Complete-set steel casing construction method of concrete cast-in-place bored pile passing through underground gallery

A technology of bored piles and construction methods, which is applied to drill bits, sheet pile walls, drilling equipment, etc., can solve the problems of the installation of separate partition steel casings, the difficulty of drilling and forming of top and bottom plates, and the large gaps, etc. To achieve the effect of convenient construction organization, improved working environment and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

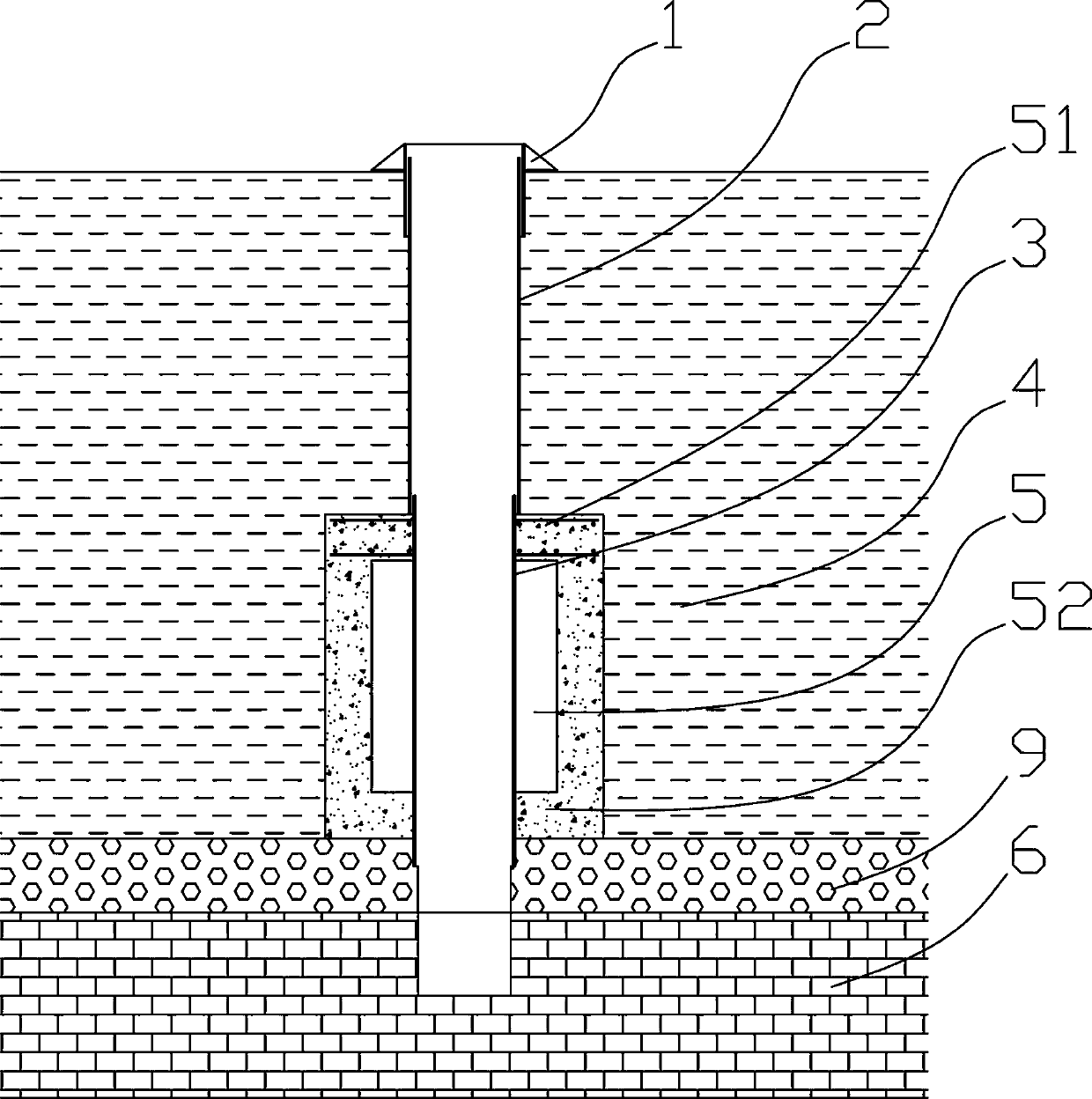

[0039] Such as Figure 1~3 Among them, a construction method for a complete set of steel casings for concrete bored piles passing through underground corridors, comprising the following steps:

[0040] S1. For construction lofting and pile foundation positioning, use a rotary drilling rig to install a rotary drilling bucket for drilling;

[0041] S2, embedding positioning steel casing 1;

[0042] The preferred solution is as figure 1 Among them, the top elevation of the positioning steel casing 1 should exceed the elevation of the pile foundation concrete pouring storage surface elevation, and the pile foundation concrete pouring storage surface elevation includes the pile head breaking length;

[0043] S3. Use the rotary drilling bucket or the auger bit to drill holes in the soil body 4, and simultaneously follow up the retaining wall steel casing 2 while drilling;

[0044] The length of the retaining wall steel casing 2 is consistent with the thickness of the soil body 4 ...

