Dynamic secondary cooling control method for slab continuous casting based on double-cooling mode

A slab continuous casting and dynamic secondary cooling technology, applied in the field of metallurgical slab continuous casting, can solve the problems of continuous casting slab quality influence, uneven cooling, and casting slab quality influence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

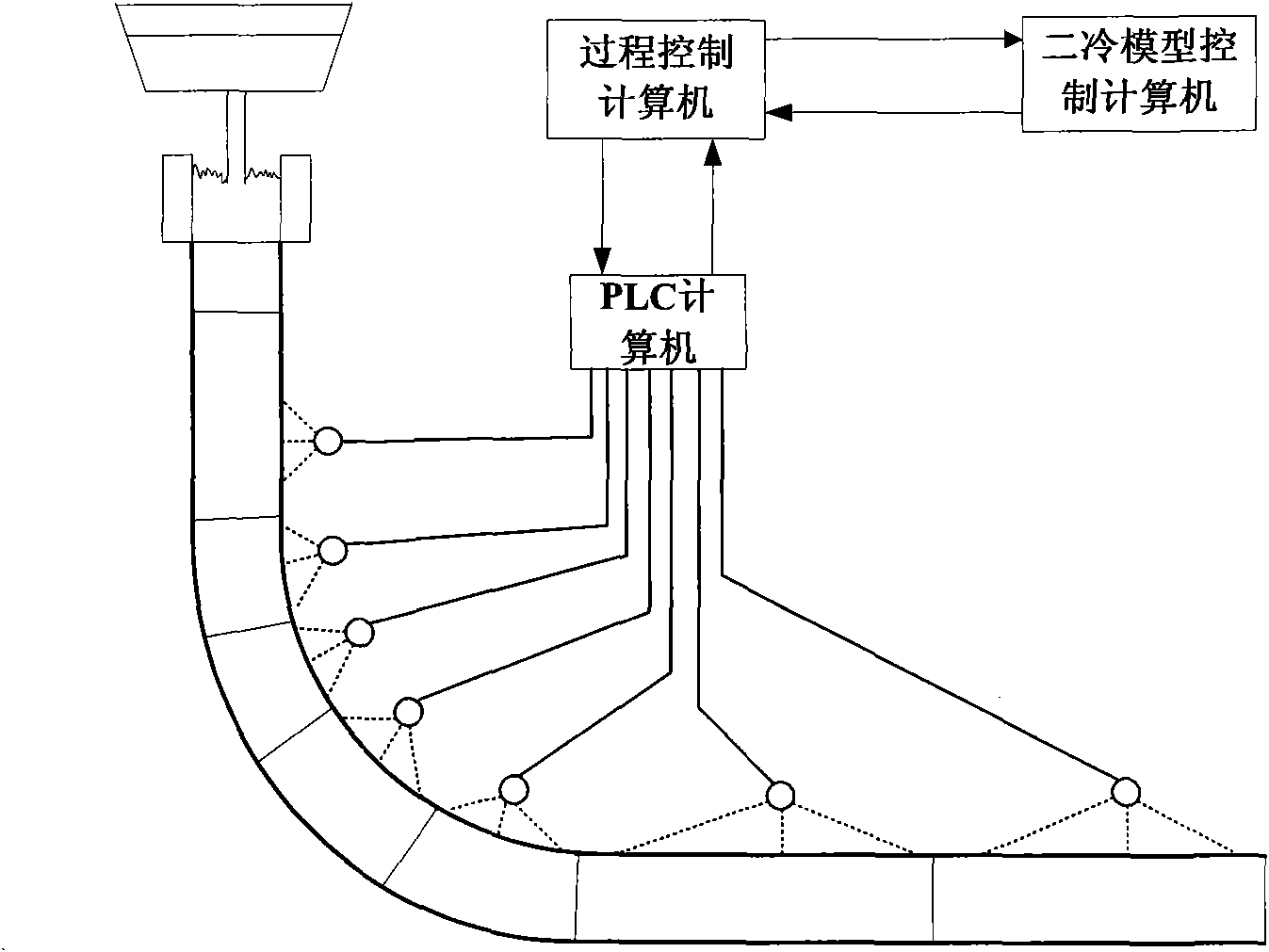

[0063] Such as image 3 Shown is a schematic diagram of the structure of the slab continuous casting secondary cooling control system.

[0064] In order to realize the periodic collection of process data, the model computer is required to be directly connected with the continuous casting process computer. During the control process, at regular time intervals, the model computer collects the latest casting data from the process computer, calculates the cooling water volume in all cooling zones, outputs control instructions and transmits them to the PLC computer for execution through the process computer.

[0065] The main parameters of the continuous casting machine in this embodiment are: the length of the casting machine is 32.31 m, and there are 13 segments and 9 cooling zones in total. The steel produced is mainly plain carbon steel, with three thicknesses (200mm, 220mm, and 250mm. The slab width ranges from 1500m to 2300mm, and the designed casting speed ranges from 0.4m / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com