Automatic feeding speed control method based on template sewing machine controller

A speed control, automatic feeding technology, applied in the direction of digital control, program control, electrical program control, etc., can solve the problems of poor stability, jitter, low precision, etc., achieve high real-time performance, reasonable running speed, and reduce calculation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Further description will be made below in conjunction with accompanying drawings.

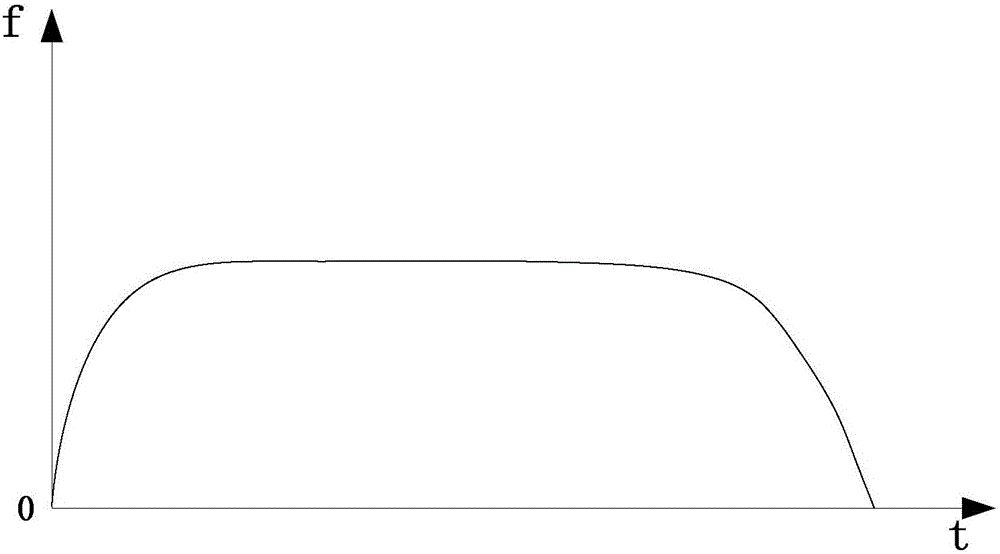

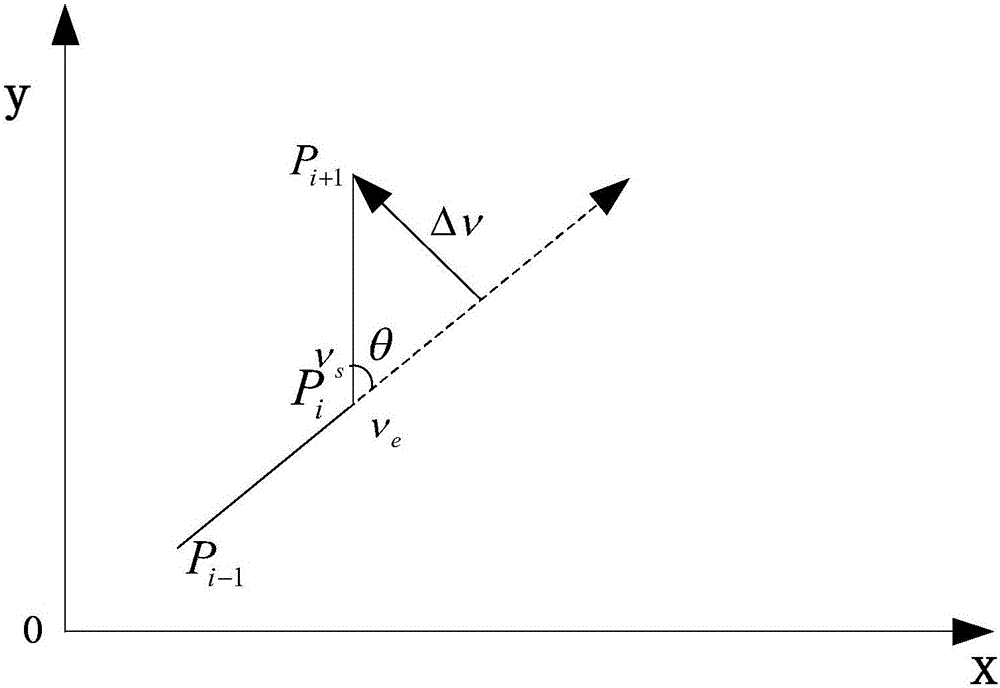

[0021] refer to figure 1 and figure 2 , an automatic feeding speed control method based on a template sewing machine controller, comprising the following steps:

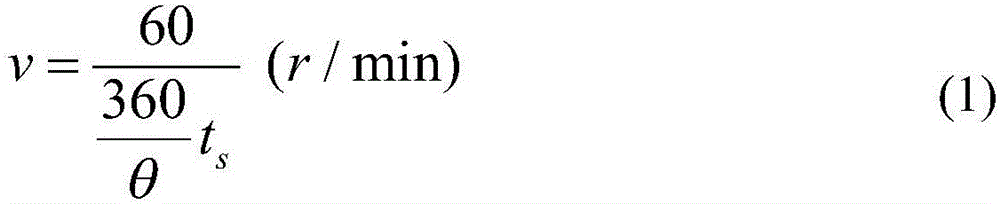

[0022] 1) The formula for calculating the speed of the servo motor is as follows:

[0023] v = 60 360 θ t s ( r / m i n ) - - - ( 1 )

[0024] v = 1 6 θf s ( r / m i n ) - - ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com