Method and device for machining tooth profile of inner gear with drum-shaped worm tool

A drum-shaped worm and internal gear technology, applied in the direction of gear teeth, elements with teeth, belts/chains/gears, etc., can solve the problems that internal gears and worms are impossible and have no effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

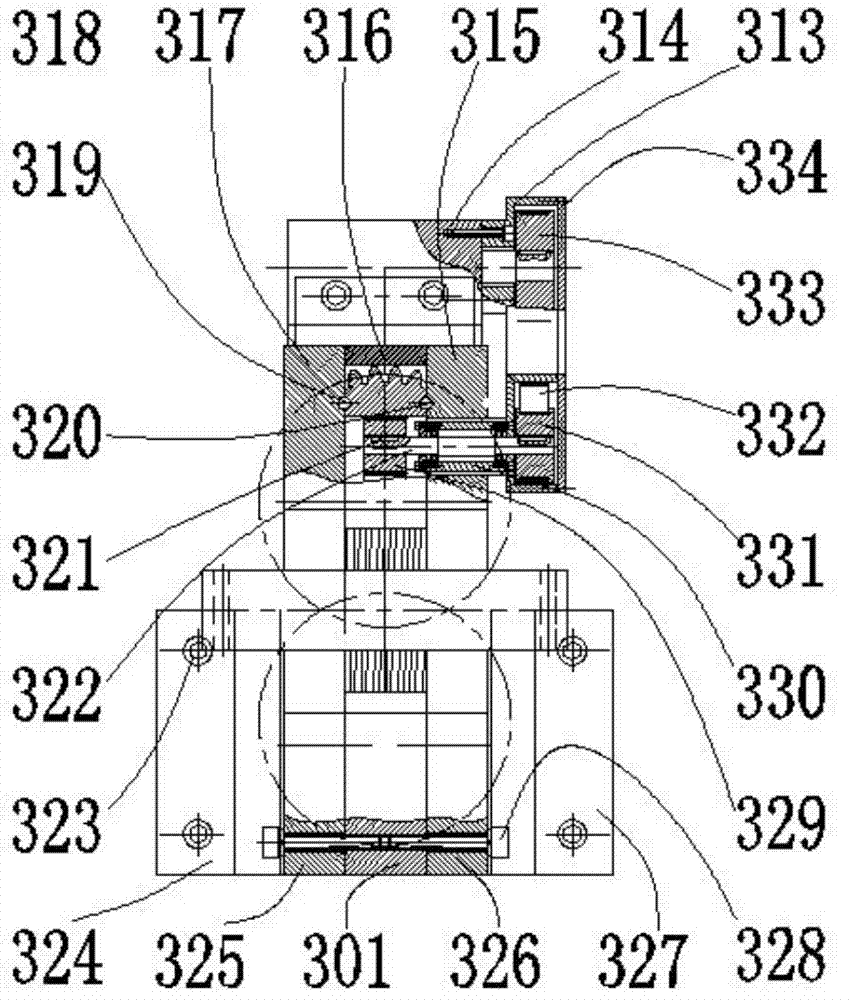

[0039] The present invention includes a method and apparatus for machining the tooth profile of an internal gear using a drum worm tool.

[0040] Among them, including a method of machining the tooth profile of an internal gear using a drum-shaped worm tool, see Figure 1a , 1b , 1c, 2a, 2b, 2c. The specific steps of the method are as follows:

