Outside-enhanced retaining supporting structure

A technology for supporting structures and retaining walls, which is applied to underwater structures, infrastructure engineering, water conservancy projects, etc., can solve problems such as hindering the operation of construction machinery, large length of construction, and damage to buildings and structures, so as to reduce the need for demolition of supports Or there is no need to remove the support, the rigidity and bearing capacity are large, and the effect of reducing the impact of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

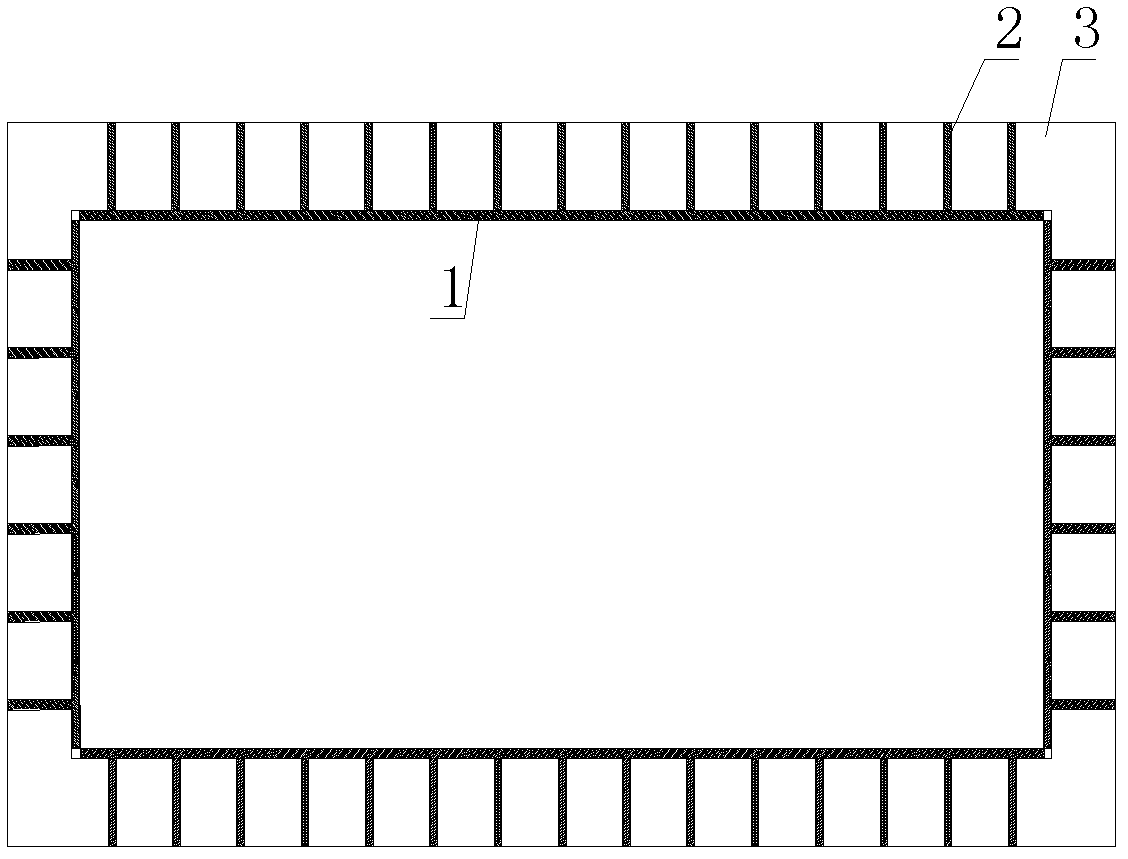

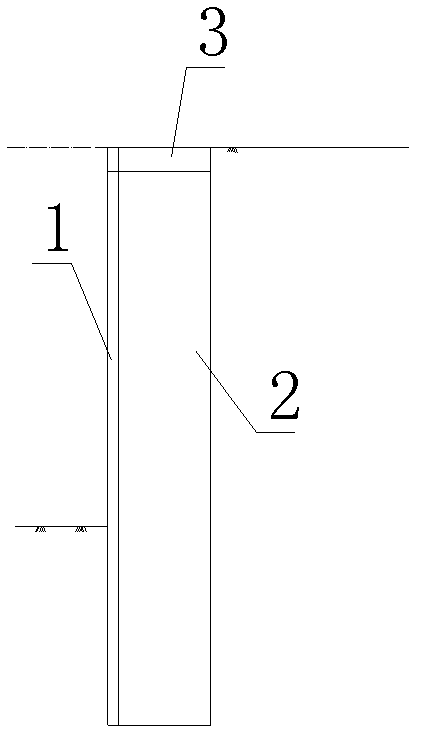

[0042] refer to figure 1 , image 3 As shown, the external reinforced soil retaining support structure of the present invention is a structure used for foundation pit support (if it is used for slope support, it does not need to be surrounded in a circle), including a continuous wall surrounded by support wall panels 1 In the retaining wall, there are longitudinal ribs 2 distributed on the outer side of the supporting wall panel 1, and a connecting plate 3 is arranged on the periphery of the supporting wall panel 1. The connection plate 3 in the example is ring-shaped, and the connection plate 3 can also be a non-closed structure, such as a continuous distance, which depends on the specific needs of the project;

