Treatment method of sinkhole in karst landform road roadbed range

A treatment method and sinkhole technology, applied to roads, roads, fillings, etc., can solve problems such as subgrade soil soaking, subgrade softening, and loss, and achieve the effects of less site occupation, improved anti-scourability, and enhanced frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

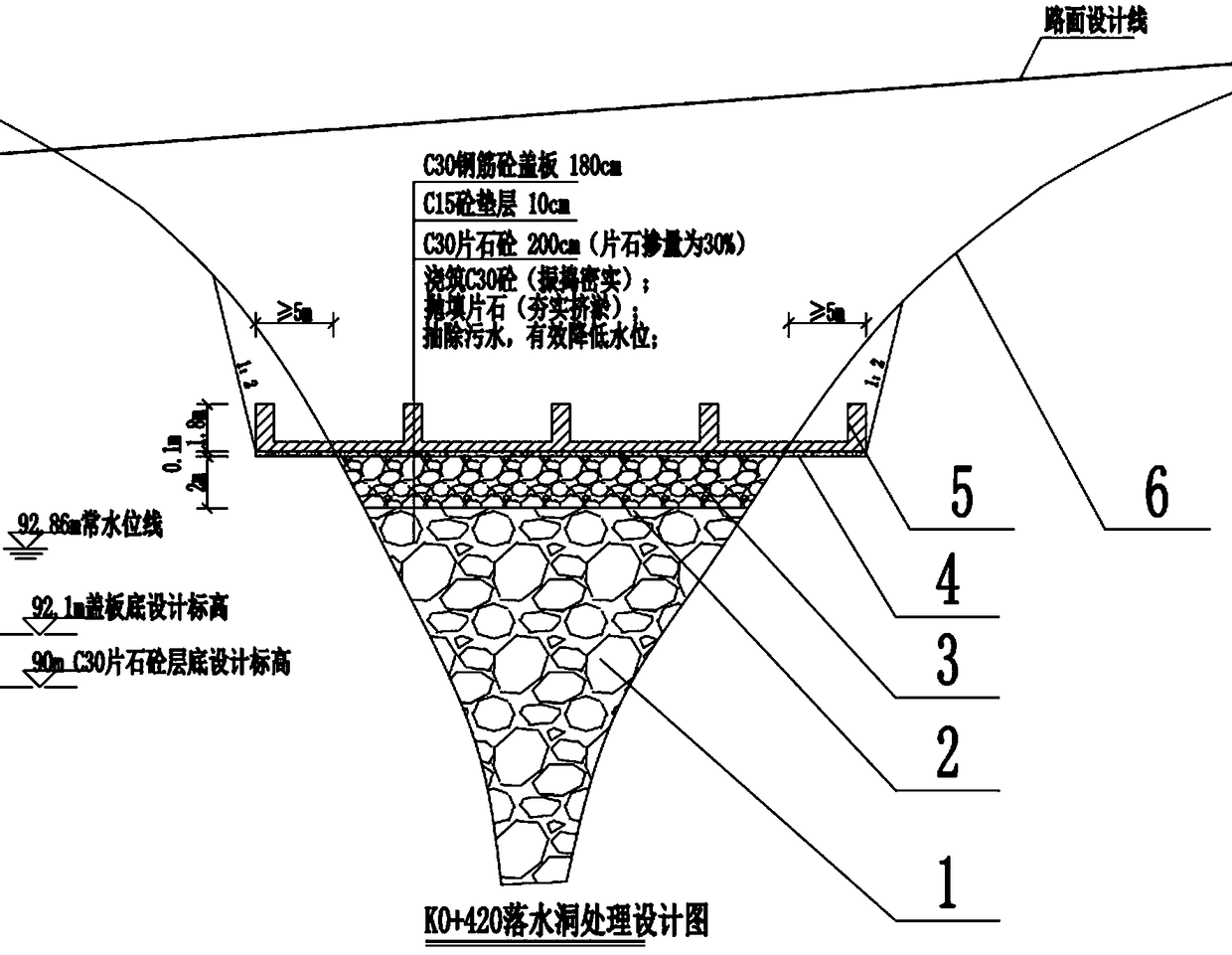

[0042] The following steps can be used to complete the treatment of sinkholes within the subgrade range of karst landform roads:

[0043] (1) Pumping water and sewage, effectively reducing the water level of the sinkhole;

[0044] (2) Use an excavator to throw the flake 1 evenly along the sinkhole, and squeeze it into the mud with a bucket tamp. The particle size of the flake 1 is not less than 70cm.

