An insulating type aerial work vehicle double working bucket device and its working method

A technology for aerial work vehicles and working buckets, which is applied in the direction of electromechanical devices, lifting devices, lifting equipment safety devices, etc., can solve the problems of small carrying capacity, only one working bucket, limited operating flexibility, etc., and achieve structural stress Reasonable, large operating range, large rotation range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0050] Example.

[0051] see Figure 1 to Figure 16 .

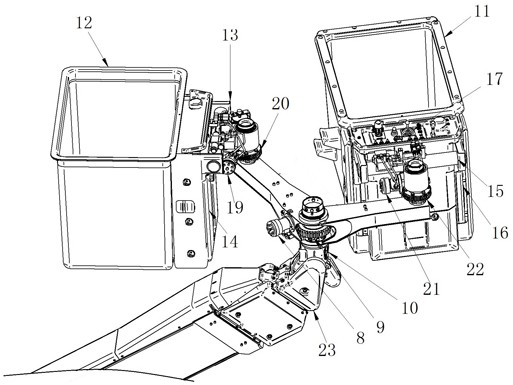

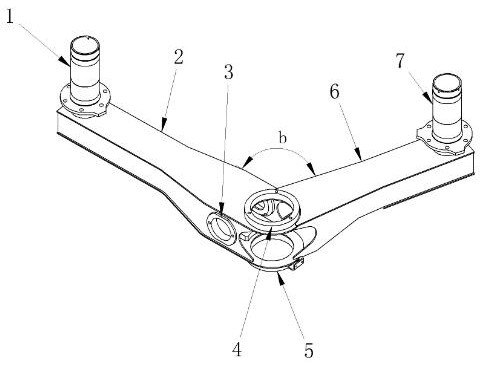

[0052] This embodiment discloses an insulated aerial work vehicle double working bucket device, including a column 10, a special-shaped rotating arm, a left working bucket 12, a right working bucket 11 and a double working bucket anti-interference device. The vertical column 10 is installed on the aerial work vehicle At the end of the working arm 23, the special-shaped turning arm can be installed on the column 10 in a horizontal plane.

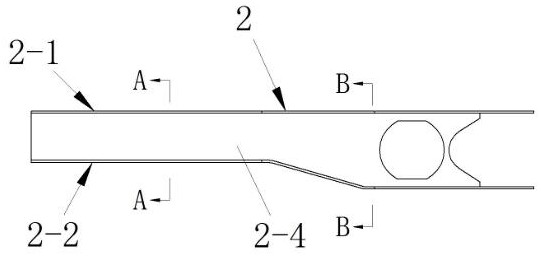

[0053] In this embodiment, the special-shaped pivoting arm includes a left pivoting arm frame 2 and a right pivoting arm frame 6, there is an angle between the left pivoting arm frame 2 and the right pivoting arm frame 6, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com