Protecting device of welding seam of titanium-steel composite plate of sleeve-type chimney and use method of protecting device

A protective device and composite plate technology, which is applied in the direction of welding protection devices, auxiliary devices, welding equipment, etc., can solve the problems of reducing the corrosion resistance of titanium materials, low potential of titanium iron electrodes, and difficult to guarantee, so as to speed up construction efficiency , Convenient construction organization, convenient construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

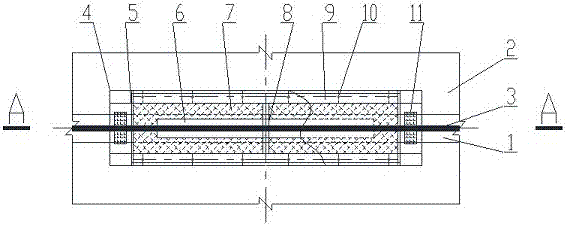

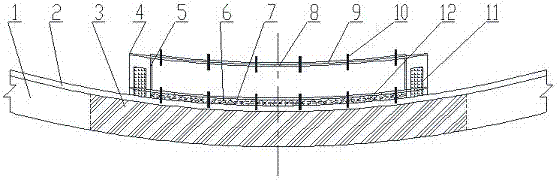

[0016] In the figure, a sleeve type chimney titanium steel composite plate welding seam protection device of the present invention is mainly composed of steel plate 1, titanium plate 2, weld seam 3, C-shaped steel 4, end steel plate 5, elongated notch 6, Rock wool 7, connecting steel plate 8, cover plate 9, bolt 10, magnet 11, iron bar 12 are formed.

[0017] The present invention is a sleeve-type chimney titanium-steel composite plate welding seam protection device, which consists of figure 1 and figure 2 It can be seen that after the titanium-steel composite plate is rolled and assembled in the smoke exhaust inner tube of the sleeve-type chimney, before the butt joint V-shaped weld 3 of the titanium-steel composite plate is welded, the protection device is made of galvanized C-shaped steel 4 on the 2 sides of the welded titanium plate , The C-shaped steel 4 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com