[0045] (3) After the rubble 1 is thrown to the design elevation, pour C30 concrete 2 to completely cover the rubble 1, and vibrate for compaction.

[0046] (4) Re-pour C30 rubble concrete 3 to the design elevation of the cover plate bottom; the rubble content of C30 rubble concrete is 30%, and the rubble particle size is 60-80cm.

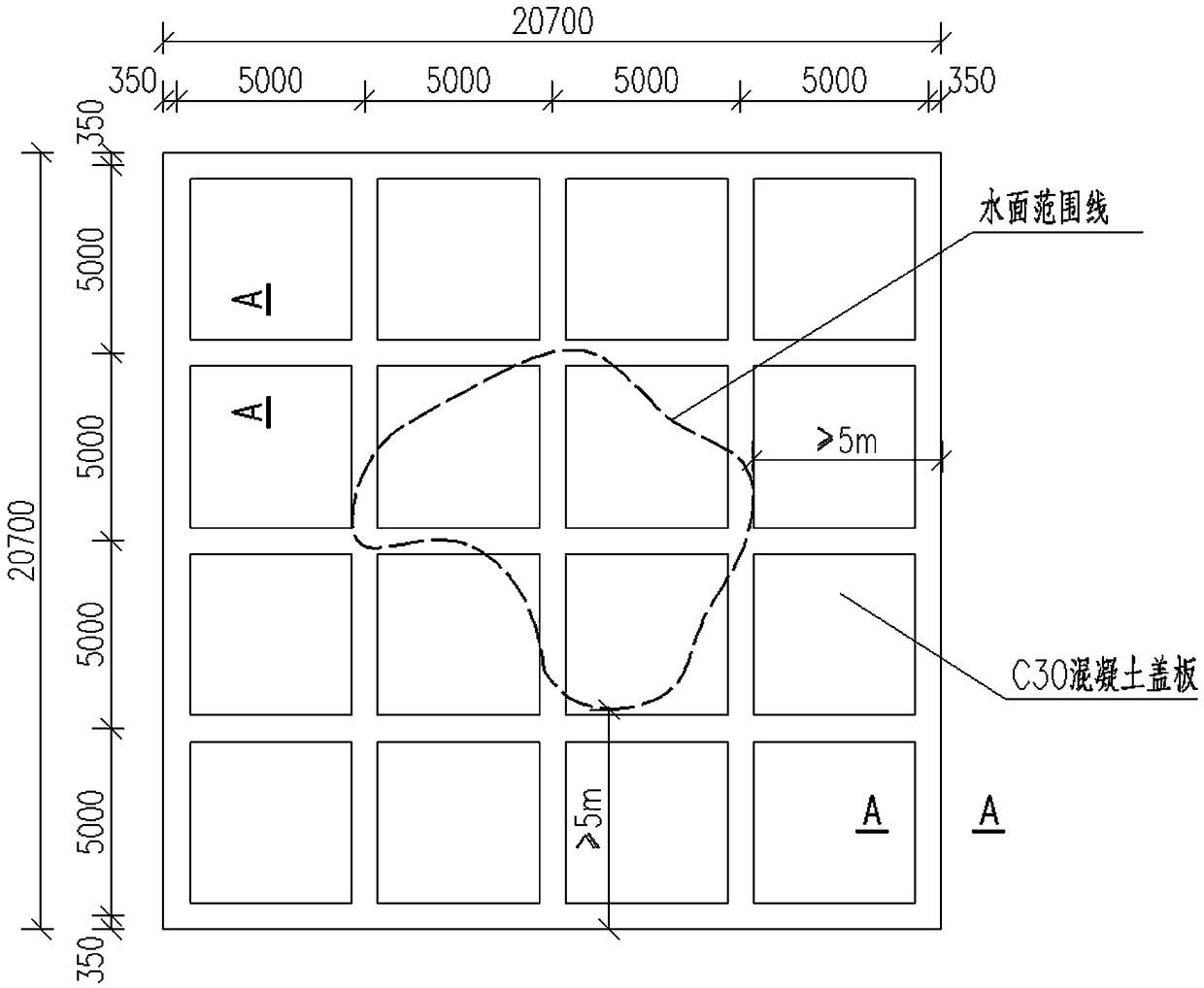

