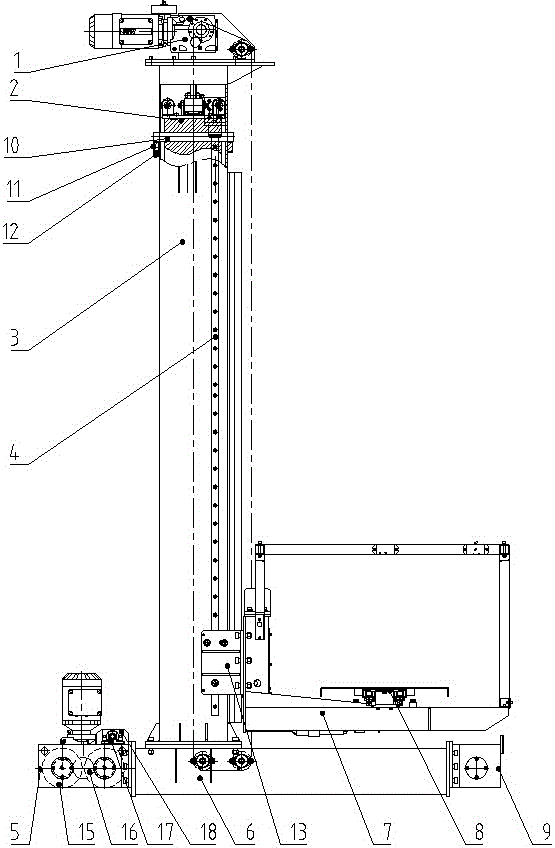

Double-drive counterweight high-speed stacking machine

A stacker and counterweight technology, applied in the field of warehousing and logistics equipment, can solve the problem of affecting the fork device to grab, transport and stacking access to goods, increase the loss of the power wheel and the friction motor of the track, and the running accuracy of the cargo platform. Stability reduction and other problems, to achieve the effect of high repeated positioning accuracy, improved service life, improved operation accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

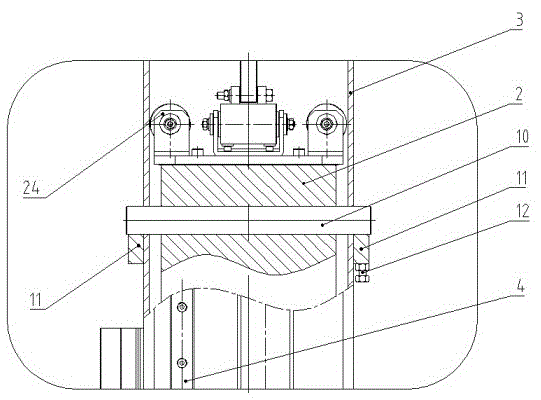

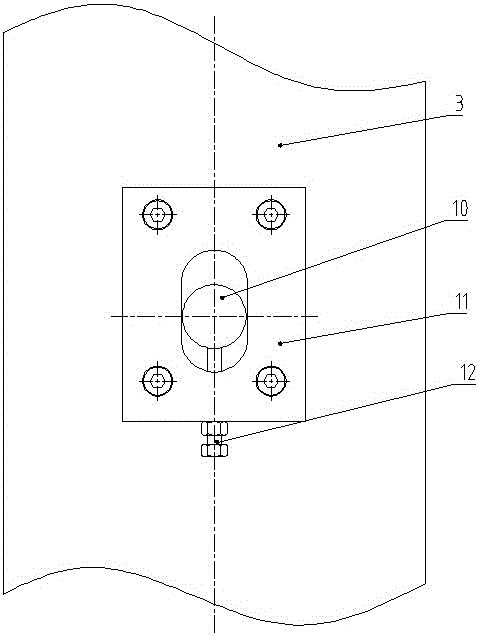

[0013] The lower beam 6 is as the base of the stacker, and the active wheel box earrings 17 and the lower beam earrings 18 in the lower beam 6 are hinged together with pins in the active walking system 5 . Passive walking system 9 is installed on the passive wheel box mounting plate of lower beam 6. The lower flange of the column in the column 3 is connected with the column mounting plate of the lower beam 6, the linear guide rail 4 is installed on both sides of the column 3, the slider 13 in the linear guide rail 4 is connected with the slider mounting plate in the loading platform 7, and the fork 8 Installed on the loading platform 7, the counterweight 2 is installed in the column 3, and the lifting system 1 is connected to the upper flange of the column 3; Installed on the column 3, the adjusting bolt 12 is installed on the fixed block 11, and the pin shaft 10 passes through the fixed block 11 and the counterweight 2 to connect the two together. Driving wheel box 14, walki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com