System and method for controlling motion of yarn guide of full-automatic computerized flat knitting machine

A motion control system and computerized flat knitting technology, applied in the control of using feedback, textile and paper making, weft knitting, etc., can solve the problems of unstable performance of yarn feeder electromagnets, inaccurate positioning of yarn feeders, and damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

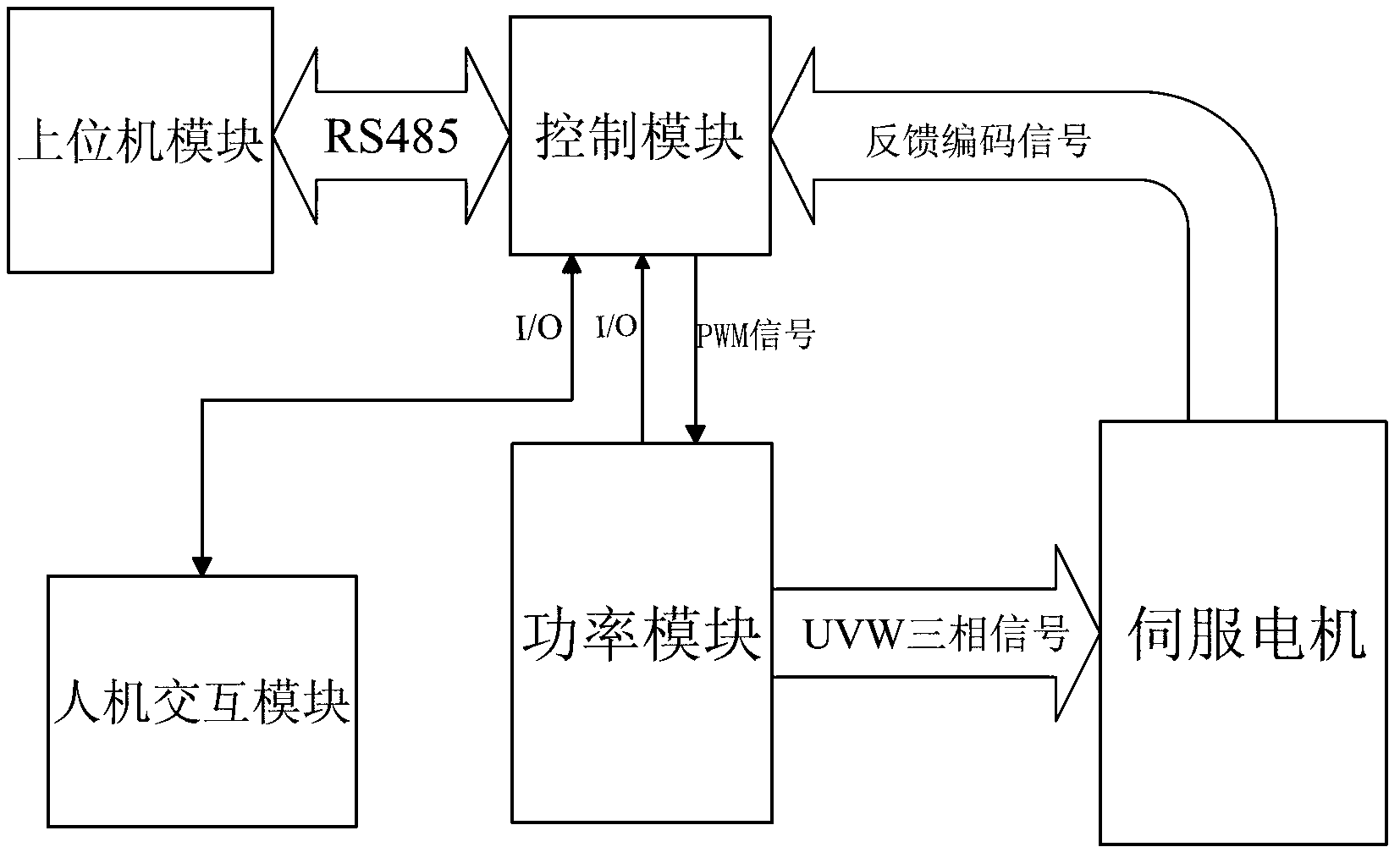

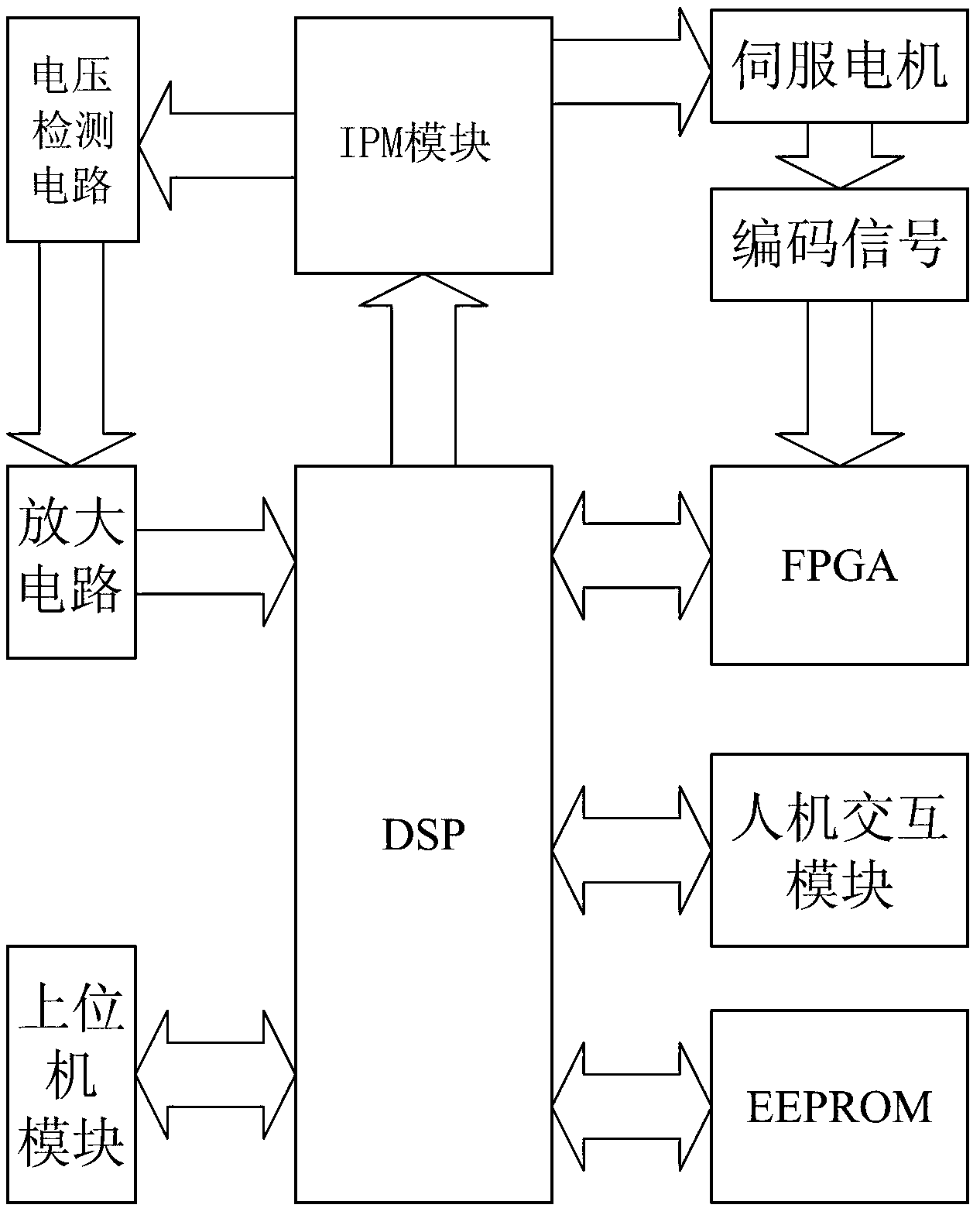

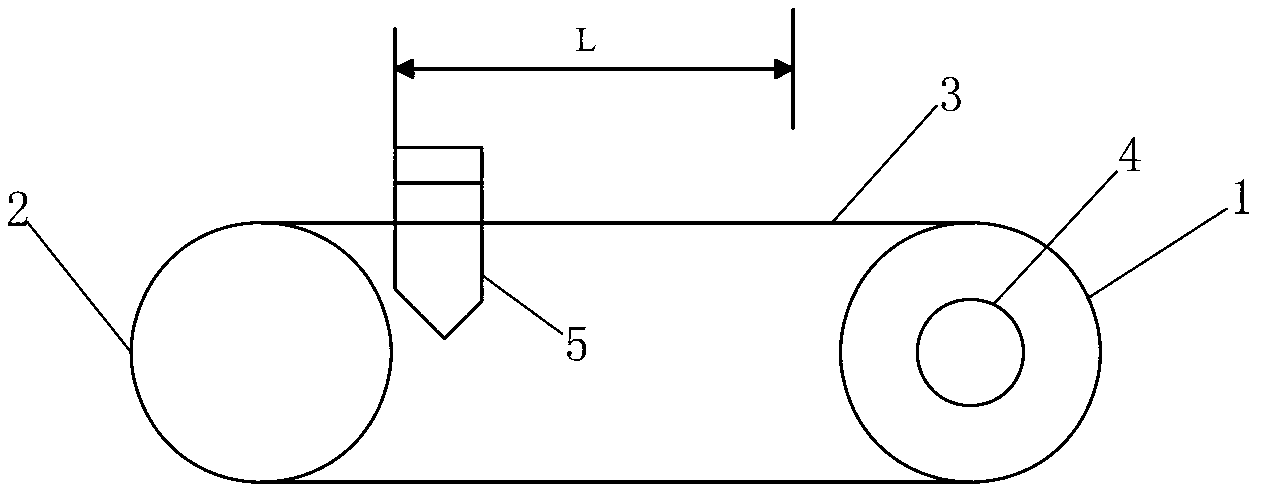

[0031] Embodiment: a kind of yarn guide motion control system of fully automatic computerized flat knitting machine, as figure 1 , figure 2 as shown,

[0032] include:

[0033] The upper computer module communicates with the control module through the RS485 protocol, generates the control command of the servo motor and sends it to the control module, and receives the return result after the command is executed from the control module. The control command here mainly includes the running distance and direction of the yarn guide; the returned result here refers to the running distance and running direction of the current yarn guide.

[0034] The human-computer interaction module includes buttons and digital tubes. The parameters of the servo motor operation are set through the buttons, and the running status of the servo motor is displayed using the digital tubes.

[0035] The control module is used to: receive the control command output by the upper computer module, receive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com