A buckling-resistant brace arranged crosswise, a building with the brace and its application

An anti-buckling bracing and cross-arrangement technology, which is applied to building components, shockproof, etc., can solve the problems of reducing energy dissipation capacity, increasing outer sleeve, and wasting steel, achieving good durability and hysteretic performance, facilitating structural optimization, The effect of component weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

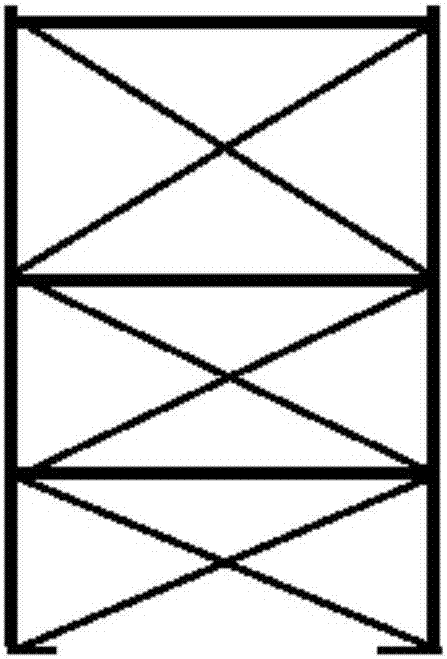

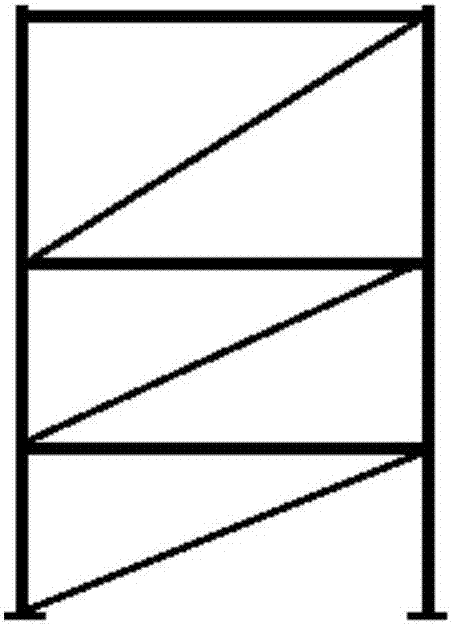

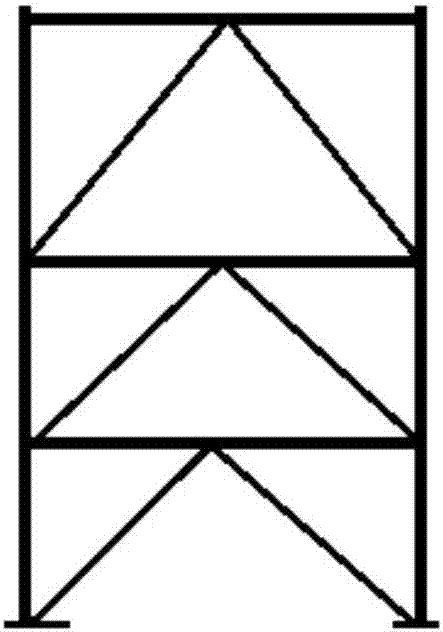

[0053] Embodiment: A cross-arranged anti-buckling support, including a first force-bearing member and a second force-bearing member; both force-bearing members have a force-bearing main pipe 1, and the middle sections of the two force-bearing main pipes 1 have a protrusion 7; The inner side of the protruding part 7 of the stressed main pipe 1 is fixedly connected with the inner restraint sleeve 3, and the outer side is fixedly connected with the outer restraint sleeve 2; the inner and outer restraint sleeves cooperate to prevent the overall buckling and / or local buckling of the stressed main tube 1. The two stressed main pipes 1 are connected by welding, and the axes form an X-shaped structure. According to different needs, the two stress-bearing main pipes 1 can be selected as square or circular closed hollow structures at the same time.

[0054] The length and the increased cross-sectional area of the protruding portion 7 of the stressed main pipe 1 are determined accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com