Slow-release chlorine dioxide air purification gel and preparation method thereof

A technology of air purification gel and chlorine dioxide, which is applied in chemical instruments and methods, botanical equipment and methods, separation methods, etc., can solve the problem of poor gel effect, poor control of poured water, and bacteria Insufficient killing effect and other problems, to achieve long-lasting disinfection effect, good bactericidal effect, and good gel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

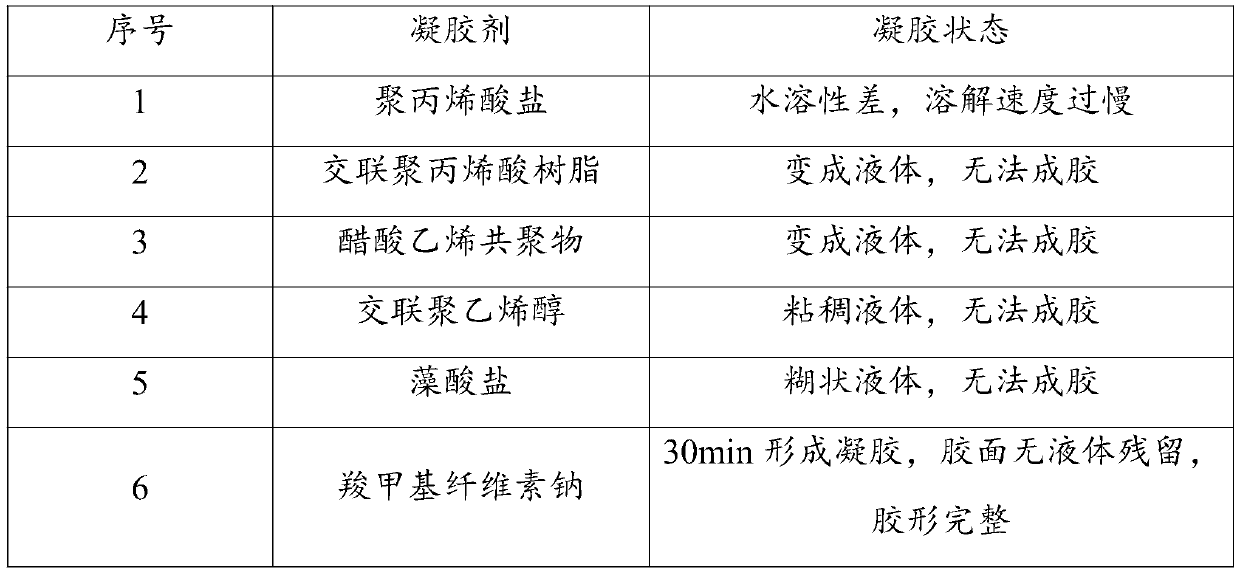

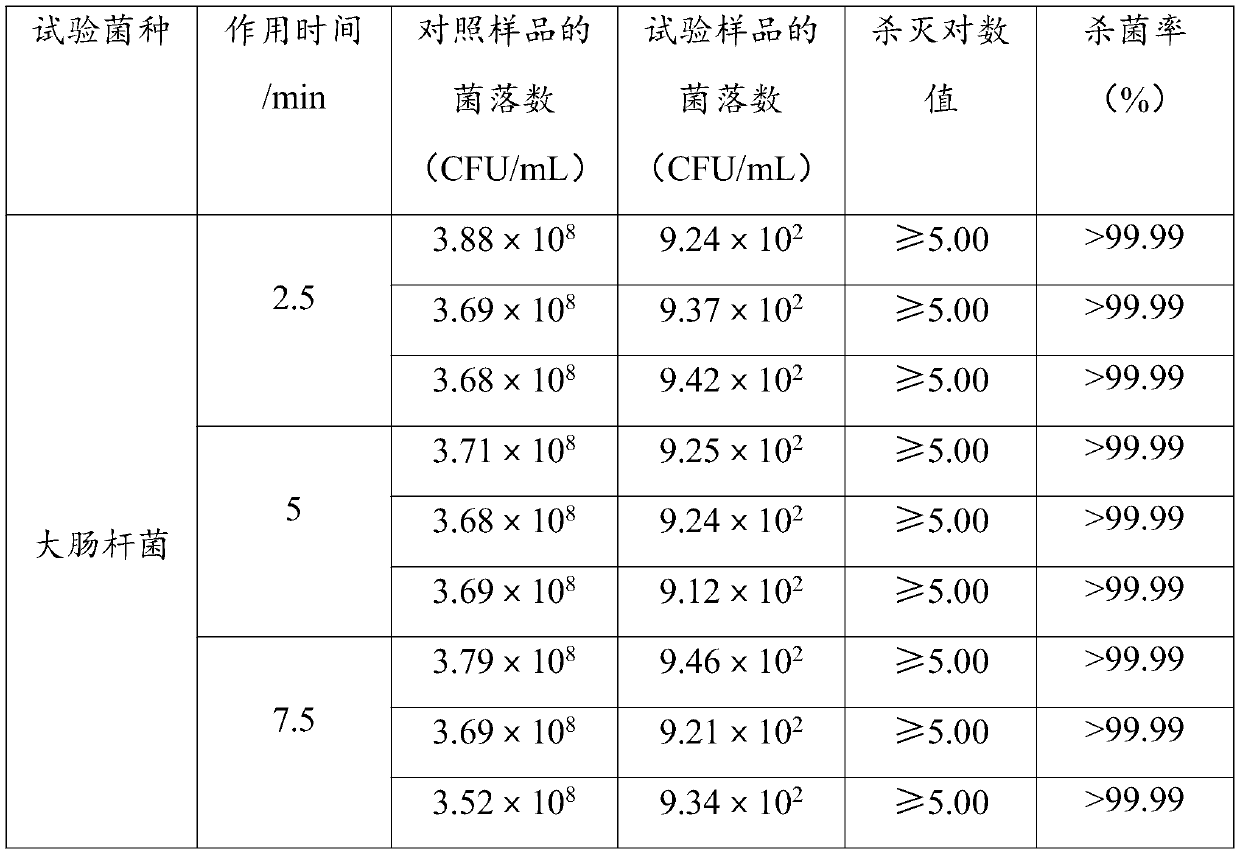

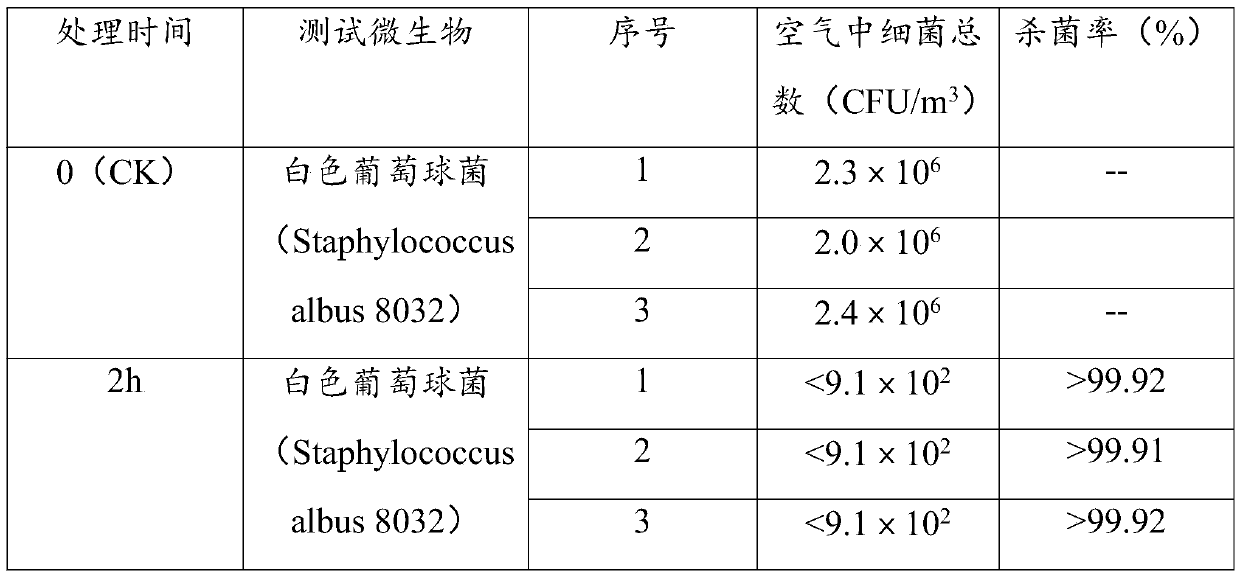

Method used

Image

Examples

Embodiment 1

[0029] A slow-release chlorine dioxide air purification gel, consisting of the following components in weight percentage: 1.8% of chlorine dioxide disinfectant, 10.3% of slow-release agent, 6.4% of gel, and 81.5% of deionized water; The chlorine oxide disinfectant is composed of the following components by weight: sodium chlorite, citric acid, sodium chloride, sodium bicarbonate, and magnesium sulfate in a ratio of 4:8:1:0.5:2; the slow-release agent is composed of the following weights: The composition of the proportioned components: the ratio of sodium dihydrogen phosphate, polyethylene glycol and citric acid is 0.5:0.6:0.5, and the gelling agent is sodium carboxymethyl cellulose.

[0030] A preparation method of the above-mentioned slow-release chlorine dioxide air purification gel, comprising the following steps:

[0031] 1) Weigh the components except deionized water according to the above weight percentage, and pour them into a powder mixer to fully mix the powder;

[0...

Embodiment 2

