Continuous production method for foam concrete

A foam concrete and production method technology, applied in the field of building materials, can solve the problems of low cost performance, high operation level requirements, long cycle, etc., and achieve the effect of enhancing workability and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

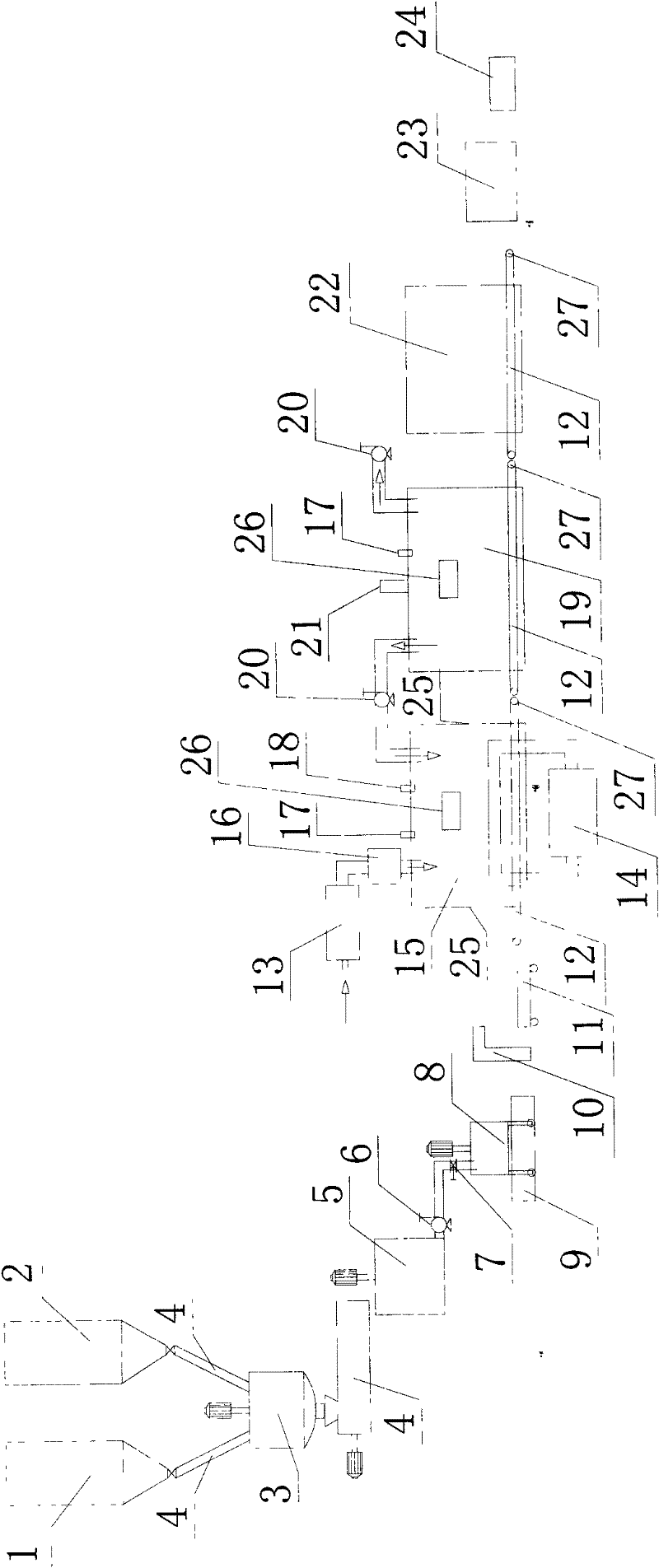

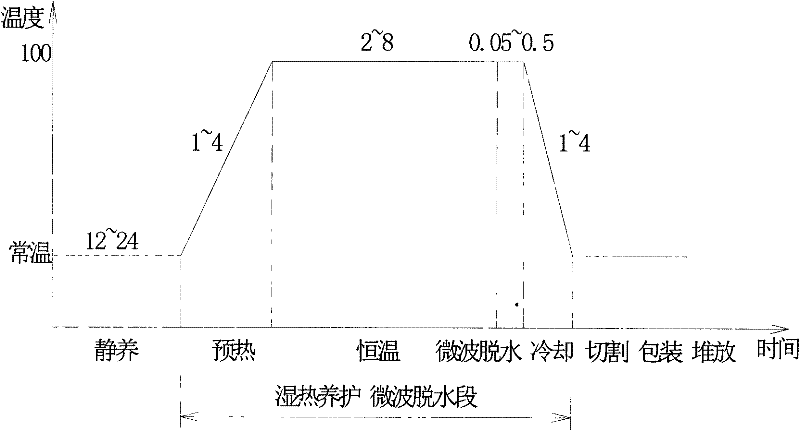

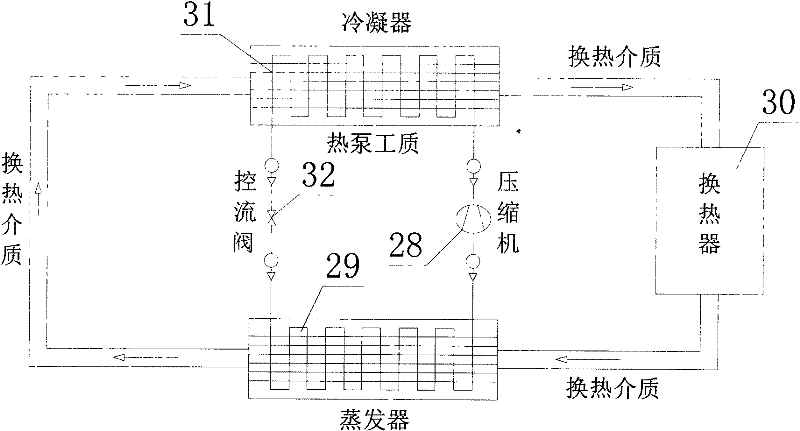

[0024] Embodiment one. Foam concrete continuous production method

[0025] The continuous production method of foam concrete in this example, its production process includes: preparing materials to the raw material warehouse, mixing and stirring raw materials, slurrying by pulping machine, adding foaming agent to foam, molding by injection molding machine, demoulding, natural curing, Cutting into materials, inspection, and qualified packaging, the continuous production method of foam concrete can be specified by Figure 1 ~ Figure 3 Jointly shown. figure 1 A schematic diagram of the process flow of the foamed concrete continuous production method is shown, as figure 1 As shown, 1 is storage bin 1, 2 is storage bin 2, 3 is a disperser, 4 is a screw propeller, 5 is a pulper, 6 is a mud pump, 7 is a valve, and 8 is a foaming injection molding machine , 9 is the mold, 10 is the manipulator, 11 is the drying car, 12 is the conveyor belt, 13 is the solar energy, 14 is the heat p...

Embodiment 2

[0026] Embodiment two. Foam concrete continuous production method

