Three section laminar flow cooling technology for hot rolling band steel

A cooling process, hot-rolled strip technology, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve problems such as easy deformation, steel spread accident, steel jam accident, etc., and achieve improved performance uniformity and uniform performance. The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

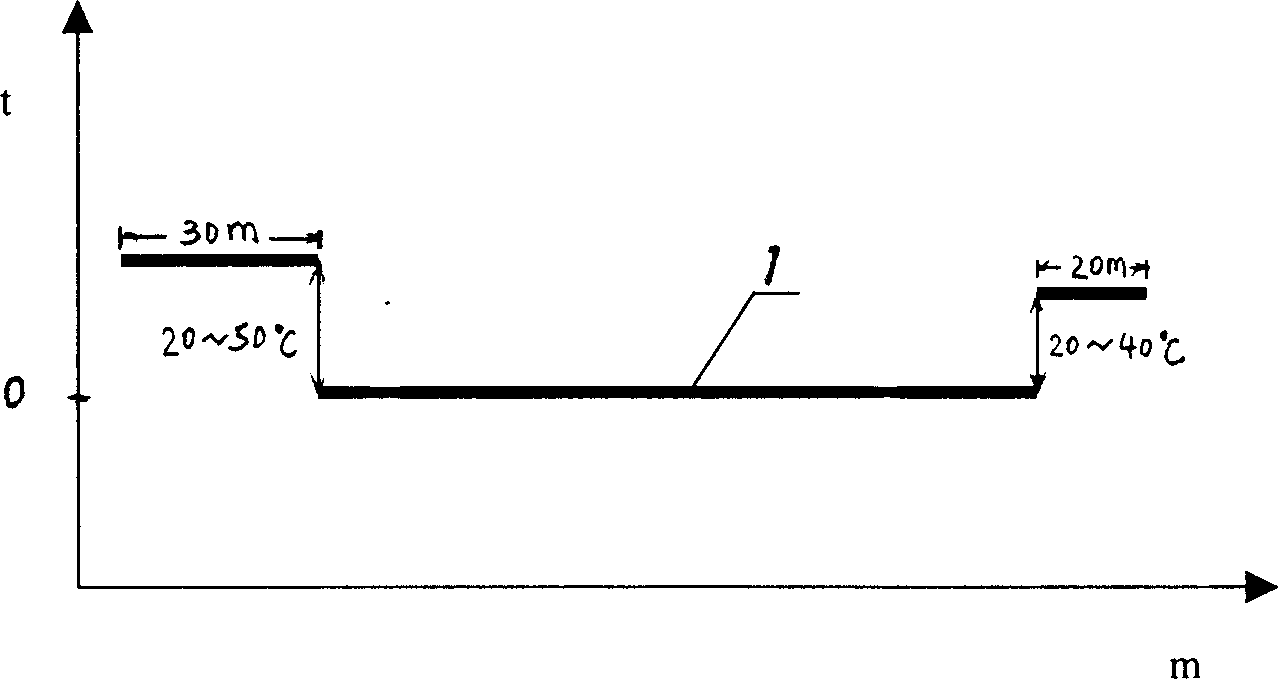

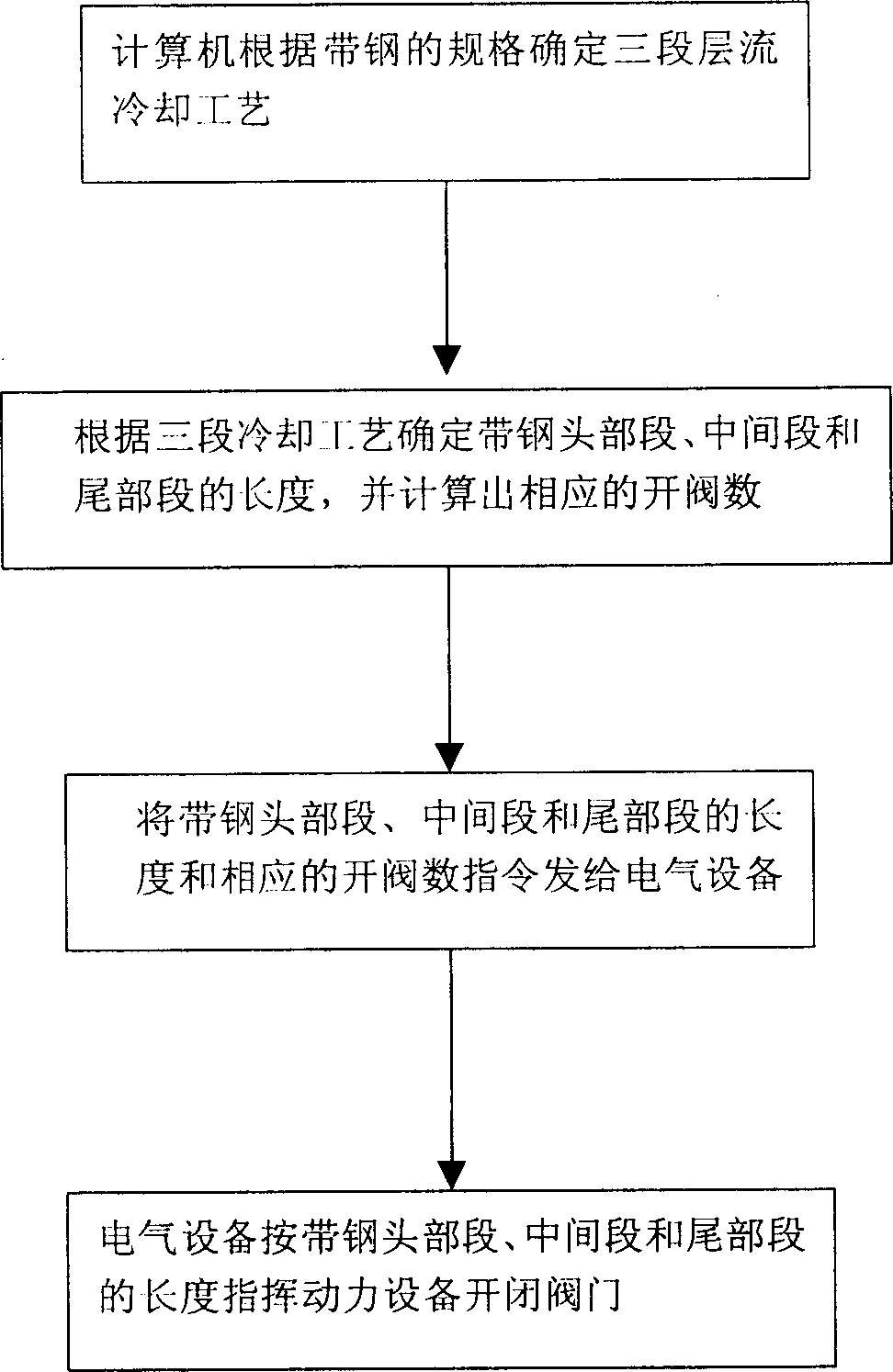

[0015] Embodiment 1 of the present invention takes the strip steel of SS400 steel production 1.5 * 1250mm specification as example, and the target coiling temperature of strip steel 1 is set as 650 ℃, can see that the ideal coiling temperature of its head segment should be greater than The target coiling temperature is 35°C, that is, 685°C, while the coiling temperature of the tail section should be 675°C. According to the three-stage cooling control program (see attached Figure 4 ), first check whether it is three-stage cooling; if so, then determine the three-stage cooling process system (find out the difference between the head section and the tail section and the target coiling temperature); calculate the number of valve openings in the three sections (the layer of the head section The number of flow valves is 6, the middle section is 9, and the tail section is 7), and the respective lengths are determined. Then the electrical equipment directs the power equipment to ope...

Embodiment 2

[0017] Embodiment 2 of the present invention takes Q345A steel to produce strip steel of 16×1550mm specification as an example, the target coiling temperature of strip steel 1 is set at 630°C, and it can be seen from Table 1 that the ideal coiling temperature of the head section should be greater than the target The coiling temperature is 50°C, that is, 680°C, and the coiling temperature of the tail section should be 670°C. According to the three-stage cooling control program, the computer calculates that the number of laminar flow valves in the head section of strip 1 is 28, that in the middle section is 36, and that in the tail section is 30. Finally, the power equipment completes the opening and closing of the valve according to the above-mentioned different valve numbers, thereby realizing the three-stage laminar flow cooling process of the hot-rolled strip steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com