Preparation method and application of two-dimensional lithium metal

A technology of metal lithium and compression method, which is applied in metal rolling, electrode manufacturing, electrode forming, etc., can solve the problems of battery fire and coulombic efficiency reduction, improve cycle life, solve lithium dendrite growth problems, and suppress unevenness The effect of sedimentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] First, put the metal lithium sheet with a thickness of 1-2 mm into a glove box filled with argon, and compress and deform the metal lithium sheet under the pressure of the indenter, and the deformation amount is 30%;

[0025] In the glove box, the metal lithium sheet is compressed and deformed by the pressure of the indenter, and the deformation is 30%;

[0026] Repeat steps (1) and (2) until the thickness of the lithium metal sheet reaches below 20 microns to obtain a two-dimensional lithium metal sheet;

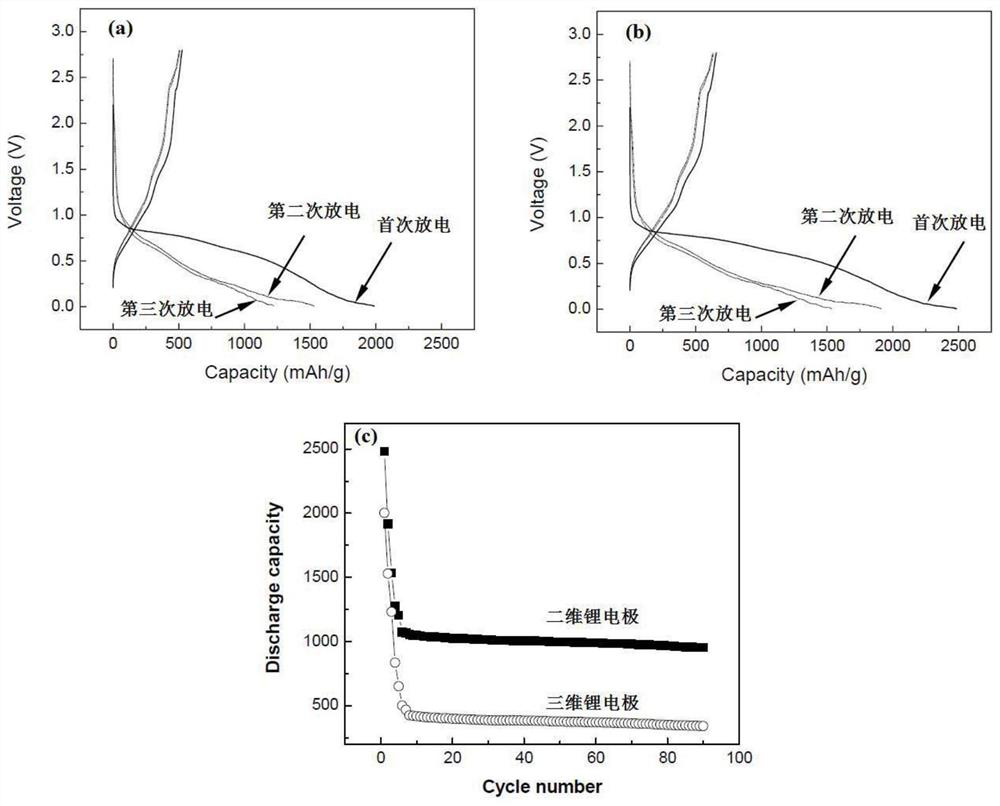

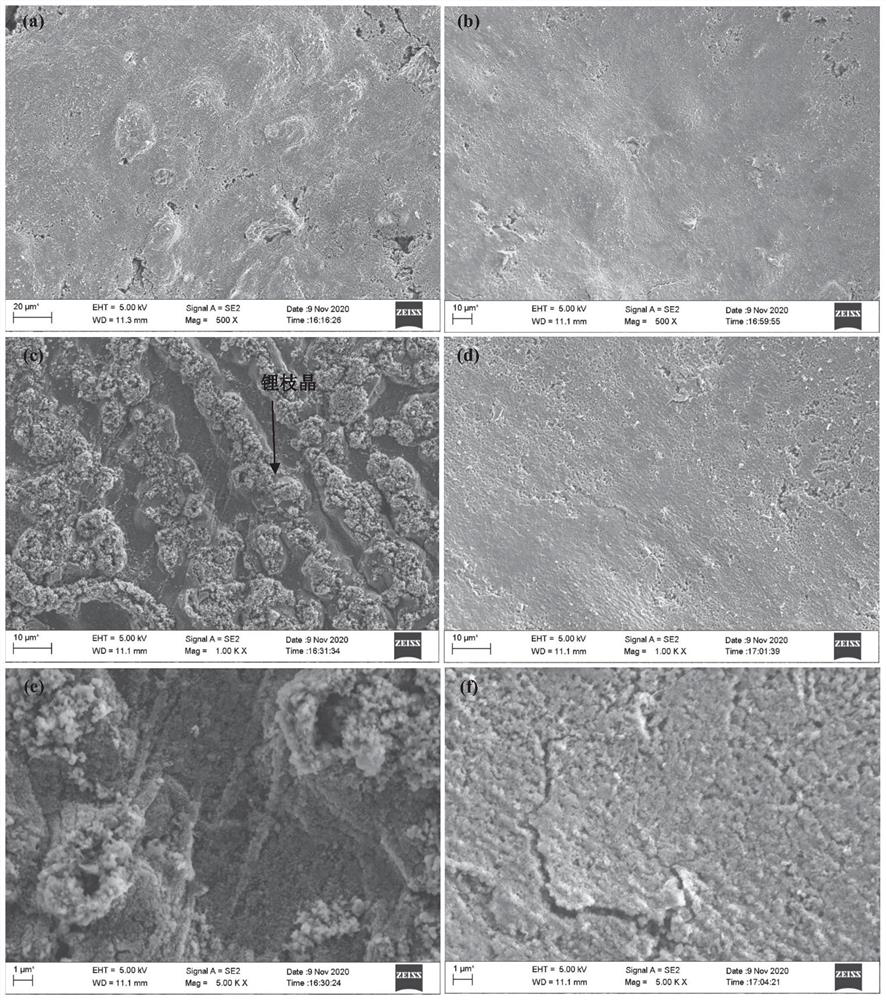

[0027] The two-dimensional metal lithium sheet is used as the negative electrode, the manganese oxide is used as the positive electrode, and Li-O 2 Battery. Test Results figure 1 As shown in (b), the discharge capacity (800-950mAh / g) of the two-dimensional metal lithium electrode is significantly higher than that of the three-dimensional metal lithium electrode (300-400mAh / g), and the cycle life is significantly improved. The scanning electron microscope images of...

Embodiment 2

[0029] (1) First put the metal lithium sheet with a thickness of 1 to 2 mm into a glove box filled with argon, and compress and deform the metal lithium sheet through the pressure of the indenter in the metal mold, and the deformation amount is 30%;