Embodiment 2

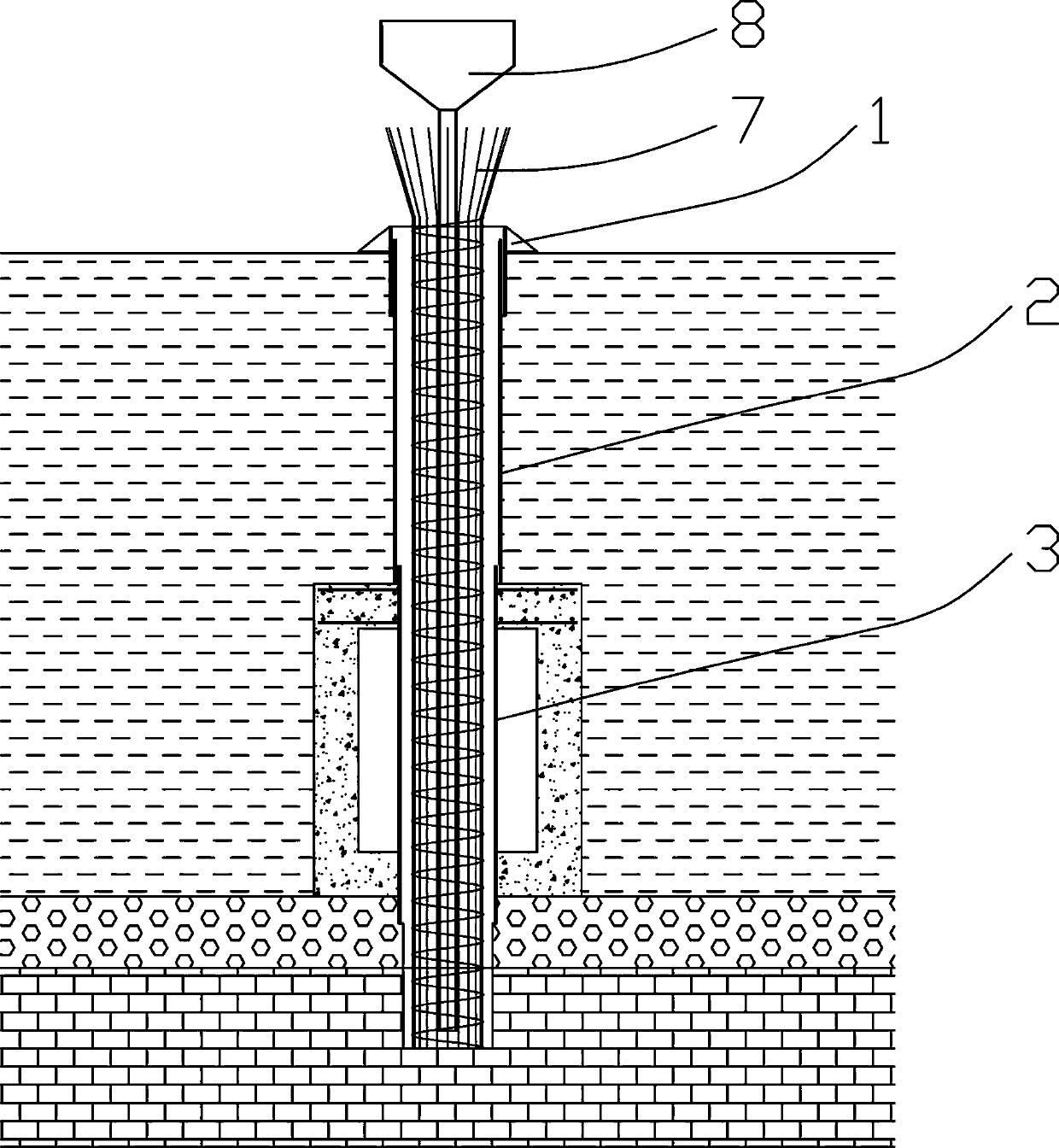

[0064] On the basis of Example 1, in the preferred solution, during the drilling process, the drilling speed of the rotary drilling bucket or the auger bit is recorded, and when the drilling speed slows down, it is prompted to drill to the position of the corridor roof 51 , lift the drilling tool up to replace the barrel core bit;

[0065] During the drilling process, the drilling speed is also recorded. When the drilling speed becomes faster, it will prompt to drill through the steel bar. At this time, the pressure will be reduced. Enter or separate the steel casing 3 and lower it for construction;

[0066] The judging mode of drilling into the corridor floor 52 is the same as the judging mode of drilling through the corridor roof 51.

