Method for reconstructing cylindrical gas holder

A cylindrical, gas cabinet technology, applied in adjustable capacity gas storage tanks, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of long construction time, huge investment in construction funds, etc. The effect of low operating cost and short construction organization period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

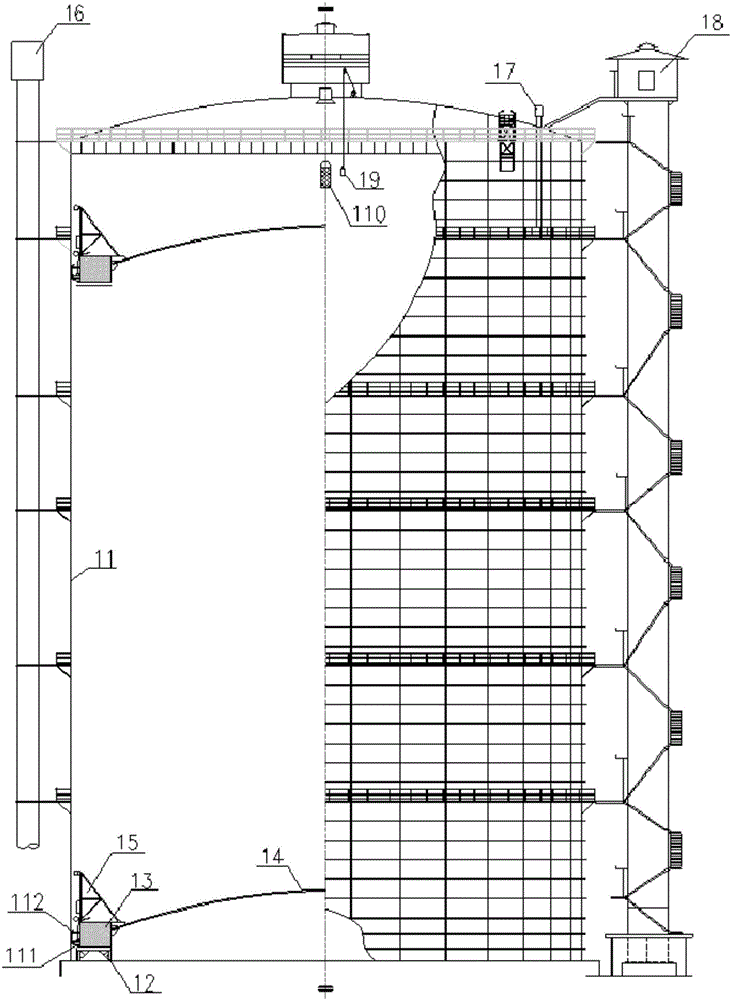

[0029] like figure 1 As shown, the cylindrical gas cabinet includes a cabinet body 11, a piston bracket 12, a piston box beam 13, a piston center spherical shell 14, a gas release pipe 16, an emergency release pipe 17, an elevator and a ladder 18, a temporary rescue device 19, and an internal crane. Cage 110, sealing device hanging ring beam 111, piston guide wheel bracket 15 and sealing mechanism 112,

