Driving system of scraper conveyor and control method

一种刮板输送机、驱动系统的技术,应用在输送机控制装置、输送机、输送机物件等方向,能够解决双驱动系统功率不平衡等问题,达到运行速度稳定的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be described in detail below in conjunction with the drawings and specific embodiments.

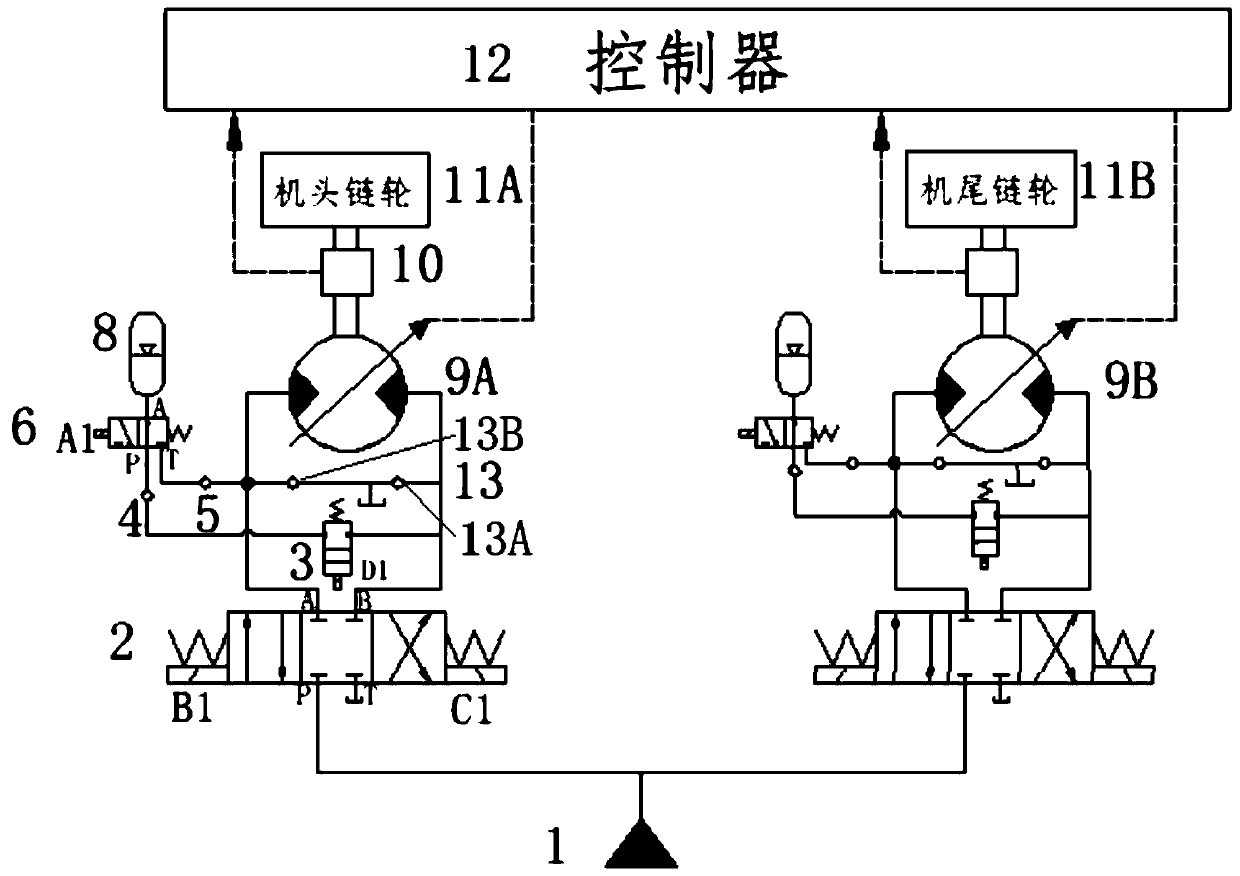

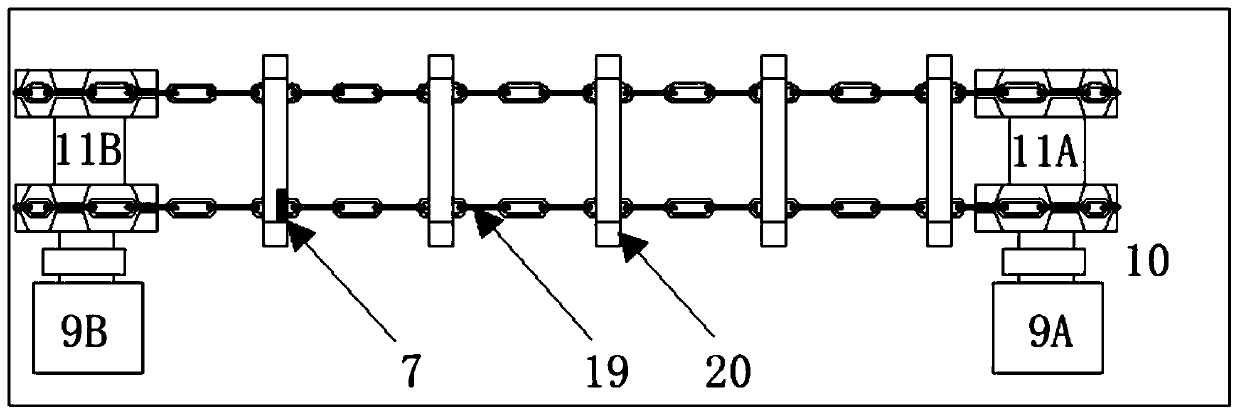

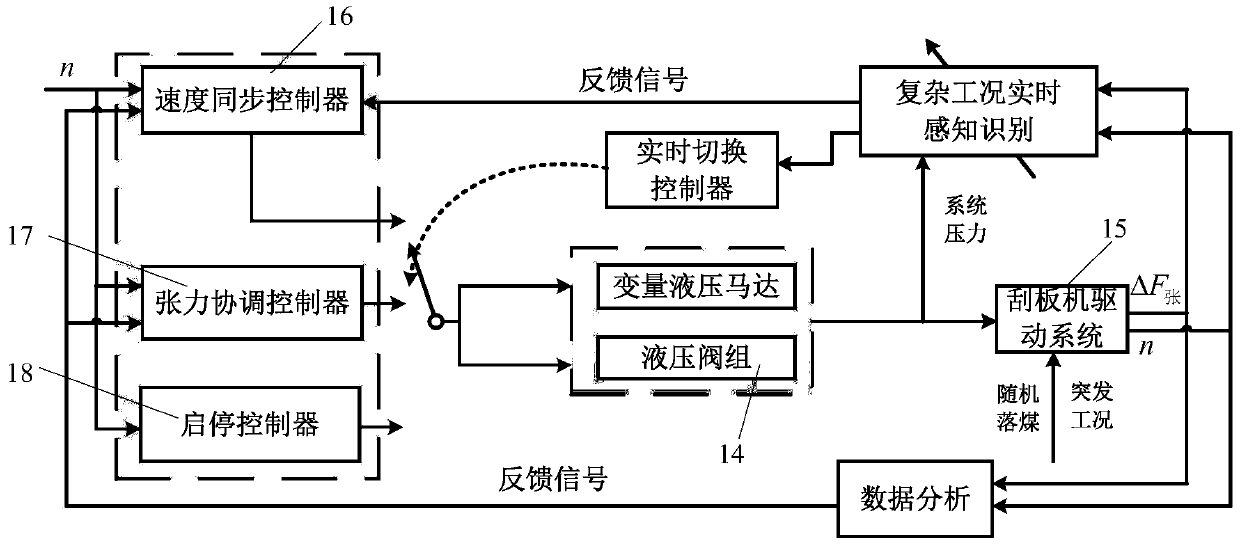

[0027] Such as figure 1 with figure 2 As shown, a drive system and control method of a scraper conveyor includes a head sprocket 11A, a tail sprocket 11B, a head sprocket drive mechanism, and a tail sprocket drive mechanism, wherein the head chain The wheel drive mechanism is hydraulic motor one 9A, and the tail sprocket drive mechanism is hydraulic motor two 9B; the hydraulic system driving hydraulic motor one and the hydraulic system driving hydraulic motor two include the same hydraulic components.

[0028] Now take the hydraulic system that drives the hydraulic motor 1 as an example, including three-position four-way electromagnetic directional valve 2, two-position two-way electromagnetic directional valve 3, two-position three-way electromagnetic directional valve 6, accumulator 8 and oil supplement Valve group 13, the oil inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com