[0030] (2) In the glove box, the metal lithium sheet is compressed and deformed by the pressure of the indenter in the metal mold, and the deformation is 30%;

[0031] (3) Repeat steps (1) and (2) until the thickness of the lithium metal sheet reaches below 20 microns to obtain a two-dimensional lithium metal sheet;

[0032] (4) Assemble a lithium-sulfur battery with a two-dimensional metal lithium sheet as the negative electrode and elemental sulfur as the positive electrode.

[0033] The discharge capacity (600-800mAh / g) of the two-dimensional metal lithium electrode is obviously higher than that of the three-dimensional metal lithium electrode (300-400mAh / g), and the cycle life is obviously improved.

Embodiment 3

[0035] (1) First put the lithium metal sheet with a thickness of 1 to 2mm into a glove box filled with argon, and compress and deform the lithium metal sheet under the pressure of the roll, and the deformation amount is 30%;

[0036] (2) In the glove box, the metal lithium sheet is compressed and deformed by the pressure of the roll, and the amount of deformation is 30%;

[0037] (3) Repeat steps (1) and (2) until the thickness of the lithium metal sheet reaches below 20 microns to obtain a two-dimensional lithium metal sheet;

[0038] (4) Assemble a lithium-sulfur battery with a two-dimensional metal lithium sheet as the negative electrode and elemental sulfur as the positive electrode.

[0039] The discharge capacity (650-800mAh / g) of the two-dimensional metal lithium electrode is obviously higher than that of the three-dimensional metal lithium electrode (300-400mAh / g), and the cycle life is obviously improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com