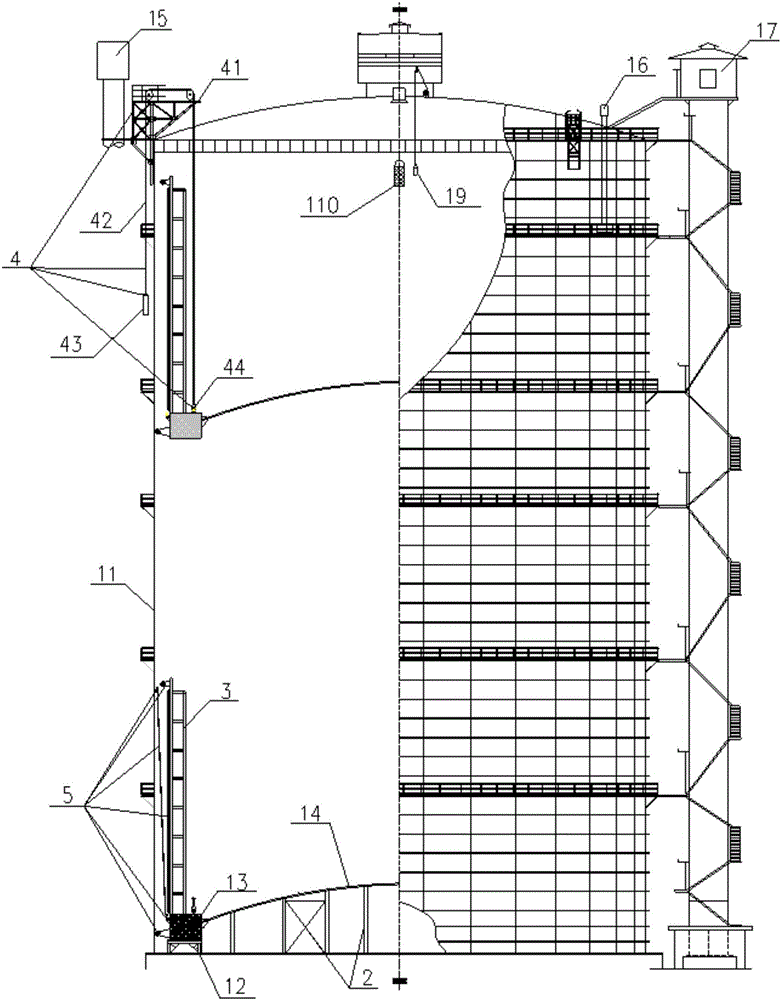

[0030] The transformation method of the cylindrical gas cabinet of the present embodiment is cabinet body 11, piston bracket 12, piston box beam 13, piston spherical shell 14, gas release pipe 16, emergency release pipe 17, elevator and ladder 18, temporary rescue device 19 , Internal hanging cage 110, sealing device Hanging ring beam 111 remains still, remove the piston guide wheel bracket 15 and sealing mechanism 112 of the cylindrical gas tank, add piston center support 2, rubber seal piston fence 3, leveling system 4 and sealing system5. The specific steps are as follows...

Embodiment 2

[0040] On the basis of the above-mentioned embodiments, a support step is also included between step 2 and step 3: a number of center supports 2 are arranged below the center spherical shell of the cylindrical gas tank piston, so that the top ends of each center support 2 The determined arc surface is the same shape as the lower surface of the central spherical shell.

[0041] In this embodiment, a support is provided under the center spherical shell, and the shape of the lower surface of the central spherical shell is the same, so that when the piston falls, the central spherical shell can withstand a certain pressure without deformation. Therefore, the materials and tools needed in the construction process can be placed on the central spherical shell, which provides convenience for the construction process.

Embodiment 3

[0043] On the basis of the above-mentioned embodiment, after step 5, it also includes 4 steps of installing the leveling device: setting a leveling suspension point 44 on the piston ring beam, setting a leveling support 41 on the top of the cylindrical gas tank cabinet body 11, A pulley is set on the leveling bracket 41, the leveling wire rope 42 is matched with the leveling bracket, one end of the leveling wire rope 42 is connected to the leveling lifting point 44, and the other end of the leveling wire rope 42 is connected to level Hammer 43.

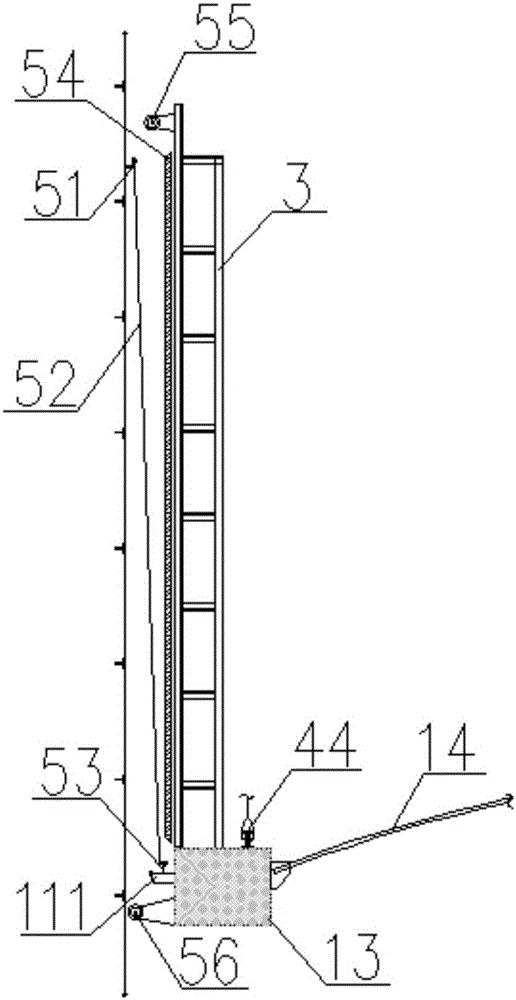

[0044] In this embodiment, a leveling device 4 is provided for the piston. The leveling device 4 can adjust the angle and shape of the piston, thereby avoiding the piston from colliding with the side plate of the cabinet 11 due to drifting, and avoiding the collision between the piston and the side of the cabinet 11. The plates collide and damage the rubber membrane 52 . Therefore, the service life of the rubber membrane 52 can be exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com