[0036] A slow-release chlorine dioxide air purification gel, consisting of the following components in percentage by weight: 3% chlorine dioxide disinfectant, 14.3% slow-release agent, 9.6% gel, 72.7% deionized water; The chlorine oxide disinfectant is composed of the following components by weight: sodium chlorite, citric acid, sodium chloride, sodium bicarbonate, and magnesium sulfate in a ratio of 6:10:3:2:4; the slow-release agent is composed of the following weights: The composition of the proportioned components: the ratio of sodium dihydrogen phosphate, polyethylene glycol and citric acid is 1.5:1.4:1.3, and the gelling agent is sodium carboxymethyl cellulose.

[0037] A preparation method of the above-mentioned slow-release chlorine dioxide air purification gel, comprising the following steps:

[0038] 1) Weigh the components except deionized water according to the above weight percentage, and pour them into a powder mixer to fully mix the powder;

[0039] 2) Weigh th...

Embodiment 3

[0043] A slow-release chlorine dioxide air purification gel, consisting of the following components in weight percentage: 1.9% chlorine dioxide disinfectant, 12.6% slow-release agent, 7.6% gel, 77.9% deionized water; The chlorine oxide disinfectant is composed of the following components by weight: sodium chlorite, citric acid, sodium chloride, sodium bicarbonate, and magnesium sulfate in a ratio of 4.5:8.5:1.5:1:2.5; the slow-release agent is composed of the following weights: Proportioned component composition: the ratio of sodium dihydrogen phosphate, polyethylene glycol and citric acid is 0.8:1:1.1, and the gelling agent is sodium carboxymethyl cellulose.

[0044] A preparation method of the above-mentioned slow-release chlorine dioxide air purification gel, comprising the following steps:

[0045] 1) Weigh the components except deionized water according to the above weight percentage, and pour them into a powder mixer to fully mix the powder;

[0046] 2) Weigh the powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com