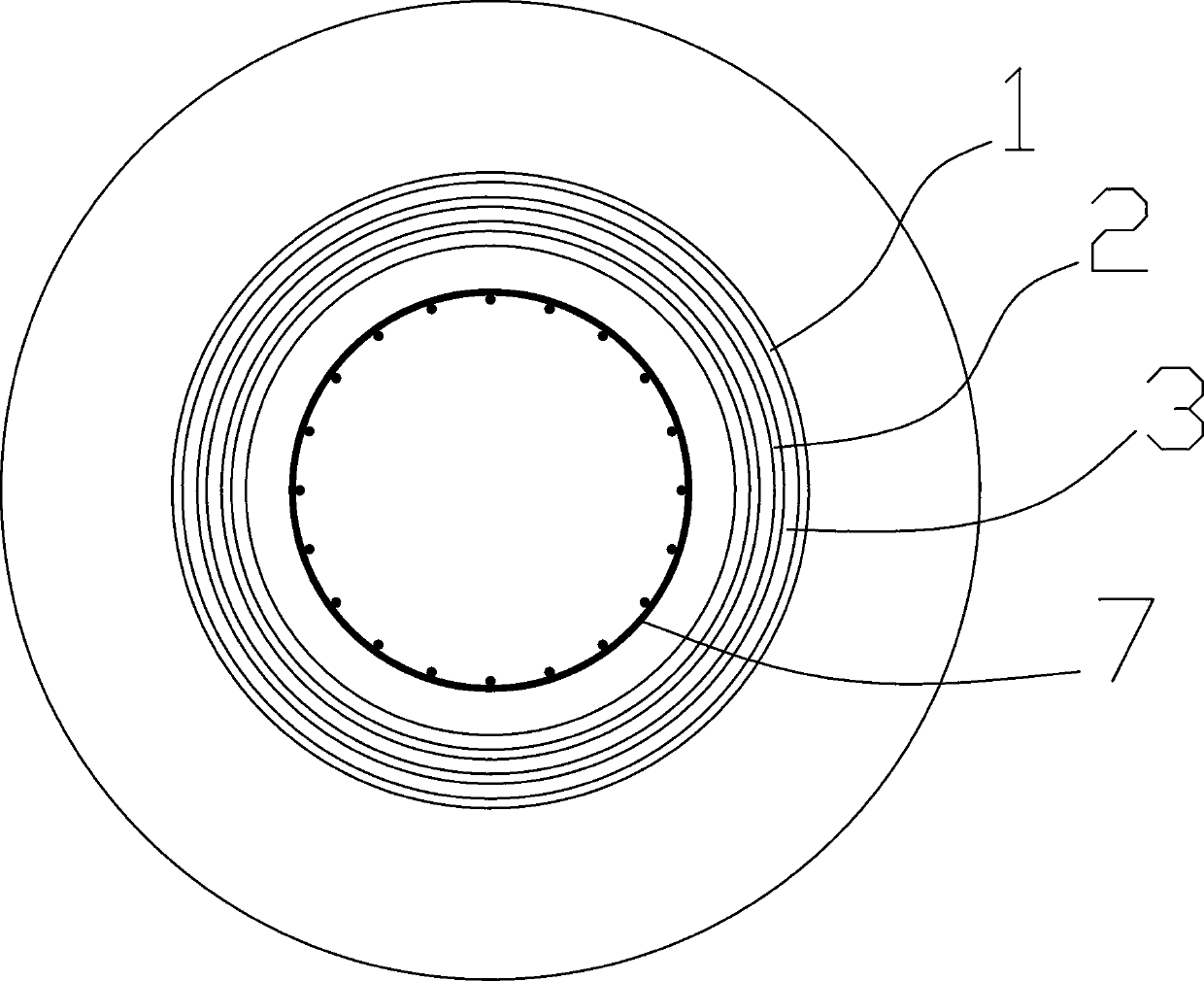

[0067] The preferred solution is as Figure 5 , 6 Among them, the top of the steel casing 3 is separated, and a plurality of slits along the circumference are set.

[0068] After lowering into place, replace the eccentric drilling hammer 1...

Embodiment 3

[0070] A construction project is located on the left side of the dam, which used to be a concrete construction stockyard. There is a prefabricated reinforced concrete drainage corridor with a height of 2 meters and a width of 1.5 meters in the stockyard area. When the channel was excavated, the material yard was abandoned and used as the excavation spoil yard. According to investigation, the thickness of the upper miscellaneous fill is about 3-4 meters, the content of sand and pebbles is relatively large, and the soil quality is relatively loose. The undisturbed soil at the bottom of the drainage corridor is about 1.5 meters thick, and then it is moderately weathered sandstone. The foundation of this project adopts the reinforced concrete bored pile structure, the pile diameter is 1 meter, and the pile foundation is embedded in the weathered rock of 1 meter. According to the site conditions, it was decided to use a rotary drilling rig for construction. Altogether 4 piles are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com