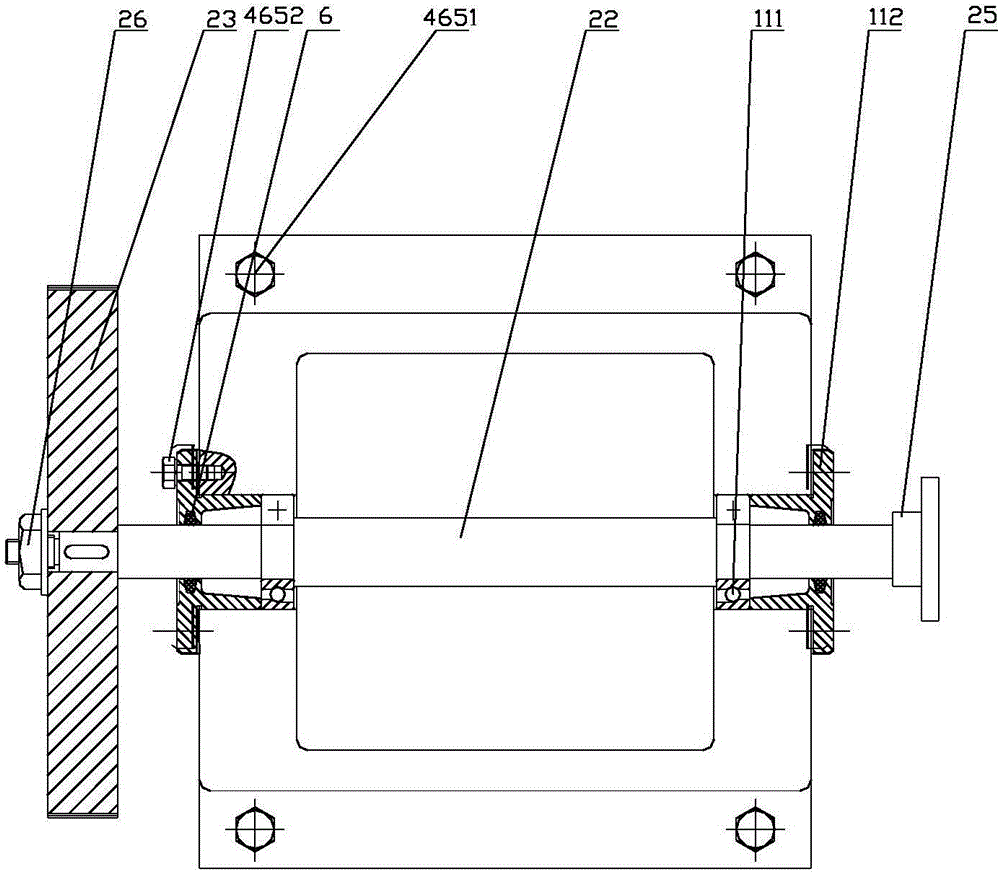

[0051] Embodiment 2 Utilizes the processing method of a short-distance pipeline inner wall bionic groove surface processing device described in Embodiment 1, including the following steps:

[0052] 1) According to the diameter of the pipe to be processed, rotate and adjust each walking frame of the front and rear traveling mechanisms to make it extend radially until each universal pulley at the top of the walking frame can just withstand the inner wall of the pipe, so that the processing device enters the pipe Part of the internal operation is balanced to ensure its stability;

[0053] 2) placing the bionic groove surface processing device on the inner wall of the pipeline in the pipeline 7 to be processed;

[0054]3) Start the executive motor 21, drive the gear 23 to rotate, realize the axial movement of the rack section 311 along the guide rail 24 by 80 mm, and then the front and rear traveling units support the processing part and move forward by 80 mm, so that the travelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com