Photosynthesis bioreactor system for industrial production of micro algae

A reactor system and photosynthetic biology technology, applied in the direction of photobioreactor, specific-purpose bioreactor/fermenter, bioreactor/fermenter combination, etc., can solve the problems of inability to produce large water body, aging collapse, The internal temperature of the closed-circuit pipeline is difficult to control and other problems, so as to prevent the infection of foreign organisms and various chemical pollution factors, increase the biological productivity and output, and improve the efficiency of photosynthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

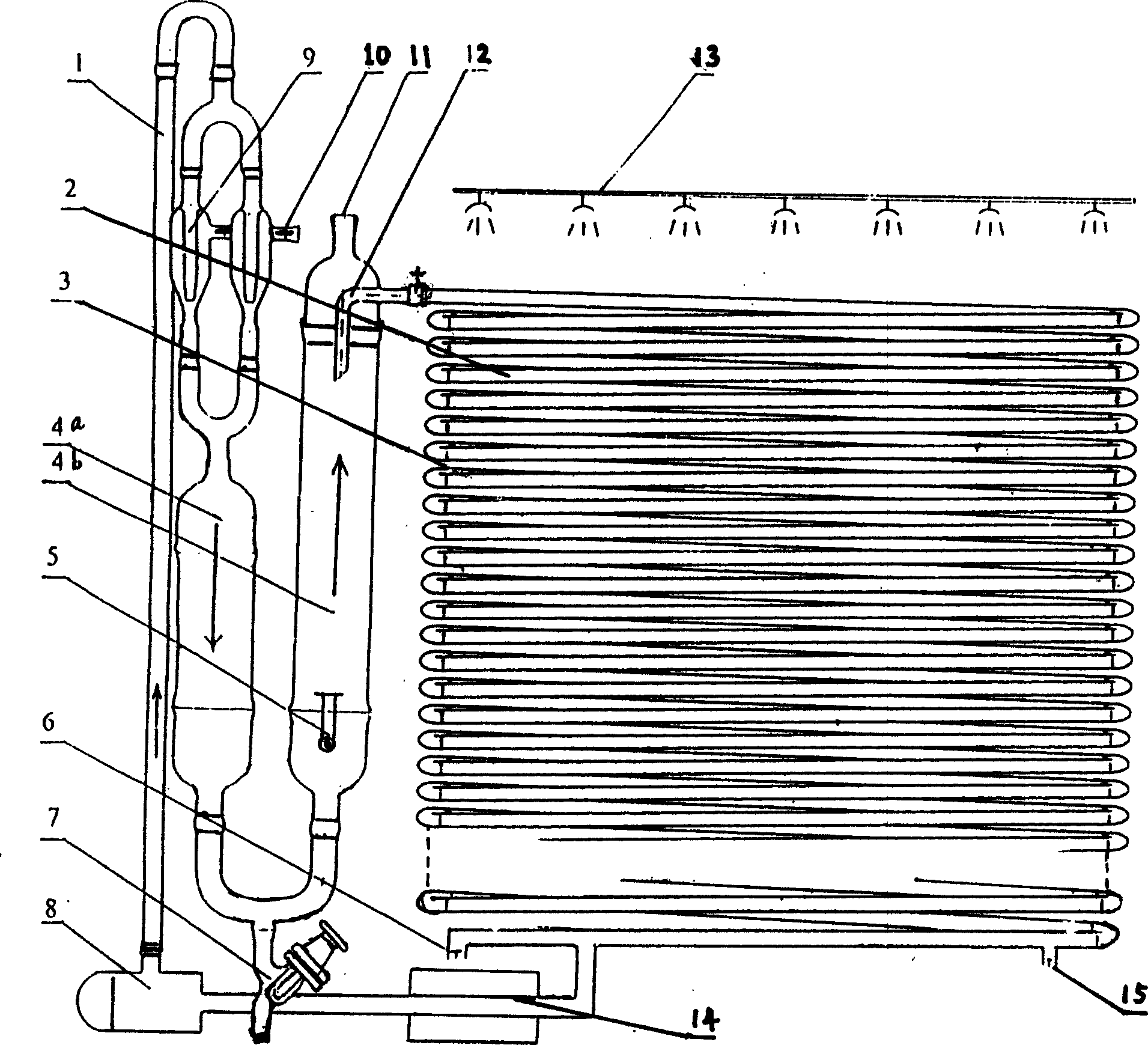

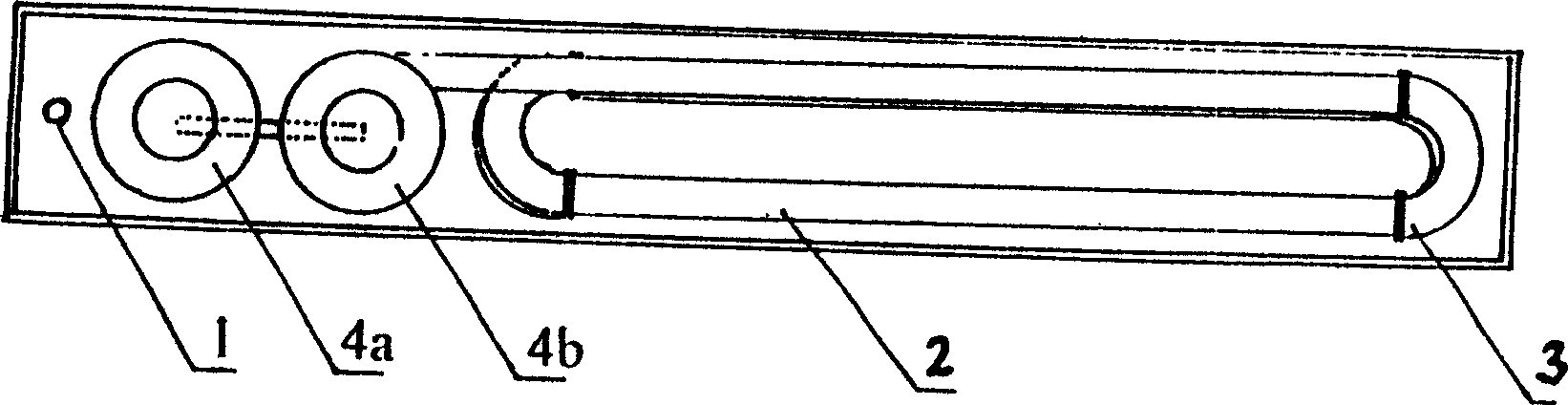

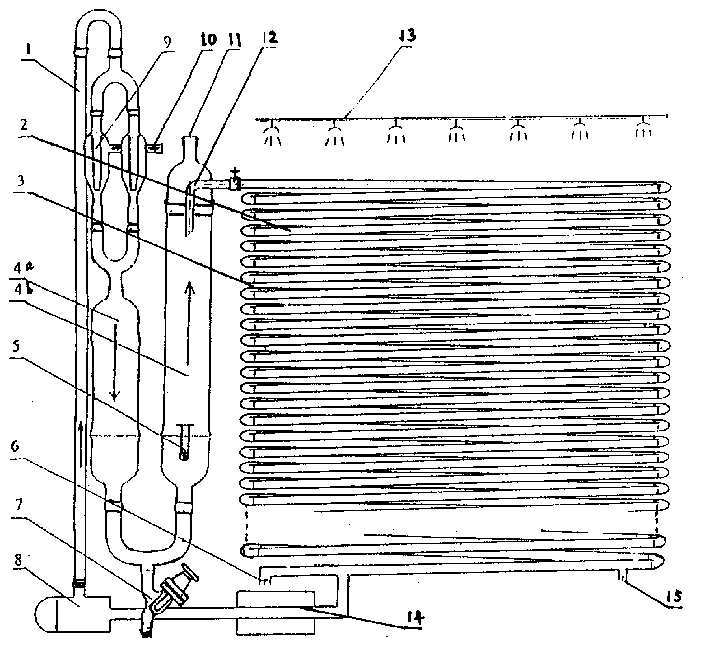

[0034] Embodiment 1 A photosynthetic bioreactor system for industrialized production of microalgae, comprising a reaction tower, microalgae photosynthetic bioreaction pipeline device 2, infusion pump 8, carbon dioxide gas injection device, artificial lighting device 13, cold and heat exchanger 14, infusion Pipe 1, the reaction tower adopts a parallel and upright double-tower structure, and the upper part of the oxygen exhaust reaction tower 4a is provided with a negative pressure pump 9, and the side of the negative pressure pump 9 is provided with an oxygen exhaust port 10, and the middle part of the oxygen exhaust reaction tower 4a is a cavity, and the exhaust The lower part of the oxygen reaction tower 4a is connected to the lower part of the control reaction tower 4b, and a reactant sampling valve 7 is also provided at the connection. The upper port of the biological reaction pipeline device 2 is connected, the upper part of the control reaction tower 4b is also provided wi...

Embodiment 2

[0036] A photosynthetic bioreactor system for the industrial production of microalgae. The microalgae photosynthetic bioreactor pipeline device 2 adopts a three-dimensional double-row flat spiral pipeline device, wherein the unit parts of each layer of the three-dimensional double-row flat spiral pipeline device are straight tubes. U-shaped connecting elbow 3 is connected; the oxygen exhaust reaction tower 4a, the control reaction tower 4b and the microalgae photosynthetic biological reaction pipeline device 2 are made of high light-transmitting glass materials. The infusion pump 8 is driven by zero-shear force culture fluid; the upper part of the oxygen exhaust reaction tower 4a adopts a dual-channel double negative pressure pump 9 structure, and the side of the dual channel double negative pressure pump 9 is provided with an oxygen exhaust port 10 .

[0037] All the other structures are as in Example 1.

[0038] Its operation process is as follows: a zero-shear force culture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com