Embodiment 2

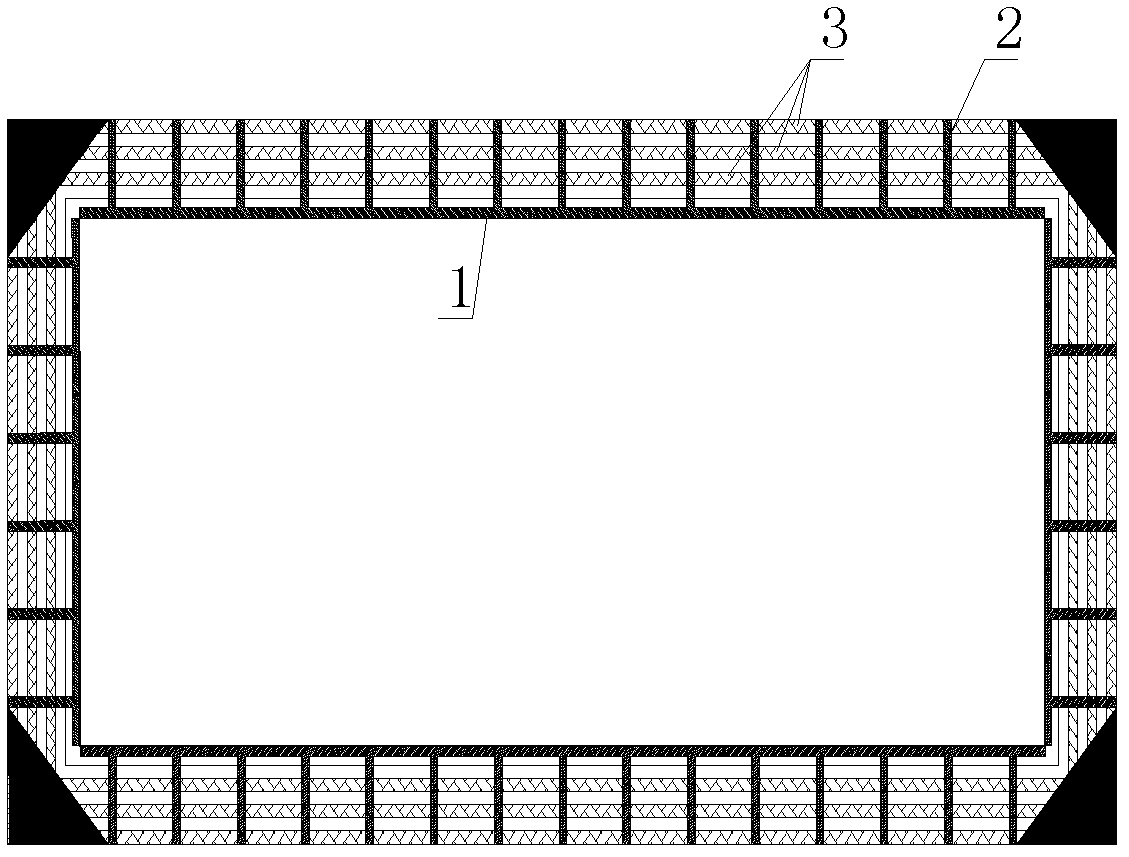

[0044] refer to figure 2 , Figure 4 As shown, the externally reinforced soil retaining support structure of the present invention includes a continuous retaining wall surrounded by support wall panels 1, longitudinal ribs 2 are distributed outside the support wall panels 1, and The connecting beam 4, the supporting wallboard 1, the longitudinal rib plate 2, and the connecting beam 4 together form a rigid whole. The connecting beam 4 in this embodiment is ring-shaped and has three rows in total. The connecting beam 4 is located at the upper and near end of the supporting wallboard 1. Outside; the connection beam 4 in the present invention can also be a non-closed structure, such as a continuous distance, which also depends on the specific needs of the project.

Embodiment 3

[0046] refer to figure 1 , Figure 5 As shown, the externally reinforced soil retaining support structure of the present invention includes a continuous retaining wall surrounded by support wall panels 1, longitudinal ribs 2 are distributed outside the support wall panels 1, and The annular connecting plate 3, the supporting wallboard 1, the longitudinal rib plate 2, and the annular connecting plate 3 together form a rigid whole. The connecting plate 3 in this embodiment is ring-shaped, and the connecting plate 3 is located outside the upper proximal end of the supporting wallboard 1. The connecting plate 3 is provided with a back tension anchor cable 5 to enhance the mechanical performance of the building structure system, and the back tension anchor cable 5 adopts a vertical prestressed anchor cable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com