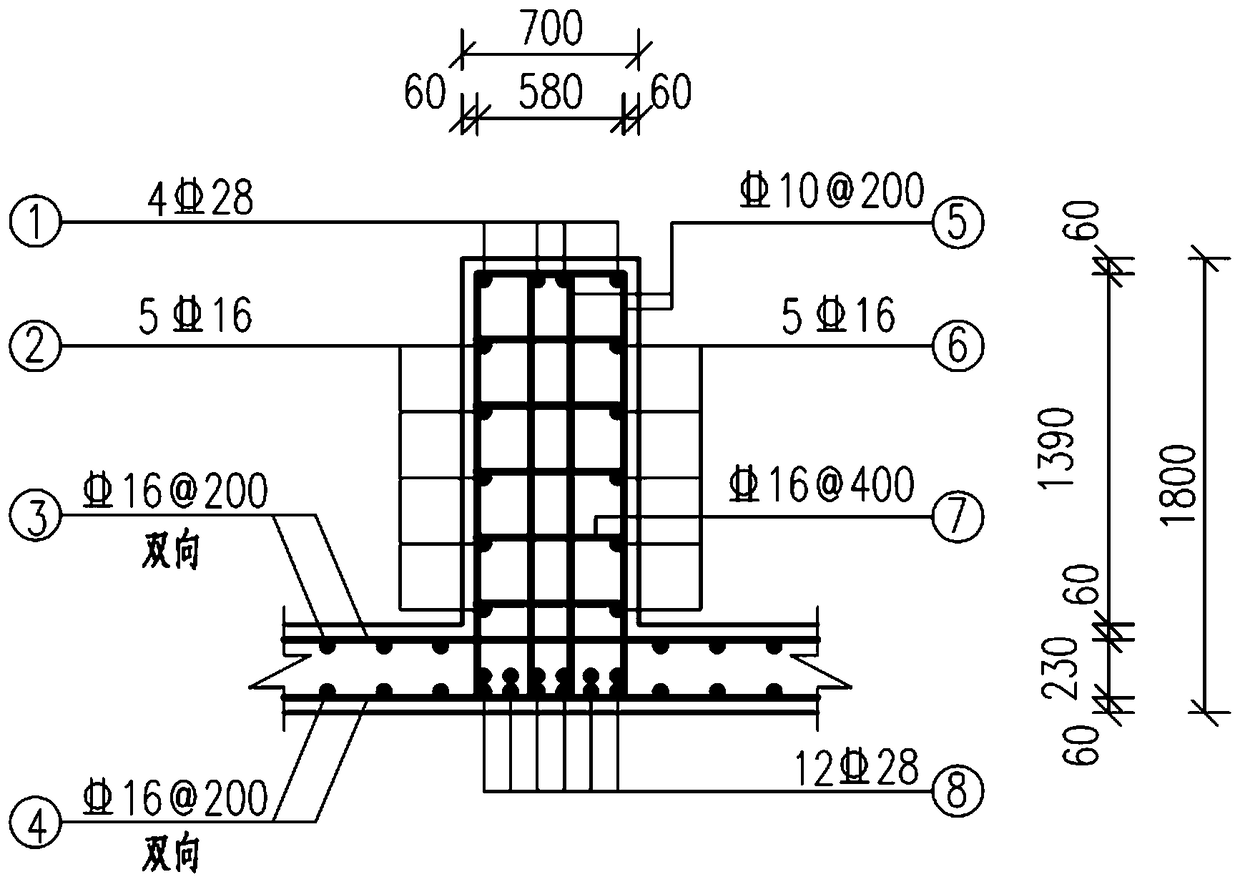

[0047] (5) After the C30 rubble concrete layer is consolidated, level the site, apply C30 reinforced concrete rib cover plate 5, and set a leveling layer 4 between the cover plate and the rubble concrete layer; the edge line of C30 reinforced concrete ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com