IoT (Internet of Things) service terminal for factory

A business terminal and Internet of Things technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of data distortion, reduction, and high data collection costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

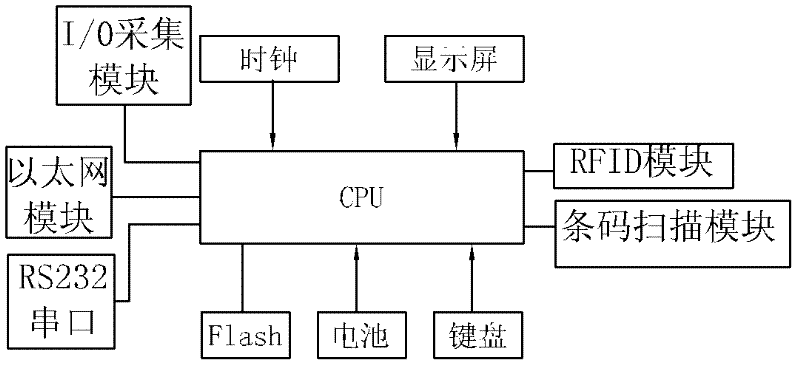

[0037] Embodiment: factory IoT business terminal, such as figure 1 As shown, it includes a data collector, and the data collector includes a CPU and a keyboard connected to the CPU, a battery, a flash, an RS232 serial port, an Ethernet module, an I / O acquisition module, a clock, a display screen, an RFID module, and a bar code scan module.

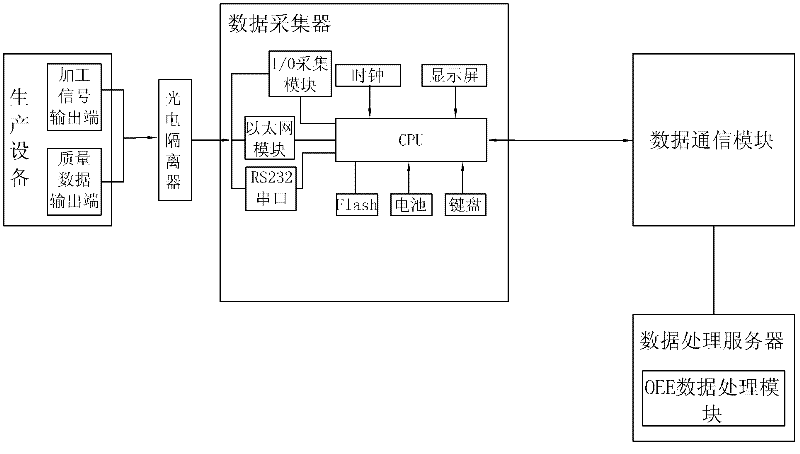

[0038] A kind of automatic measurement unit of global equipment efficiency OEE of the present invention, as figure 2 As shown, it includes: production equipment for processing workpieces, the production equipment has a processing signal output terminal and a quality signal output terminal; a photoelectric isolator is connected with the processing signal output terminal and quality signal output terminal of the production equipment, and is used to input , output signal isolation; data collector, the RS232 serial port of the data collector, Ethernet module, I / O acquisition module are connected to the photoelectric isolator to collect the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com