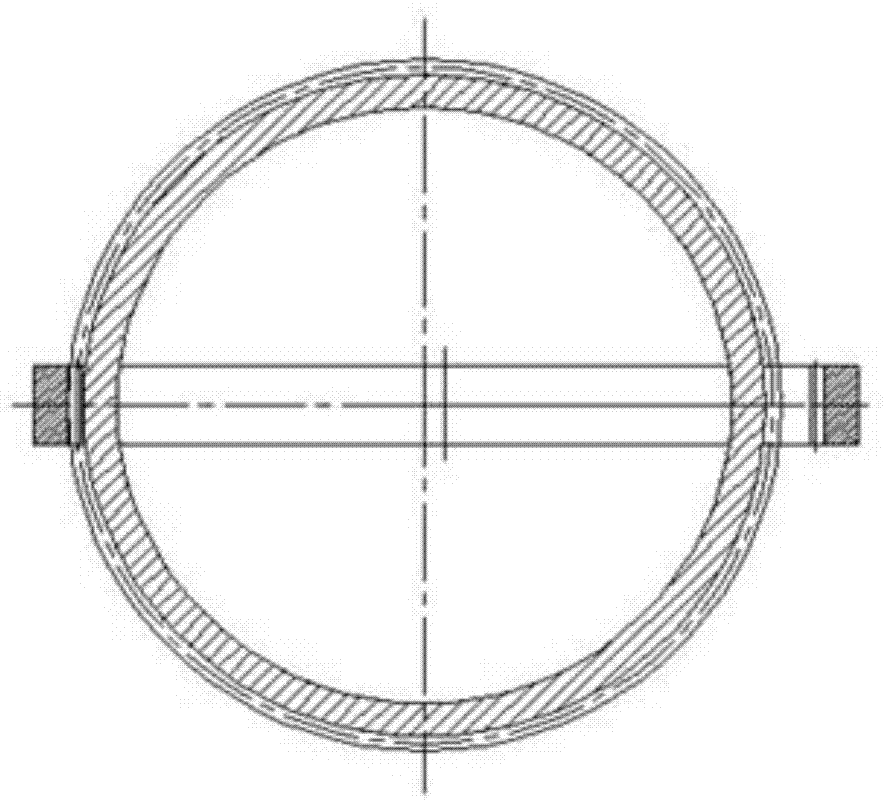

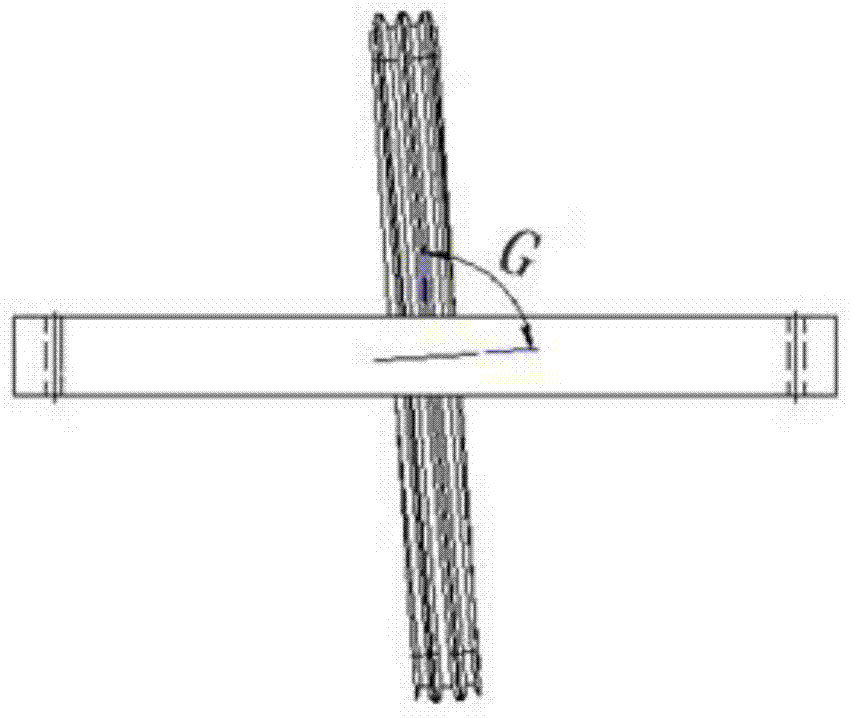

[0041] Step 1: Design a flat or short drum-shaped worm tool, such as Figure 1c as shown in item 02 or Figure 2c Shown in 02'. The worm grinding wheel can be made as a single-head or multi-head worm, and the worm is located on an annulus, and the radius of the parent circle of the annulus is Figure 1c or Figure 2c The pitch circle radius R0 of the imaginary gears C1 and C2 in . In the figure, the cross-sectional shape of the gear teeth on C2 is the shape obtained by rotating the cross-section on C1 by half the pitch angle (when the worm is a single-head worm) or multiple half-pitch angles equal to the number of worm heads. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com