Method for preparing carbon nanotube on glass substrates

A carbon nanotube and glass substrate technology, applied in the field of carbon nanotube field emission cathode preparation, can solve the problems of poor quality, unsatisfactory emission current size and emission uniformity, limiting practical application, etc. The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

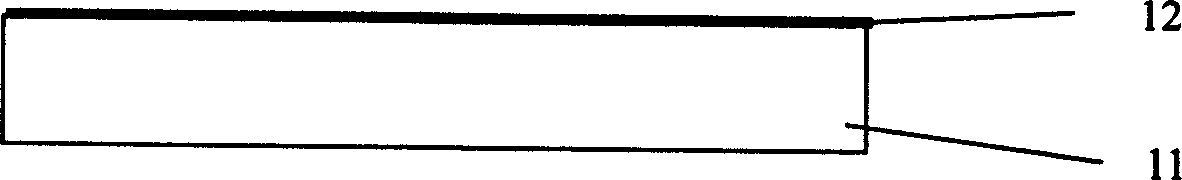

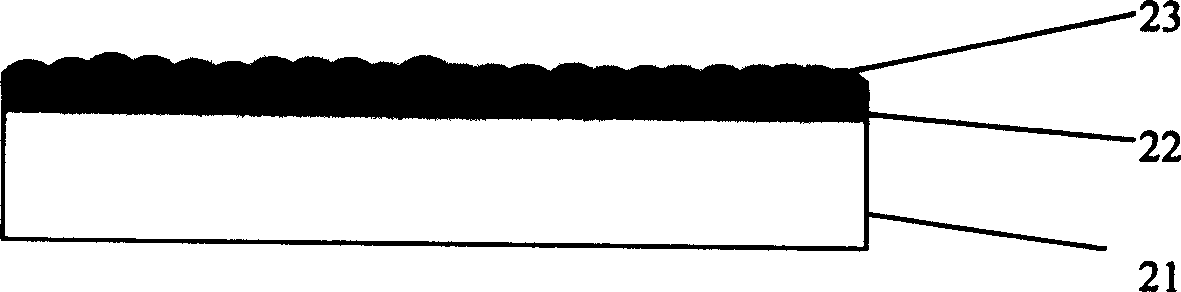

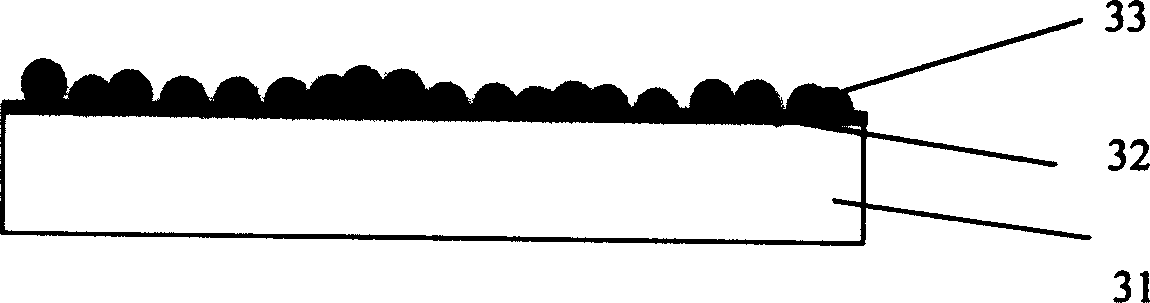

Image

Examples

Embodiment 1

[0016] The substrate is ordinary window glass, on which a calcium fluoride film with a thickness of 100 nanometers is deposited by electron beam evaporation, and then a nickel film with a thickness of about 10 nanometers is deposited, which is prepared by thermal decomposition chemical vapor deposition in a vacuum system carbon nanotubes. Acetylene is used as the gas, the pressure is about 100 Pa, and the substrate temperature is 400 degrees to obtain carbon nanotubes of good quality, and the substrate glass has no sign of softening.

Embodiment 2

[0018] The substrate is ordinary window glass, on which a layer of neodymium fluoride film with a thickness of 50 nanometers is deposited by electron beam evaporation method, and then a layer of nickel film with a thickness of about 20 nanometers is deposited, which is prepared by thermal decomposition chemical vapor deposition in a vacuum system carbon nanotubes. Acetylene is used as the gas, the pressure is about 100 Pa, and the substrate temperature is 500 degrees to obtain carbon nanotubes of good quality, and the substrate glass has no sign of softening.

Embodiment 3

[0020] The substrate is made of glass with a high softening point, on which a magnesium fluoride film with a thickness of 500 nanometers is deposited by electron beam evaporation, and then a layer of iron film with a thickness of about 100 nanometers is deposited. Preparation of carbon nanotubes. Acetylene was used as the gas, the pressure was about 200 Pa, and the substrate temperature was 650°C. Good quality carbon nanotubes were obtained, and the substrate glass showed no sign of softening.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com