[0027] The continuous production method of foamed concrete in this example can generally be used Figure 1 ~ Figure 3 etc. have jointly shown that the continuous production method of foamed concrete in this example differs from the continuous production method of foamed concrete in Example 1 in that: 1. The preheating zone of the tunnel kiln structure is preheated for 1 hour. 2. The humid heat curing zone 15 of the tunnel kiln structure of this example. The wet heat curing process conditions: the temperature is 60° C., the relative humidity is 65%, and the time is 8 hours. 3. In the electromagnetic wave dehydration area 19 of the tunnel kiln structure, the rapid dehydration time is 0.05 hours by electromagnetic wave. 4. The tunnel kiln structure cooling zone 22 is cooled for 4 hours. 5. The formula ratio of foam concrete is: 200 parts of cement; 30 parts of fly ash; 100 parts of ore powder; 300 parts of wate...

Embodiment 3

[0028] Embodiment three. Foam concrete continuous production method

[0029] The continuous production method of foamed concrete in this example can generally be used Figure 1 ~ Figure 3 etc. jointly show that the foam concrete continuous production method of this example is different from the foam concrete continuous production method of embodiment one and embodiment two: 1. The preheating zone of the tunnel kiln structure is preheated for 3.5 hours. 2. The wet heat curing zone 15 of the tunnel kiln structure of this example The wet heat curing process conditions: the temperature is 85° C., the relative humidity is 85%, and the time is 3 hours. 3. In the electromagnetic wave dehydration zone 19 of the tunnel kiln structure, the rapid dehydration time is 0.4 hours by electromagnetic wave. 4. The tunnel kiln structure cooling zone 22 is cooled for 2 hours. 5. The formula ratio of foam concrete is: 200 parts of cement; 180 parts of fly ash; 30 parts of ore powder; 280 parts o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com