YP500MPa-level thick steel plate with excellent low-temperature toughness and manufacturing method thereof

A technology with excellent low-temperature toughness, which is applied in the field of manufacturing TMCP type YP500MPa grade steel plates, and can solve problems affecting the low-temperature toughness level of thick steel plates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

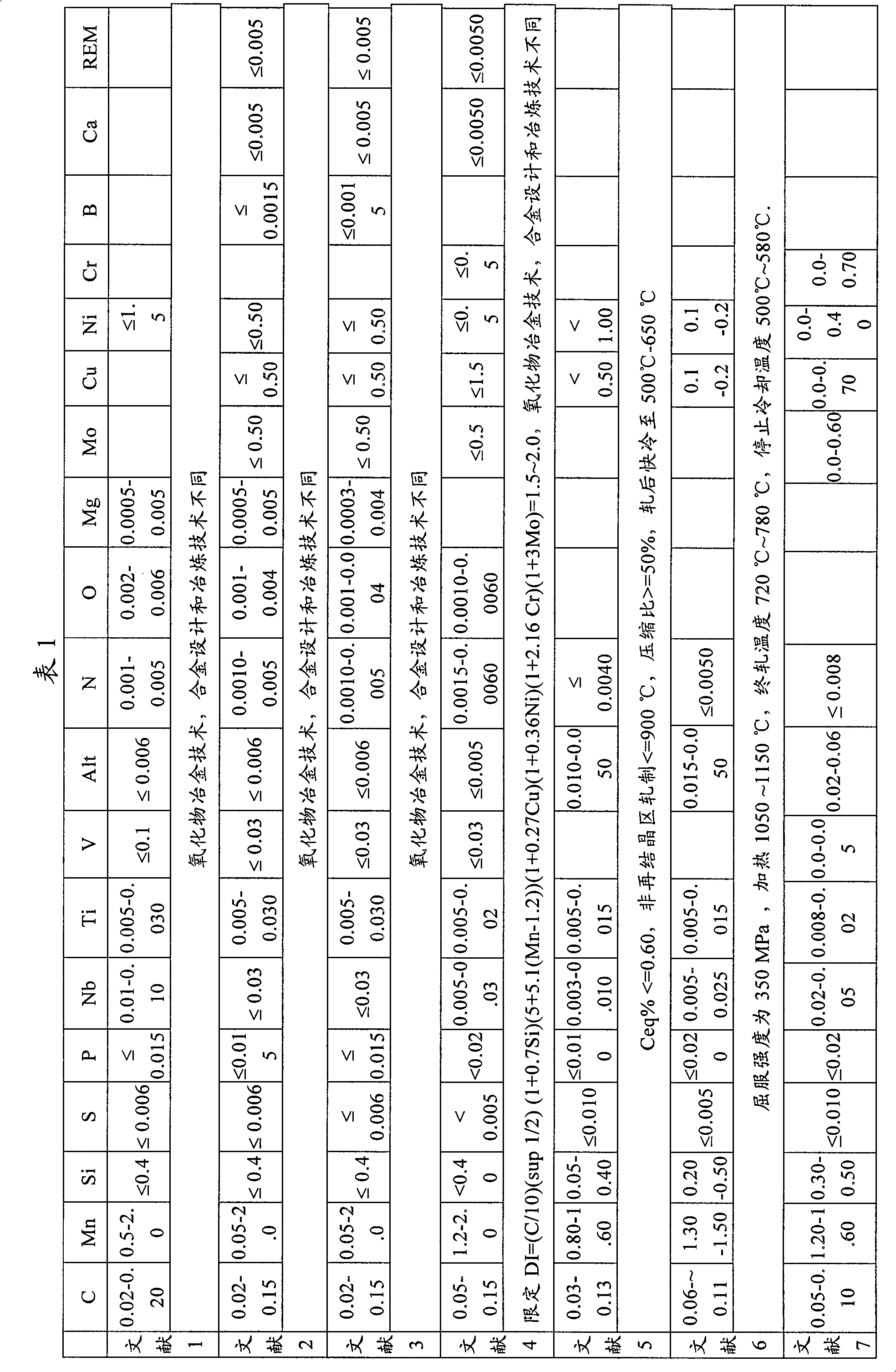

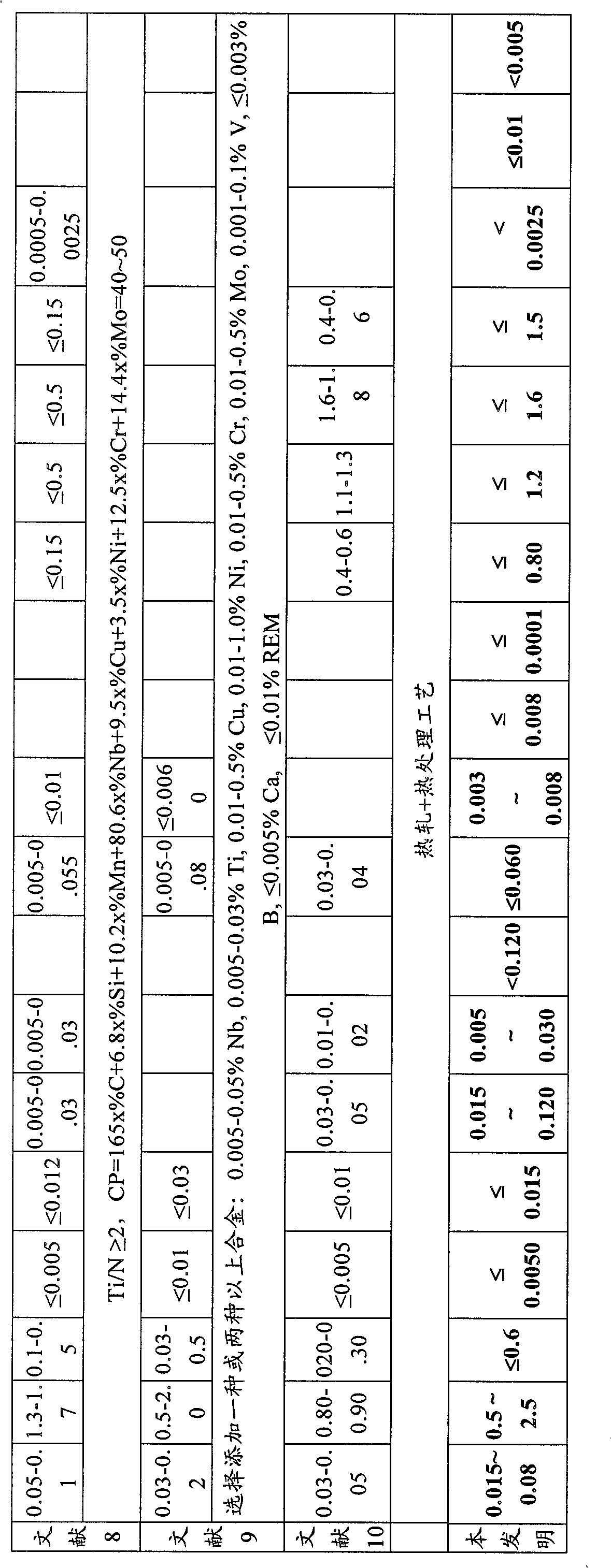

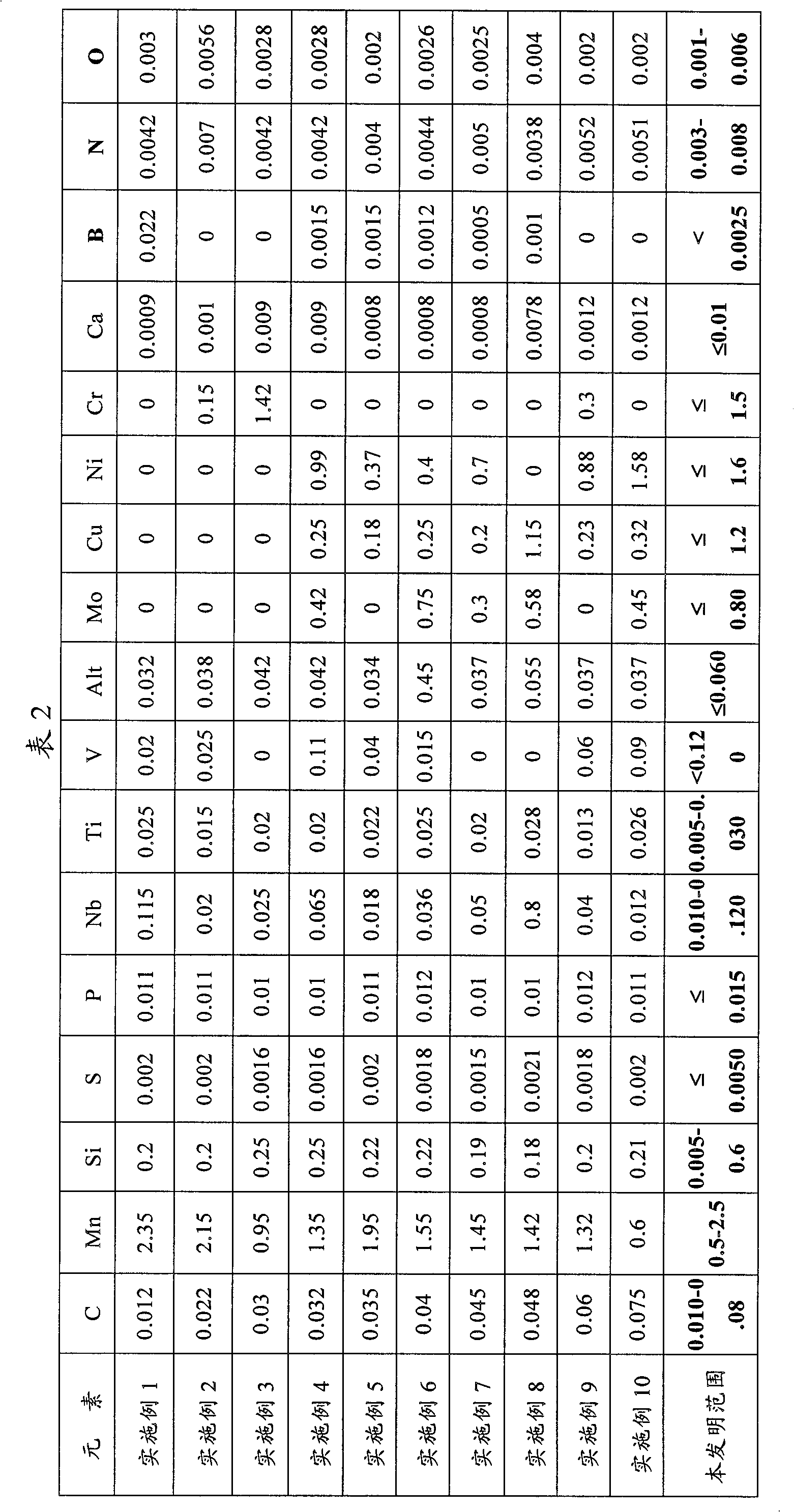

Method used

Image

Examples

Embodiment 1

[0052] It is used to manufacture high-strength ship plate steel with a thickness specification of 30mm. The heating temperature of the hot rolling process: 1200°C, the rolling temperature range of the recrystallization zone is 1130-980°C, the thickness of the intermediate waiting temperature is 100mm, and the temperature range of the non-recrystallization zone is 800-760°C. The termination cooling temperature is 380-400°C. The cooling rate is 12-15°C / s.

Embodiment 2

[0054] It is used to manufacture high-strength ship plate steel with a thickness specification of 40mm. The heating temperature of the hot rolling process: 1130°C, the rolling temperature range of the recrystallization zone is 1130-950°C, the thickness of the intermediate waiting temperature is 120mm, and the temperature range of the non-recrystallization zone is 800-750°C. The termination cooling temperature is 380-400°C. The cooling rate is 12-15°C / s.

Embodiment 3

[0056] It is used to manufacture high-strength ship plate steel with a thickness specification of 88mm. The heating temperature of the hot rolling process: 1130°C, the rolling temperature range of the recrystallization zone is 1100-950°C, the thickness of the intermediate waiting temperature is 200mm, and the temperature range of the non-recrystallization zone is 760-720°C. Stop cooling temperature 330-360 ℃. The cooling rate is 5-8°C / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com