Pipe end hydraulic forming device for automobile pipe

A technology of hydroforming and pipe fittings, which is applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc. It can solve the problems that the mold core and mold sleeve cannot be replaced according to the needs, continuous processing cannot be realized, and one machine cannot be used for multiple purposes. Uniformity, increased compressive strength, and improved machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

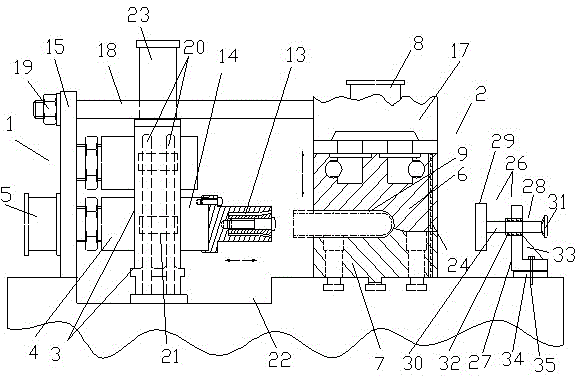

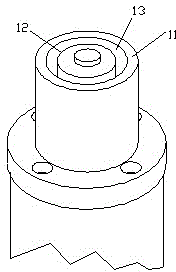

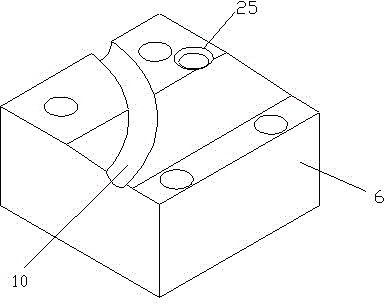

[0022] refer to figure 1 , figure 2 , image 3 , propose an embodiment of the present invention, this embodiment includes the hydraulic mold 1 that is arranged on the workbench, clamping mold 2, described hydraulic mold includes mold base 3, mold column 4, hydraulic oil cylinder 5, mold column 4 can shaft Slidingly placed on the mold base 3, the piston rod of the hydraulic cylinder 5 is connected with the mold column 4; the clamping mold 2 includes the upper module 6, the lower module 7, the clamping hydraulic cylinder 8, the upper module 6 and the clamping hydraulic cylinder The 8 piston rods are connected, and the upper module 6 and the lower module 7 are respectively provided with an upper clamping groove 9 and a lower clamping groove 10 adapted to the shape of the pipe to be processed. Described against die 26 comprises base 27, against column 28, and vertical plate of base 27, horizontal plate intersect vertically and is " L " or inverted " T " shape, and the vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com