High-side-wall anchored primary support structure for rock strata underground excavation underground structure, and construction method of high-side-wall anchored primary support structure

An underground structure and stratum technology, used in underground chambers, earthwork drilling, wellbore lining, etc., can solve the problem of increasing the arch structure and stratum settlement deformation, unfavorable surrounding rock and rapid closure of the structure, unable to realize large-scale mechanized construction, etc. problems, to achieve the effect of reducing the amount of abandoned projects, convenient construction organization, and saving project costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

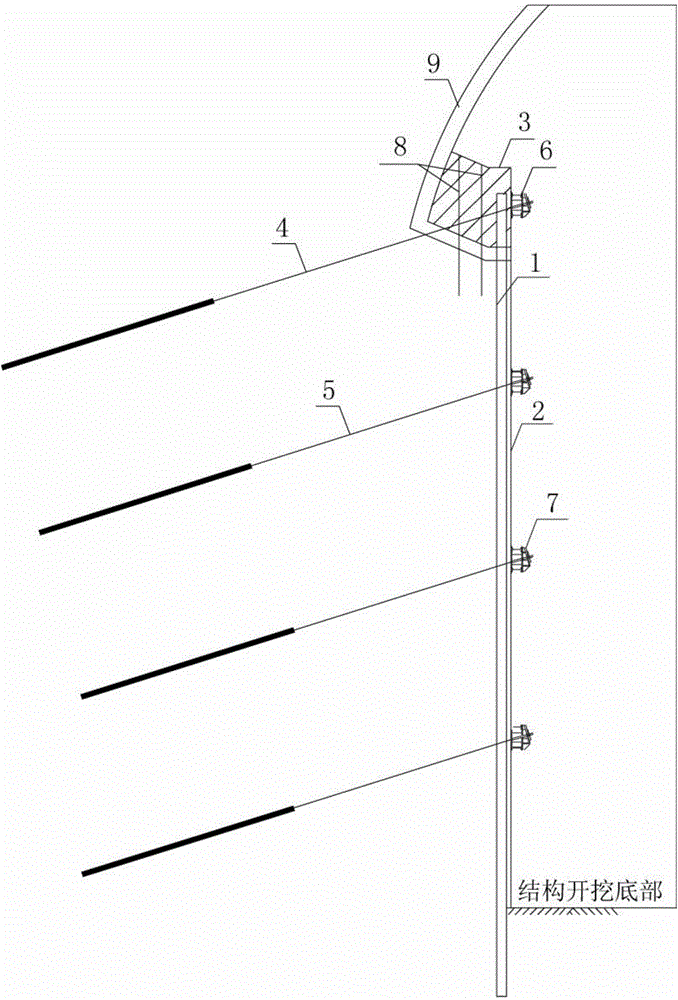

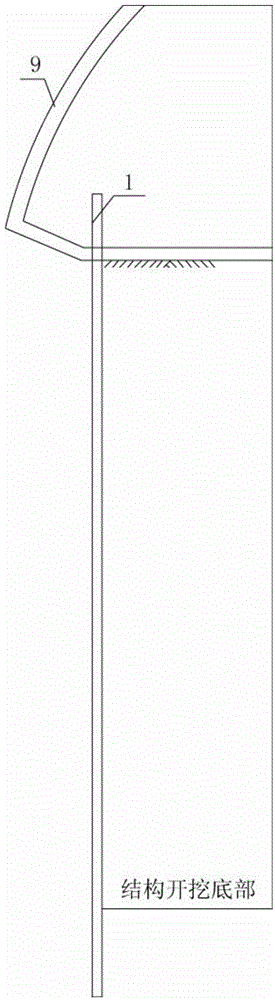

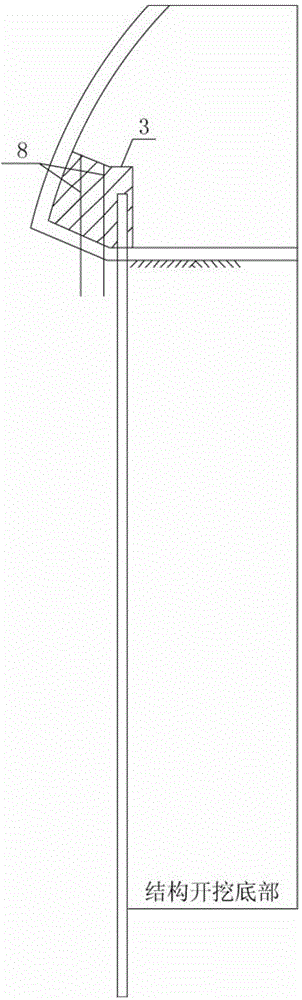

[0038] Such as figure 1 As shown, a rocky stratum submerged underground structure high side wall anchor tension initial support structure, including steel pipe pile 1, sprayed concrete surface layer 2, top ring beam 3, ring beam prestressed anchor cable 4, steel pipe pile prestressed Stress anchor cables 5, ring beam fixing parts 6, concrete fixing parts 7, the surface of the steel pipe pile 1 and the adjacent steel pipe pile 1 are closed by the shotcrete surface layer 2, and the top of the steel pipe pile 1 adopts the top ring beam 3 longitudinally The ring beam grouting steel pipe 8 is embedded in the top ring beam 3, the prestressed anchor cable 4 of the ring beam and the prestressed anchor cable 5 of the steel pipe pile are vertically arranged, and one end of the prestressed anchor cable 4 of the ring beam is installed on the top ring On the beam 3 and locked by the ring beam fixing part 6, the prestressed anchor cable 5 of the steel pipe pile is located under the ring bea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com